Construction method for inverted arch of VI-level water-enriched surrounding rock tunnel

A technology of water-rich surrounding rock and construction method, applied in tunnels, tunnel linings, earthwork drilling and other directions, can solve problems such as high safety risks and low efficiency, and achieve the effects of high construction safety, improved construction progress and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

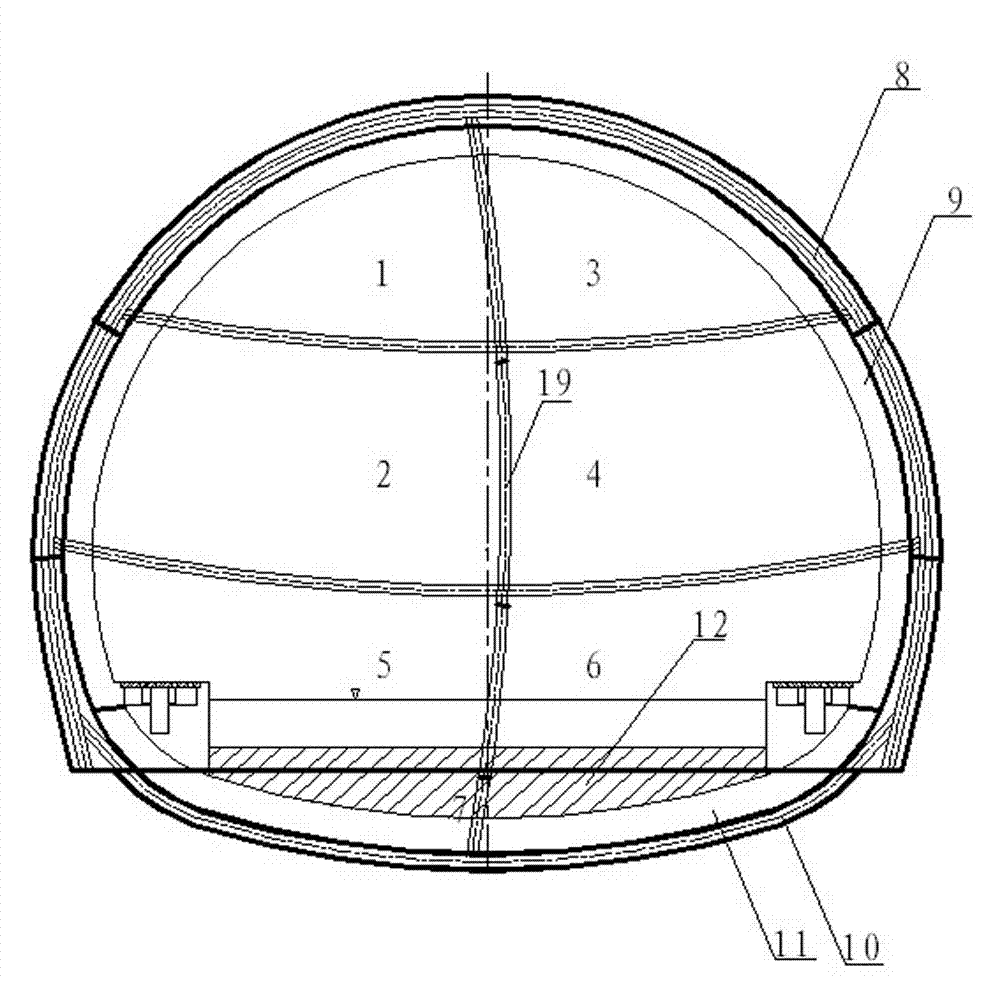

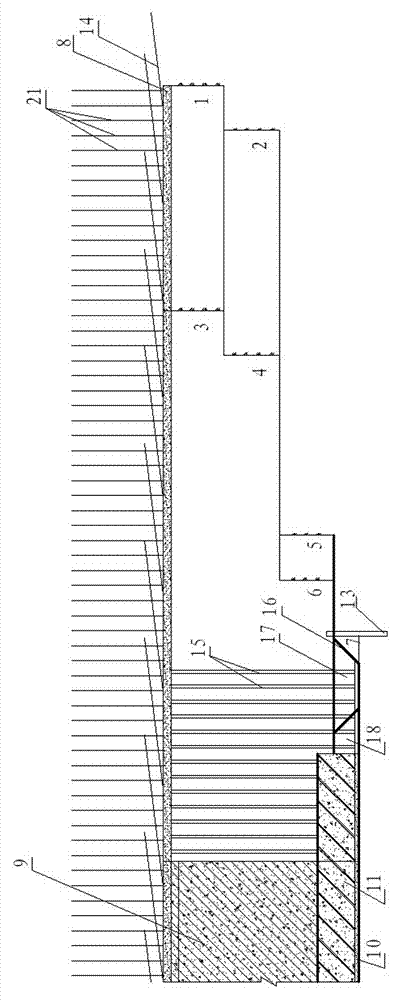

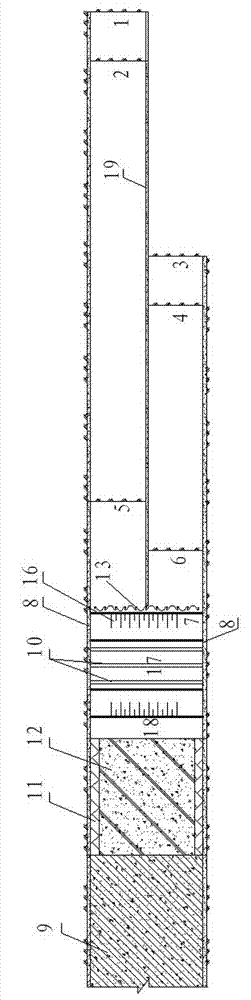

Image

Examples

Embodiment

[0026] Example: In view of the inverted arch construction of a tunnel on the Guangzhou-Zhuhai Railway, the tunnel is grade VI water-rich surrounding rock, and the construction is carried out according to the following construction methods.

[0027] Shotcrete 10cm to seal the face of the lower steps, pave stones 9m forward from the end of the inverted arch lining, and construct steel sheet piles at a distance of 9m from the inverted arch lining. The depth of the steel sheet piles is 5m, and the excavation distance is divided into left and right For the inverted arch within the range of 3-6m at the end of the constructed inverted arch lining, excavate the temporary slope with a slope ratio of 1:1, seal the temporary slope with 8cm shotcrete, erect the inverted arch trestle bridge, and construct the inverted arch at this section The initial support is connected to the long middle partition. Excavate the inverted arch within the range of 0-3m from the end of the constructed inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com