Optical fiber irradiation device

A technology for illuminating devices and optical fibers, which is applied to lighting devices, light guides of lighting devices, components of lighting devices, etc., can solve the problems of lens position shift, large tolerance of packaging substrate, and the need for cooling to reduce luminous efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Hereinafter, embodiments of the present invention will be described in detail.

[0052] The optical fiber irradiation device of the present invention has an optical fiber light source mechanism that condenses light from an LED light source through a lens and injects it into an optical fiber, and guides the light through the optical fiber to irradiate the light in spots.

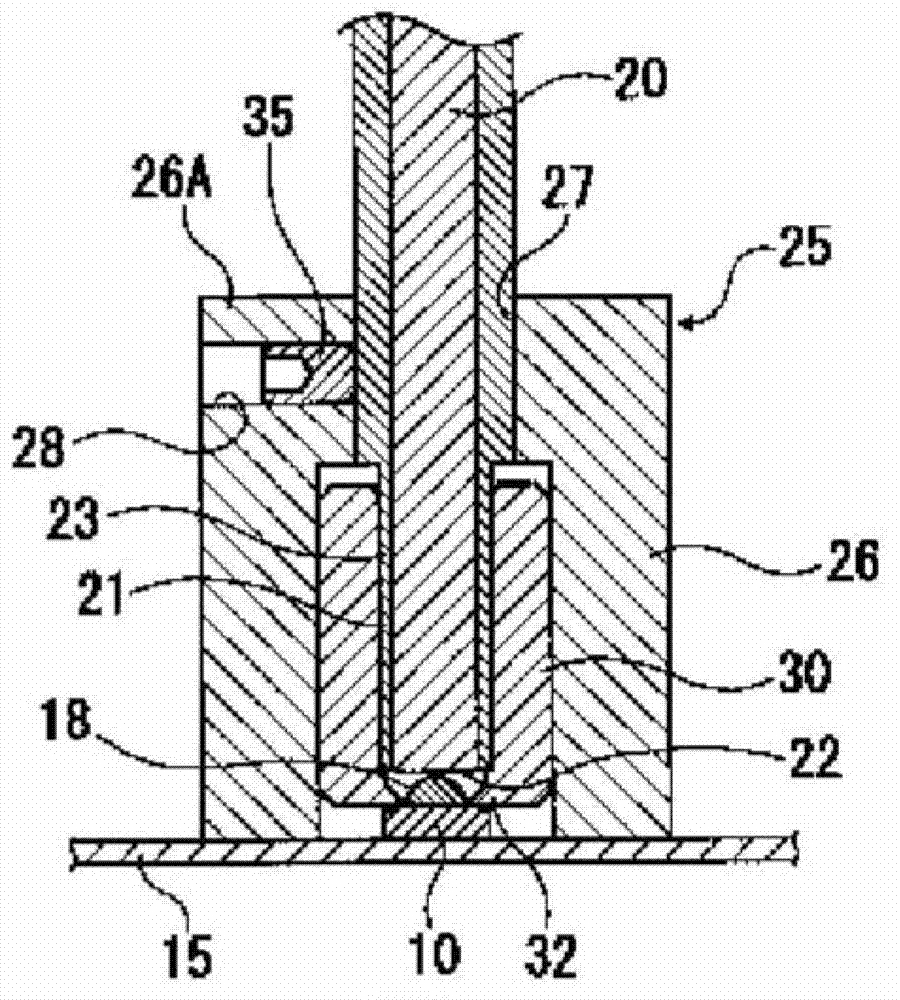

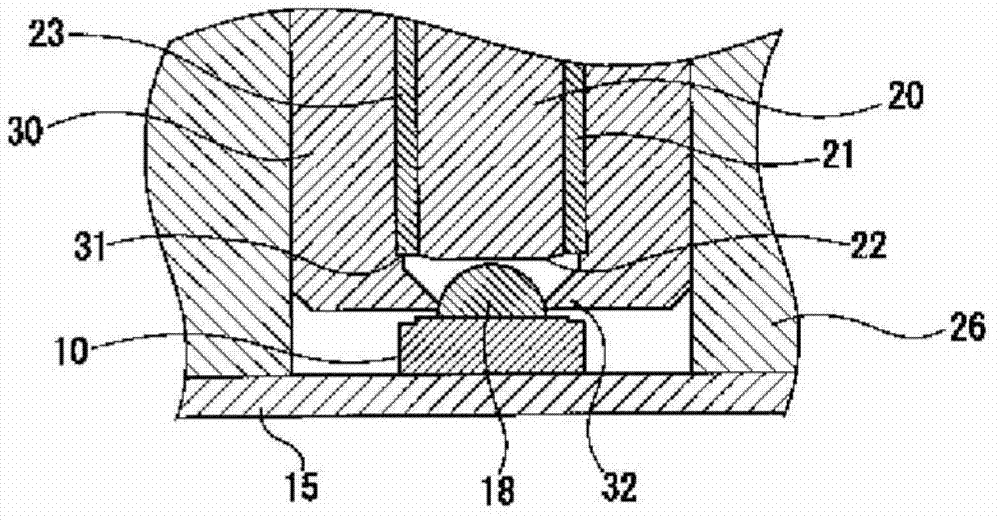

[0053] figure 1 It is an explanatory sectional view showing a schematic structure of an example of an optical fiber light source mechanism in the optical fiber irradiation device of the present invention, figure 2 will be figure 1 An enlarged cross-sectional view showing an enlarged portion of the fiber optic light source mechanism shown.

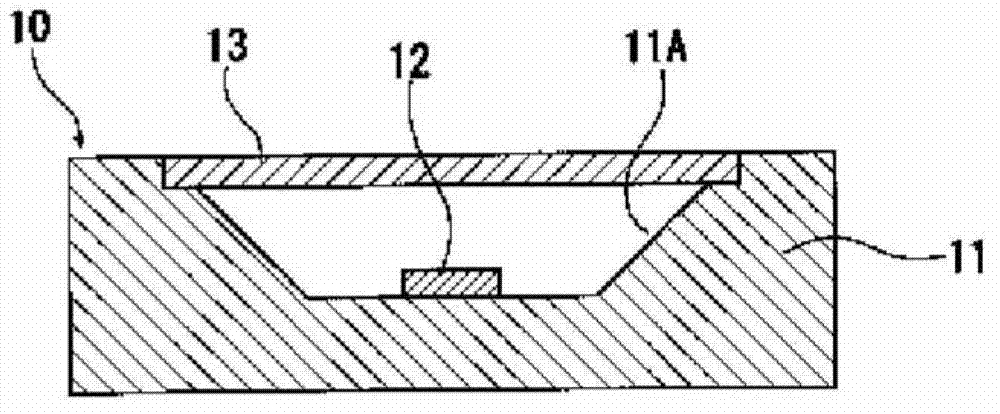

[0054] This optical fiber light source mechanism has an LED substrate 15, an LED light source arranged on one side of the LED substrate 15, a lens 18 for converging light emitted from the LED light source, and a lens 18 for guiding light from the LED light source...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com