Heat exchanger

A heat exchanger and heat exchange tube technology, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve uneven secondary distribution, unavoidable heat exchange tube flow, open hole structure process complex issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The present invention will be further described below in conjunction with the drawings and specific embodiments.

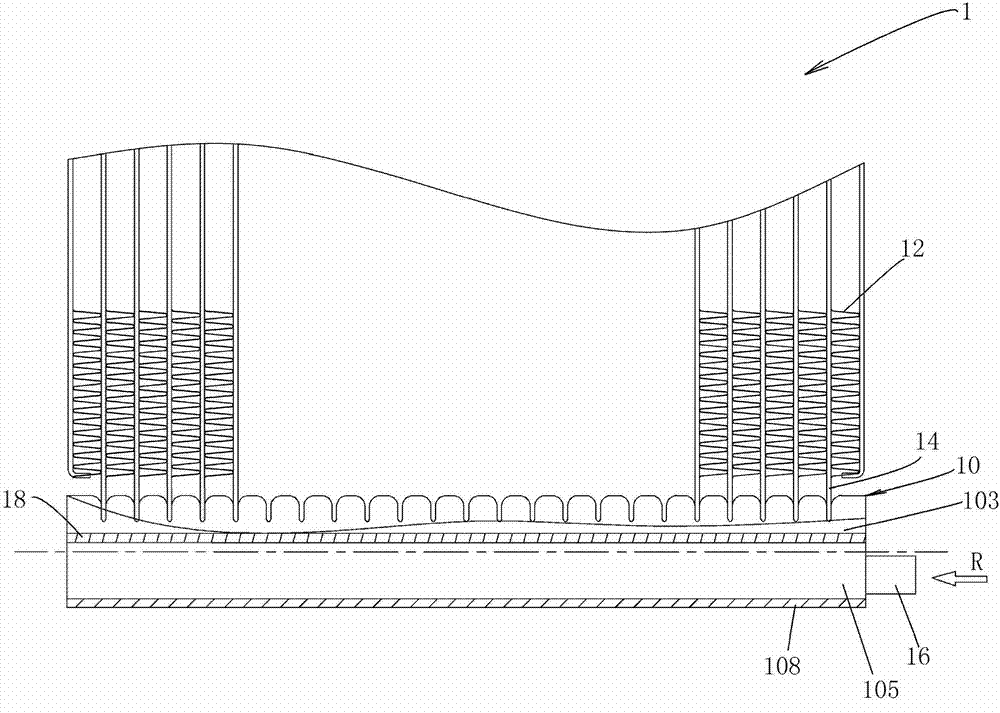

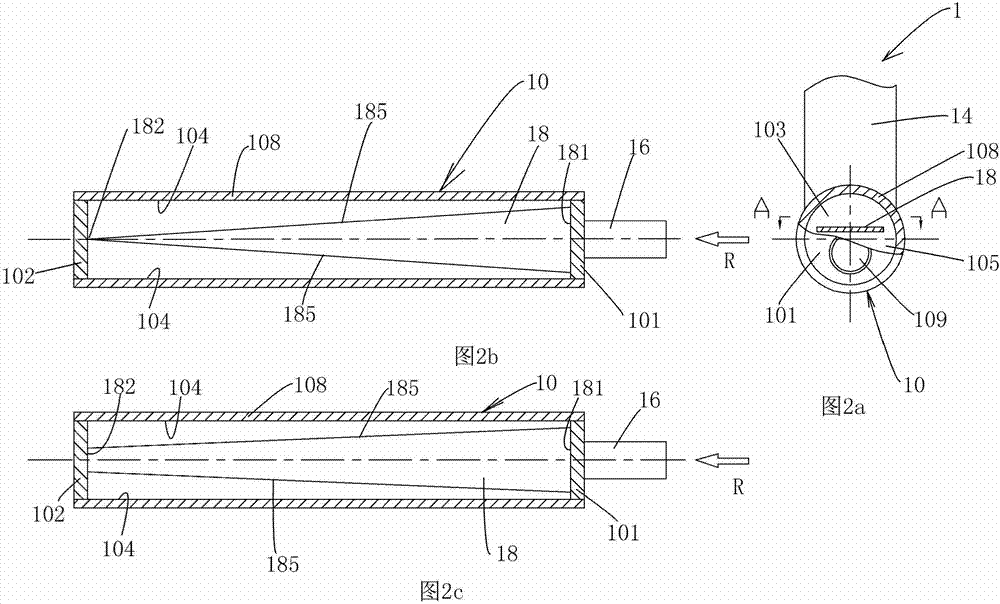

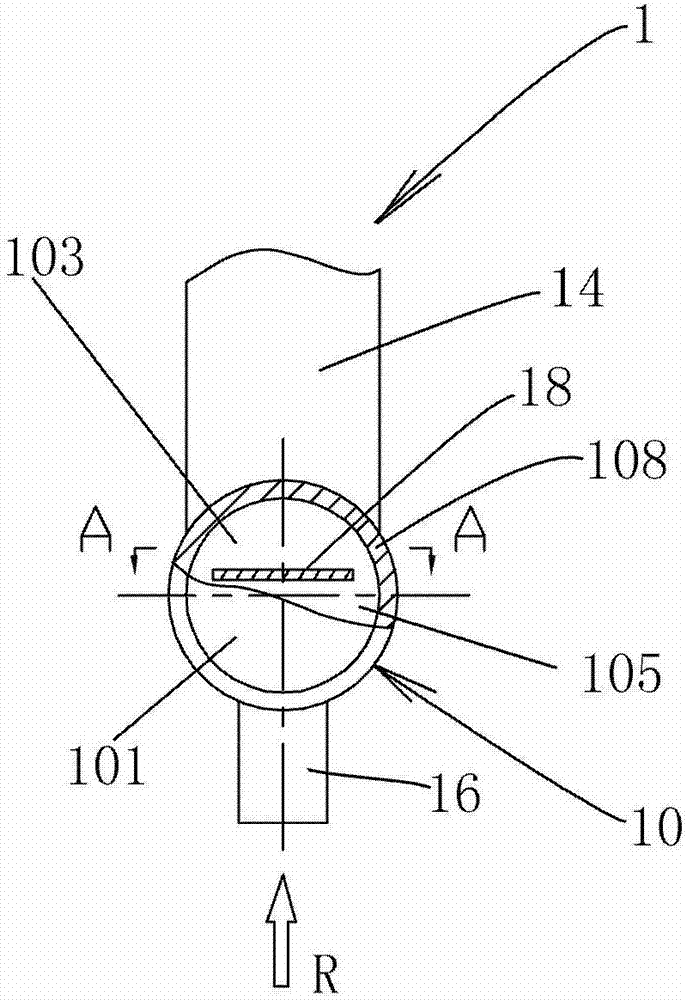

[0083] figure 1 Shows a heat exchanger according to an embodiment of the invention, Figure 2a Shows the heat exchanger with the connecting pipe arranged on the closure of the header, Figure 2b with 2c Two embodiments of the dispenser 18 are shown.

[0084] Reference Figure 1 to 2c , The heat exchanger 1 such as the microchannel heat exchanger according to the present invention includes: a header 10; a heat exchange tube 14, the end of the heat exchange tube 14 is connected to the tube wall 108 of the header 10 and the The heat exchange tube 14 is in fluid communication with the header 10; the fin 12 arranged between the heat exchange tubes 14; the connecting tube 16 connected to the header 10; the end caps 101 and 102 that close the ends of the header 10 The distributor 18 disposed inside the header 10, a gap is provided between the edge 185 of the distributo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com