Pressure sensor and pressure sensing method

A sensing method and pressure sensing technology, applied in fluid pressure measurement involving magnet displacement, etc., can solve problems such as ignition, damage, and low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

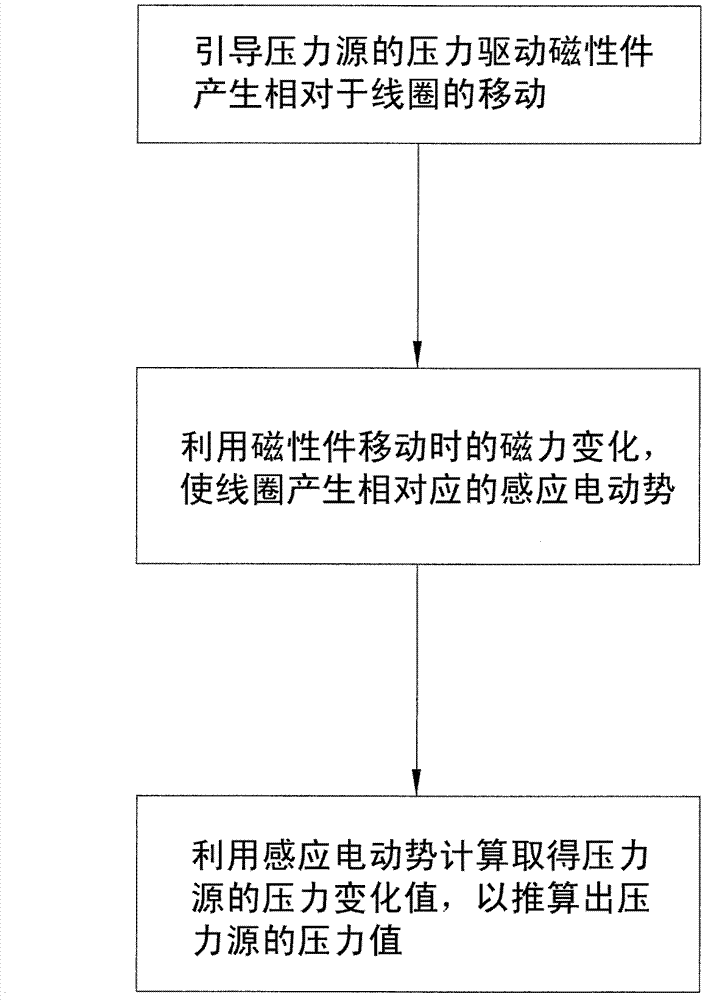

[0046] The pressure sensing method provided by the present invention is used to sense the pressure of a pressure source, and the method includes the following steps:

[0047] A) directing the pressure of the pressure source to drive a magnetic member for generating a magnetic force close to or away from a coil of conductive material;

[0048] B) Using the change of magnetic force when the magnetic part moves, the coil generates corresponding induced electromotive force.

[0049] C) Using the induced electromotive force to calculate the pressure change value of the pressure source, so as to calculate the pressure value of the pressure source.

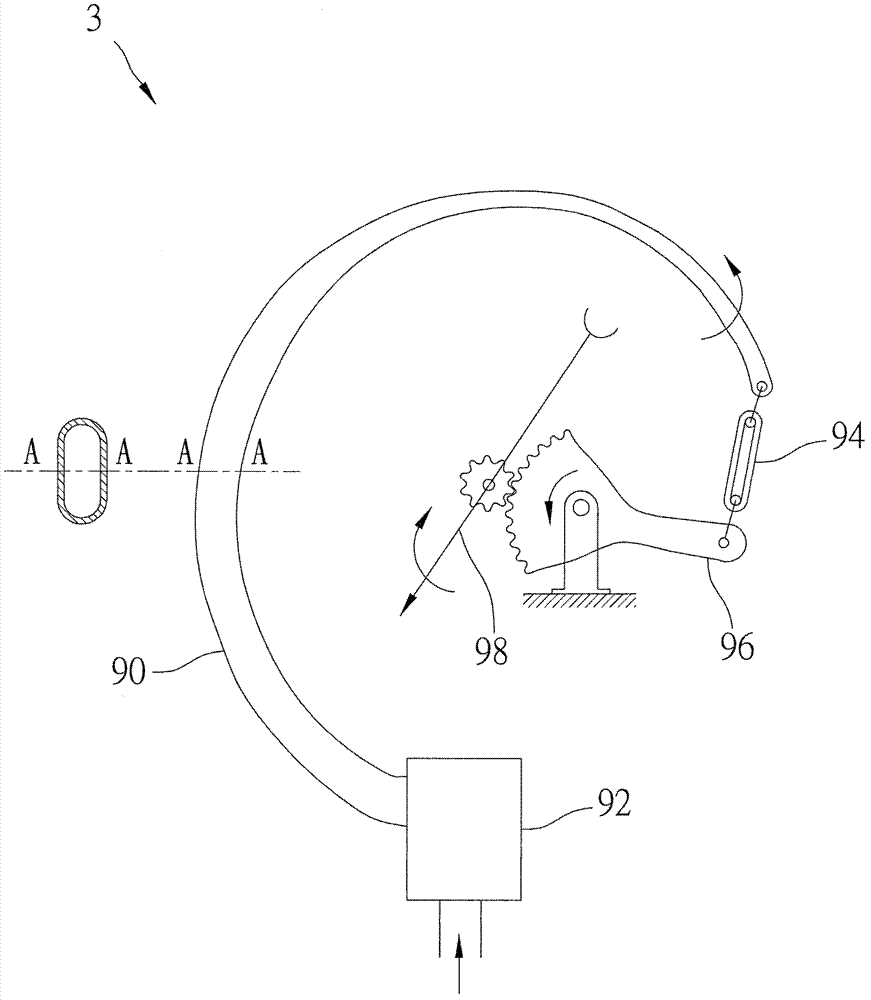

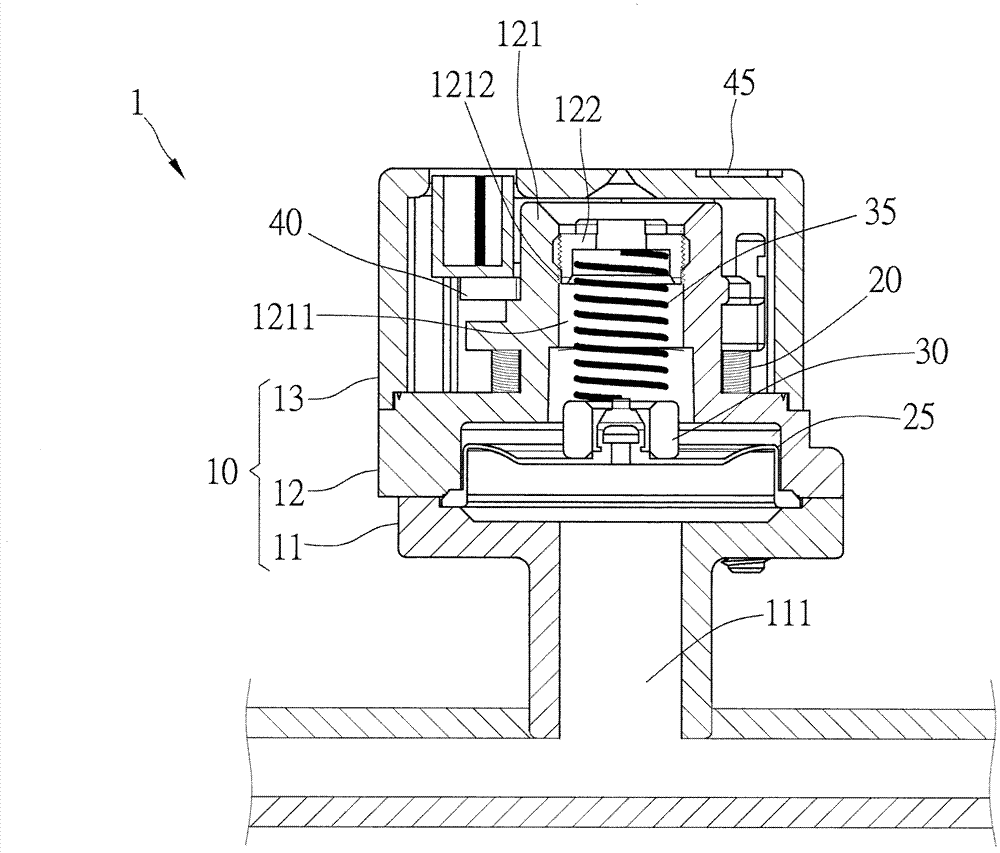

[0050]According to the above method, the present invention provides a pressure sensing device, which includes a housing, a coil, a stretchable film layer, and a magnetic element. Wherein, the casing has a detection hole, and one end of the detection hole is used to contact the pressure source; the coil is made of conductive material and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com