Device and method for testing performance of high-temperature pipeline heat insulation clad material

A technology of coating materials and testing devices, which is applied in the field of testing devices for the performance effect of heat insulation coating materials for high-temperature exhaust pipes of large ships, can solve the problems of large investment, one-sided test results, waste of manpower and materials, etc., and achieve the goal of measuring temperature High, easy to move and install, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

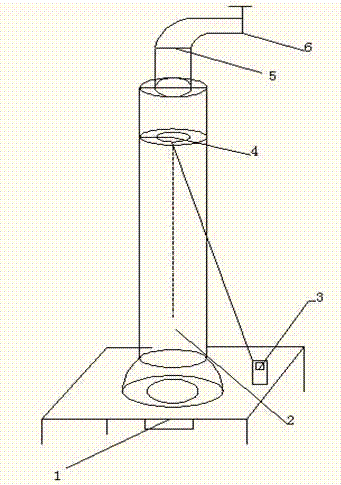

[0015] Such as figure 1 The present invention shown includes a combustion furnace (1). The hot air outlet of the combustion furnace is connected with a heating pipe (2). The telescopic cover sheet (6) for the air outlet flow rate, the inner wall and the outer wall of the heating tube are provided with temperature measuring points, and the temperature measuring points are also connected with thermocouple thermometers (3).

[0016] The heating device is a combustion furnace device, and the combustion furnace device is a natural gas furnace or a gas furnace or an acetylene gas furnace or other combustion heat source devices.

[0017] The heating pipes are cast iron pipes, wrought iron leather pipes or carbon steel pipes, and the heating pipes can be straight or straight with elbows or straight with branch pipes.

[0018] The heat flow discharge regulating pipe is a white iro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com