Finite element-based intelligent analysis method for strength of pipeline with defects

An intelligent analysis and finite element technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve a lot of time problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

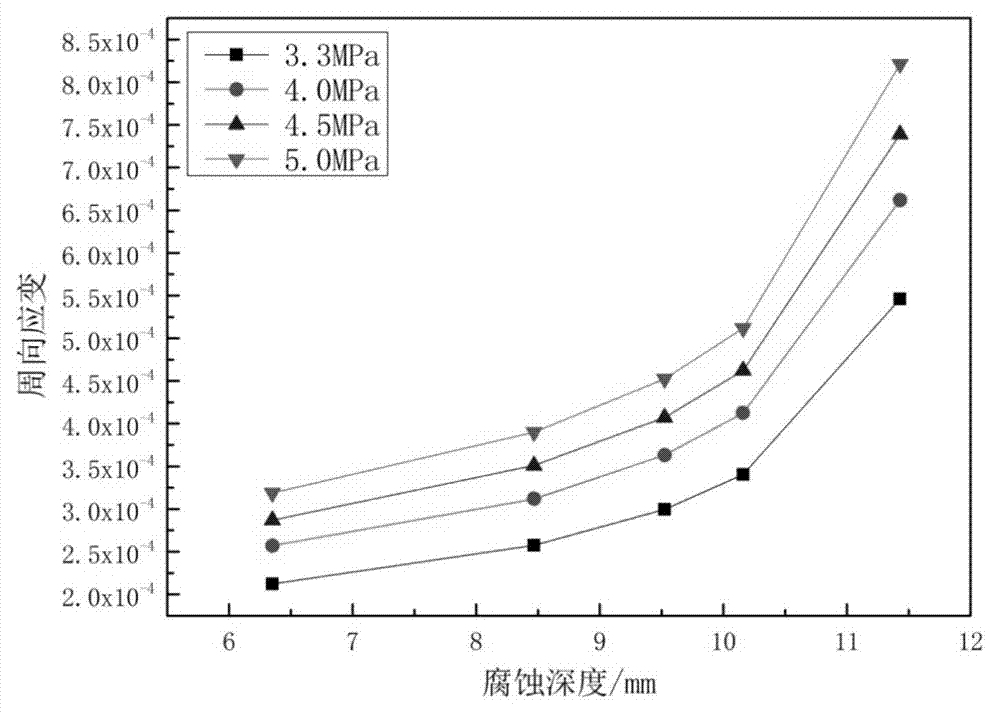

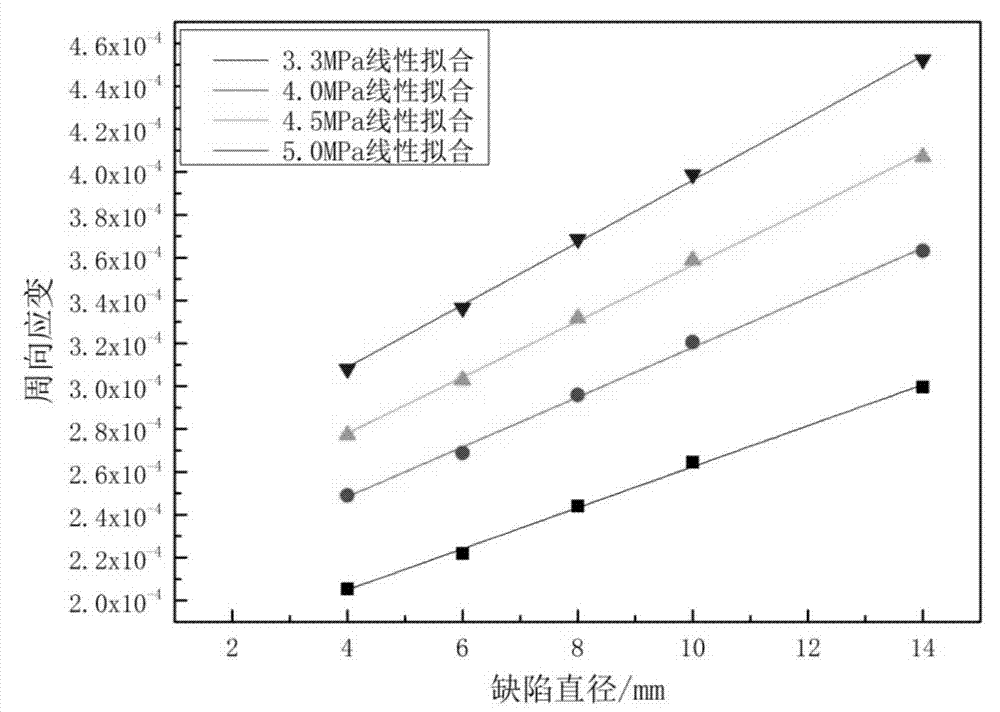

Examples

Embodiment 1

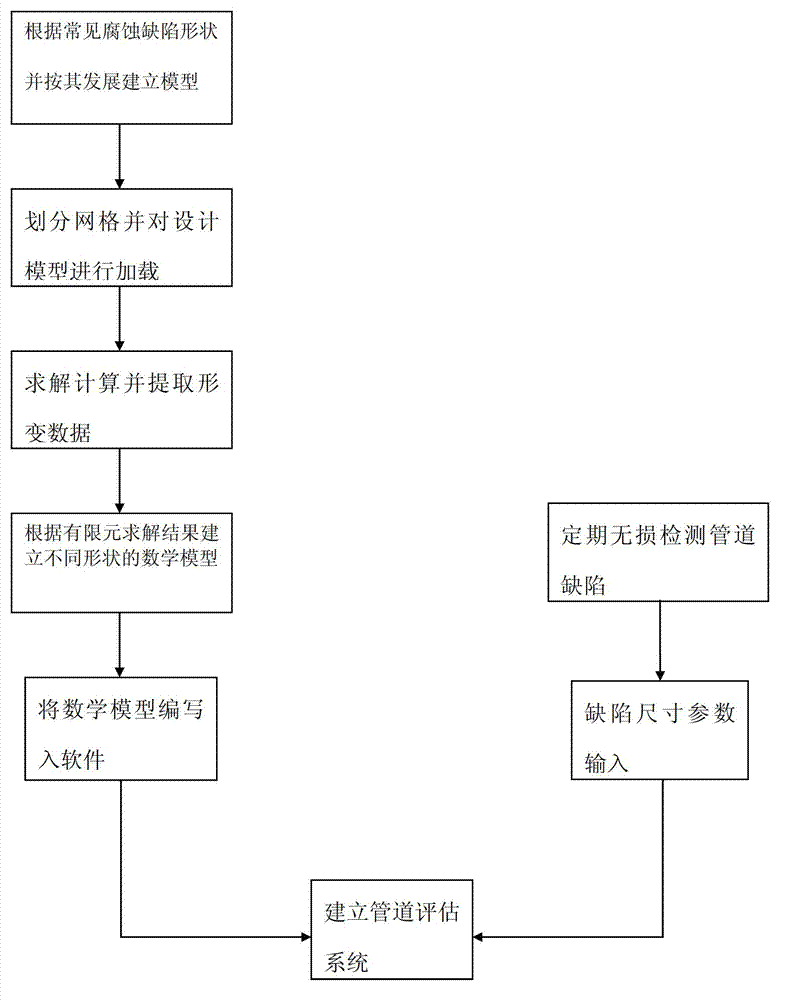

[0036] An intelligent analysis method for the strength of pipelines with defects based on finite elements, the process can be found in figure 1 , including the following steps:

[0037] 1) Simplification of the design model

[0038] Referring to "GB / T 18590-2001 Corrosion Pitting Evaluation Method for Metals and Alloys", several common forms of volumetric internal corrosion defects are simplified into regular cylindrical, crock, spherical and conical types. This patent In the example, the cylindrical defect shape is taken as an example. The oil and gas pipeline material used in this model is X60, and the pipeline specification is Φ356×12.7mm. According to St. Venant’s principle, in order to eliminate boundary effects, the length of the finite element model is 3 to 5 times the diameter of the pipeline, and the length of the pipeline is 1000mm. 1 / 4 pipeline model can be found in figure 2 .

[0039] 2) Finite element mesh division

[0040] After the geometric model is estab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com