Anti-fake film and manufacturing method thereof

A technology of anti-counterfeiting film and brightening layer, which is applied to chemical instruments and methods, identification devices, instruments, etc., can solve the problems of not forming three-dimensional anti-counterfeiting and not seeing anti-counterfeiting features, and achieve the effect of increasing anti-counterfeiting features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, the present application will be described in detail through embodiments and with reference to the accompanying drawings.

[0028] Anti-counterfeiting film technology is a new type of optical anti-counterfeiting technology, which has a high public recognition effect. It is mainly used for anti-counterfeiting of banknotes, securities, passports, tax stamps and other high-end security products. Its main purpose is to integrate holographic and optical variable anti-counterfeiting features, achieve multiple anti-counterfeiting effects through special structural design, and further improve the anti-counterfeiting level.

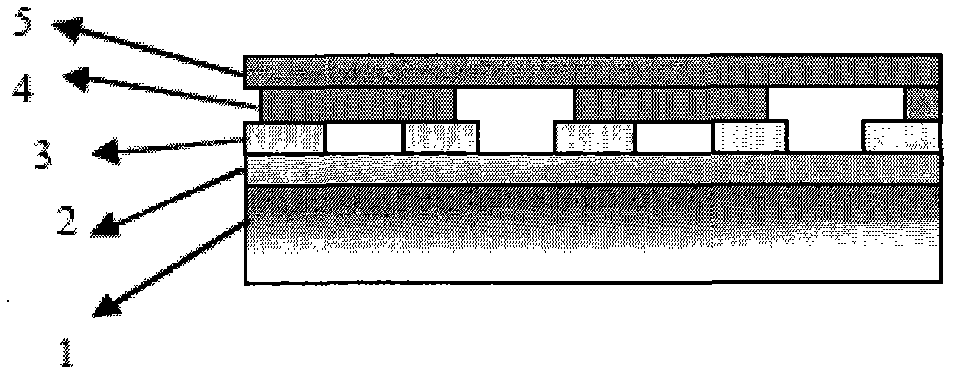

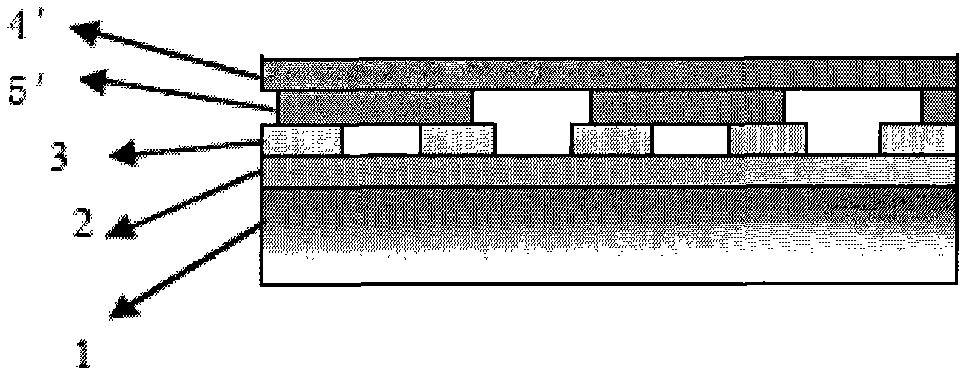

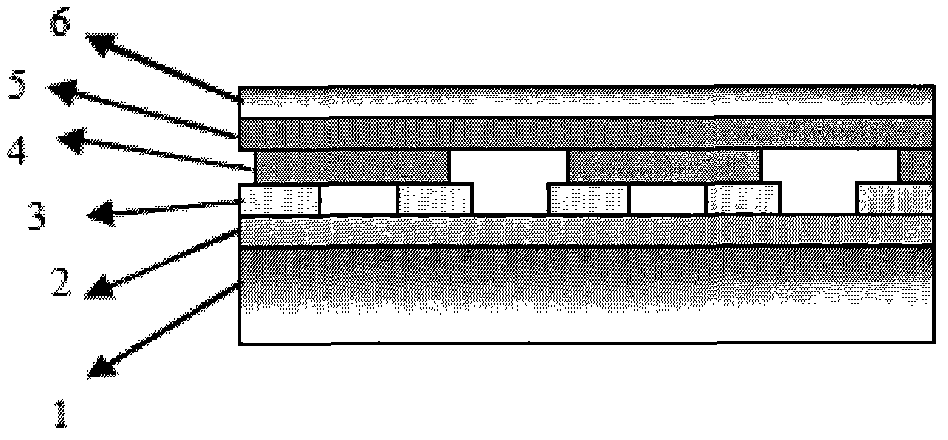

[0029] figure 1 and figure 2 The structural schematic diagrams of the anti-counterfeiting films according to the embodiments of the present application are respectively shown. As shown in the figure, the anti-counterfeiting film includes a substrate layer 1 stacked in sequence, a holographic imaging layer 2 with a holographic image, a partia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com