Electronic module, light emitting device and manufacture method of electronic module

A technology for electronic modules and molds, applied in circuit thermal devices, printed circuit manufacturing, circuits, etc., can solve the problems of damage to lighting devices, low stability of electronic modules, and high thermal resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

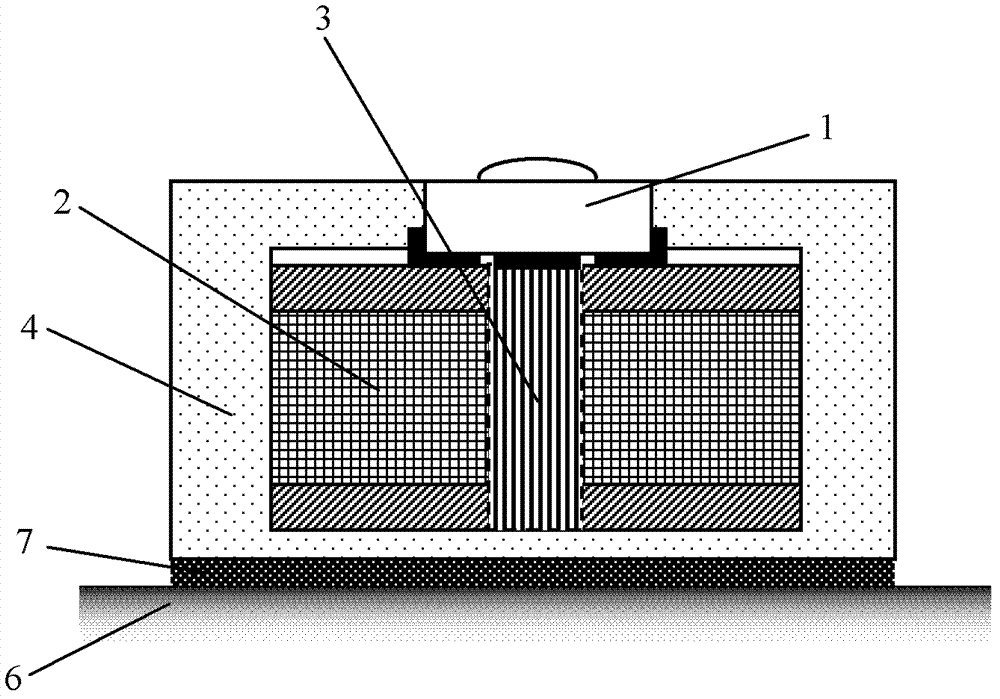

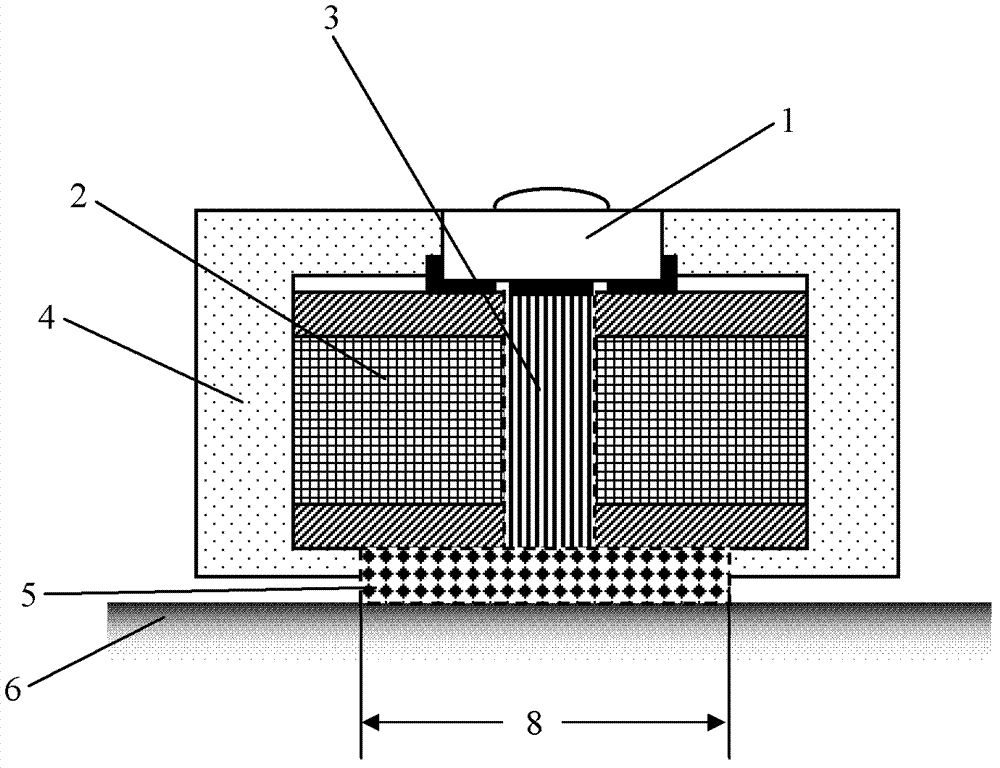

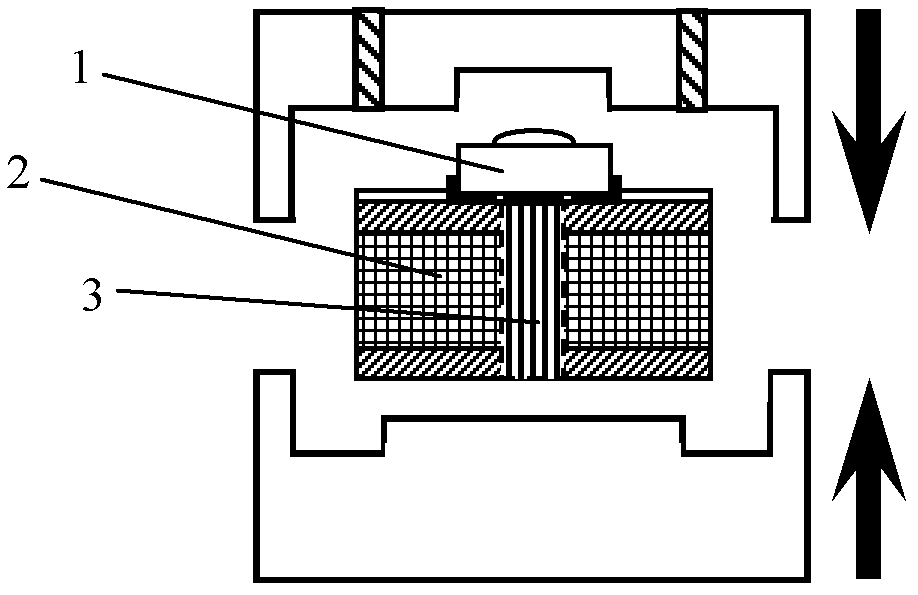

[0036] figure 2 A cross-sectional view of an electronic module according to the invention is shown. The circuit board 2 on which the heat source 1, such as an LED, is mounted can be, for example, an FR4 printed circuit board, which is a double-layer circuit board and has low thermal conductivity similar to conventional plastics, with a thermal conductivity of about 0.2W / m*K . A through thermal hole 3 is formed on the circuit board 2 , and the heat source 1 is located directly above the thermal hole 3 and is in direct thermal contact with it, so that the heat emitted by the heat source 1 can be guided to the outside of the circuit board 2 through the thermal hole 3 . In order to obtain a good heat conduction effect, the thermal hole 3 is usually filled with a heat conduction medium. The encapsulation material 4 for encapsulating the circuit board 2 is usually a hard plastic, and its thermal resistance can be equivalent to that produced by a material with a thermal conductivi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com