Patents

Literature

32results about "Treatment using electric/magnetic/electromagnetic fields" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oriented, aminosilane-coated film capable of structuring by means of electromagnetic radiation and composed of thermoplastic polyester for the production of selectively metallized films

InactiveUS20050064711A1Improve adhesionLow production costInsulating substrate metal adhesion improvementSynthetic resin layered productsPolyesterFilm base

The invention relates to a single- or multilayer, oriented, film coated with an aminosilane compound and composed of polyester which comprises an additive which, on irradiation with electromagnetic radiation, forms metal nuclei on which further metal can be deposited in further steps of the process. The invention further relates to a process for producing this film and to its use in printed circuit boards, ribbon cables, smart cards, RFID labels, membrane keyboards, and film-based circuits of any type.

Owner:MITSUBISHI POLYESTER FILM

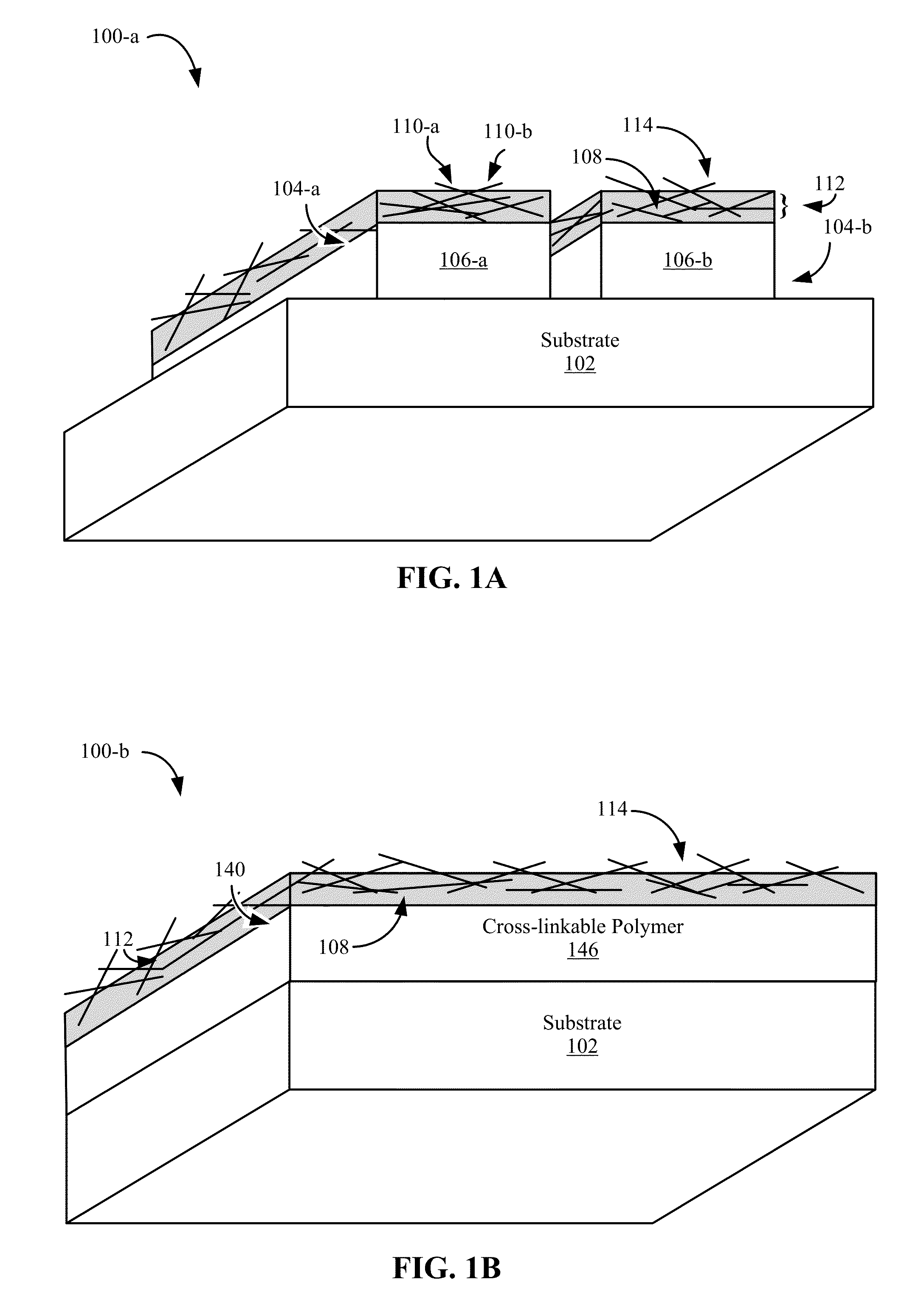

Composite Conductive Films with Enhanced Thermal Stability

ActiveUS20150038033A1Enhanced hardness propertyImprove temperature stabilityNanoinformaticsApparatus for heat treatmentCross-linkNanowire

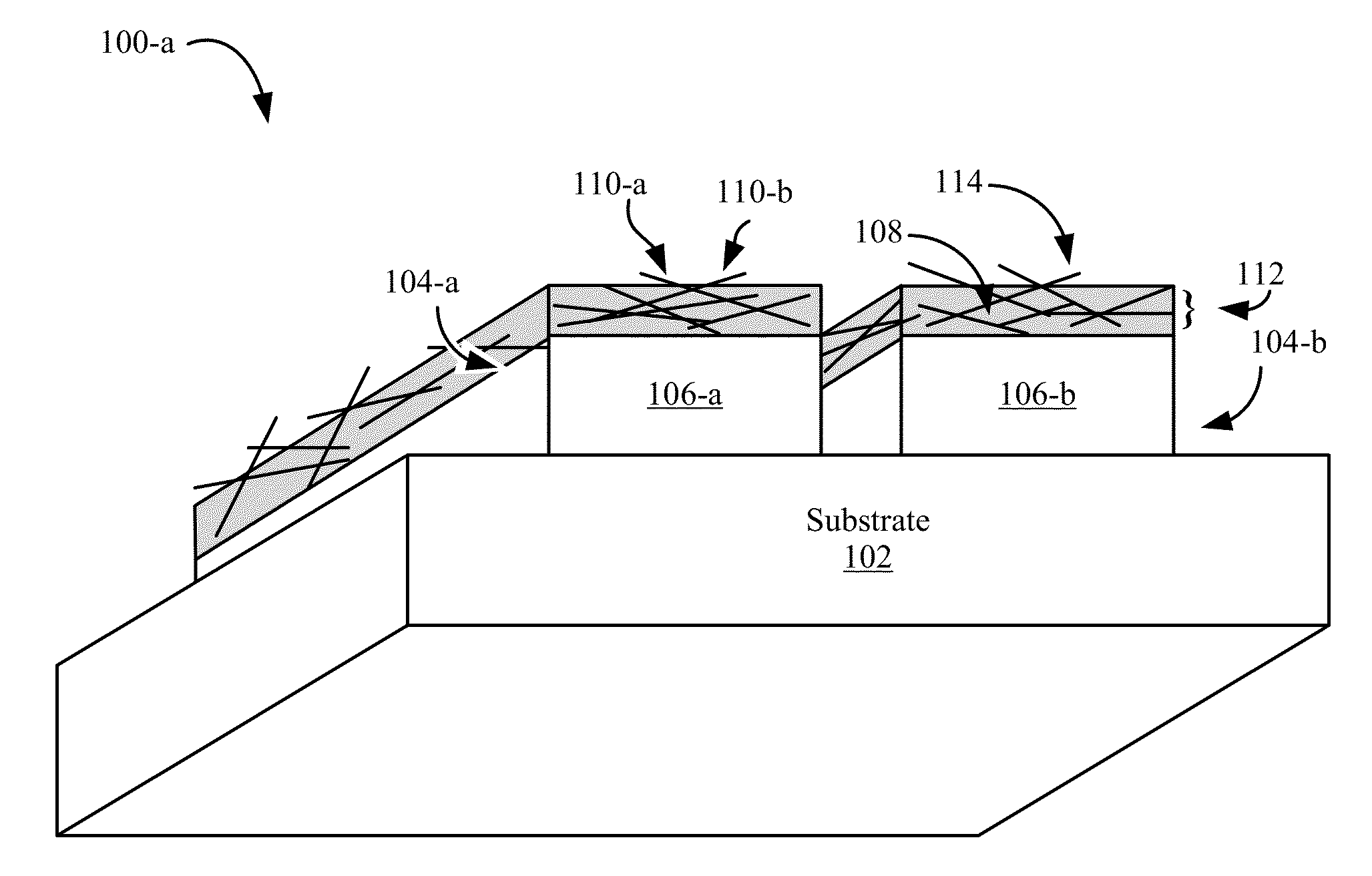

A composite conductive film is provided that includes a layer of cross-linked polymer having a surface and an inorganic mesh comprising a plurality of nanowires of an inorganic material. The nanowires are, in isolated form, characterized by a first conductivity stability temperature. Further, the plurality of nanowires is embedded within at least a region of the layer of cross-linked polymer, where the region is continuous from the surface of the layer of cross-linked polymer. The layer of cross-linked polymer and the inorganic mesh are arranged to form the composite conductive film having a second conductivity stability temperature that is greater than the first conductivity stability temperature.

Owner:SINOVIA TECH

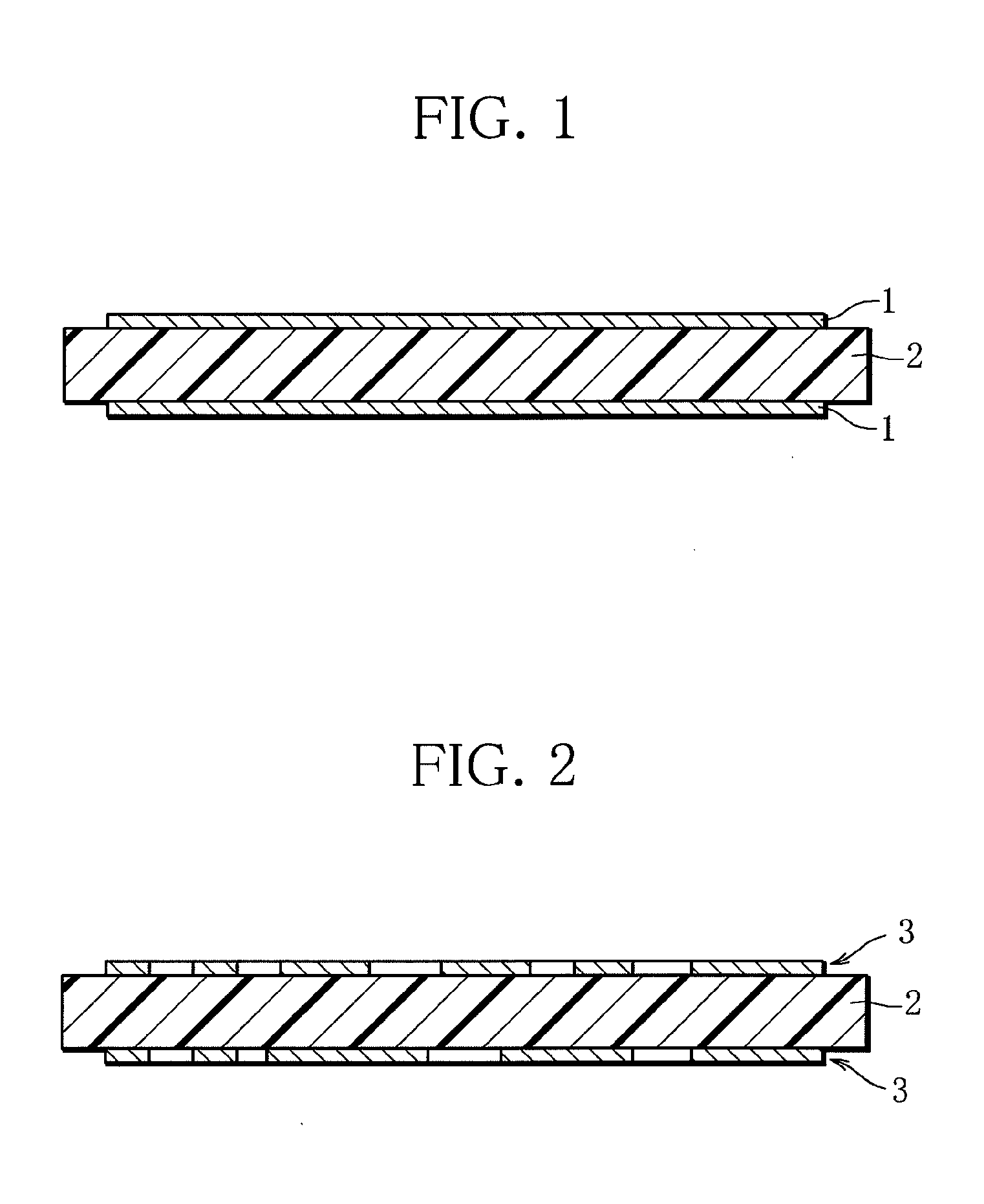

Multilayer, oriented film capable of structuring by means of electromagnetic radiation and composed of thermoplastic polyester, for the production of selectively metallized films

InactiveUS7112365B2Good orientationLow production costRecord information storageMagnetic recordingPolyesterFilm base

The invention relates to a multilayer, oriented film, in which at least one layer comprises a polyester which comprises an additive which, on irradiation with electromagnetic radiation, forms metal nuclei on which further metal can be deposited in further steps of the process. The invention further relates to a process for the production of this film and to its use in printed circuit boards, ribbon cables, smart cards, RFID labels, membrane keyboards, and film-based circuits of any type.

Owner:MITSUBISHI POLYESTER FILM

Multilayer, oriented film capable of structuring by means of electromagnetic radiation and composed of thermoplastic polyester, for the production of selectively metallized films

InactiveUS20050069689A1Good orientationLow production costRecord information storageMagnetic recordingPolyesterFilm base

The invention relates to a multilayer, oriented film, in which at least one layer comprises a polyester which comprises an additive which, on irradiation with electromagnetic radiation, forms metal nuclei on which further metal can be deposited in further steps of the process. The invention further relates to a process for the production of this film and to its use in printed circuit boards, ribbon cables, smart cards, RFID labels, membrane keyboards, and film-based circuits of any type.

Owner:MITSUBISHI POLYESTER FILM

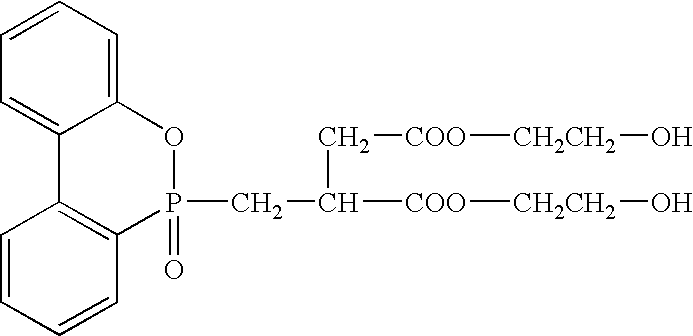

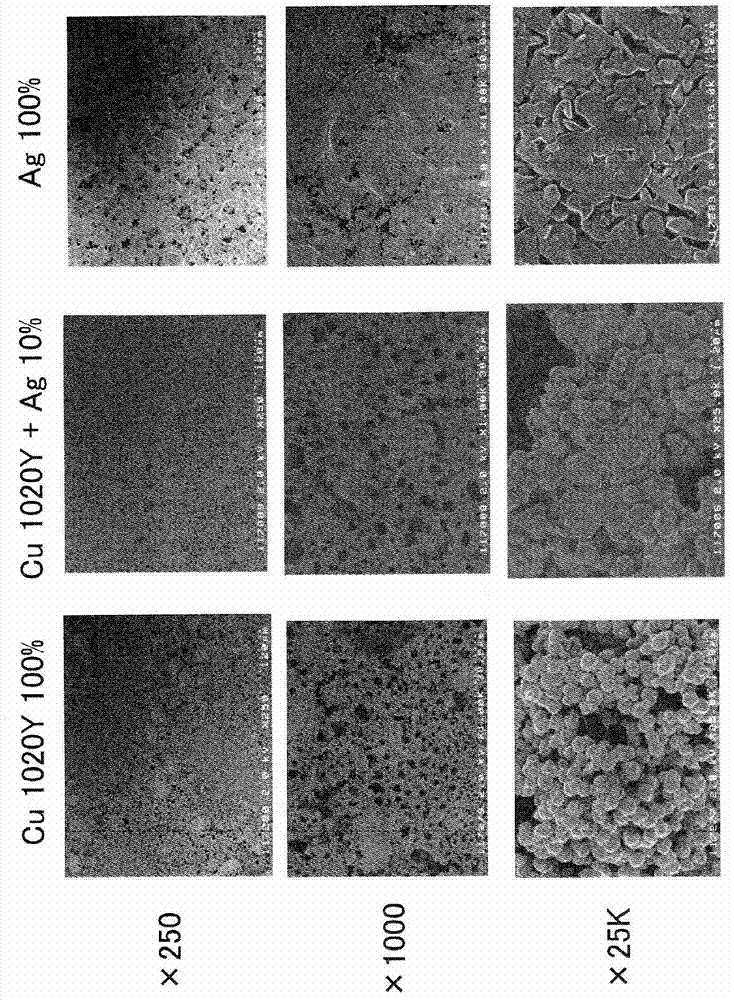

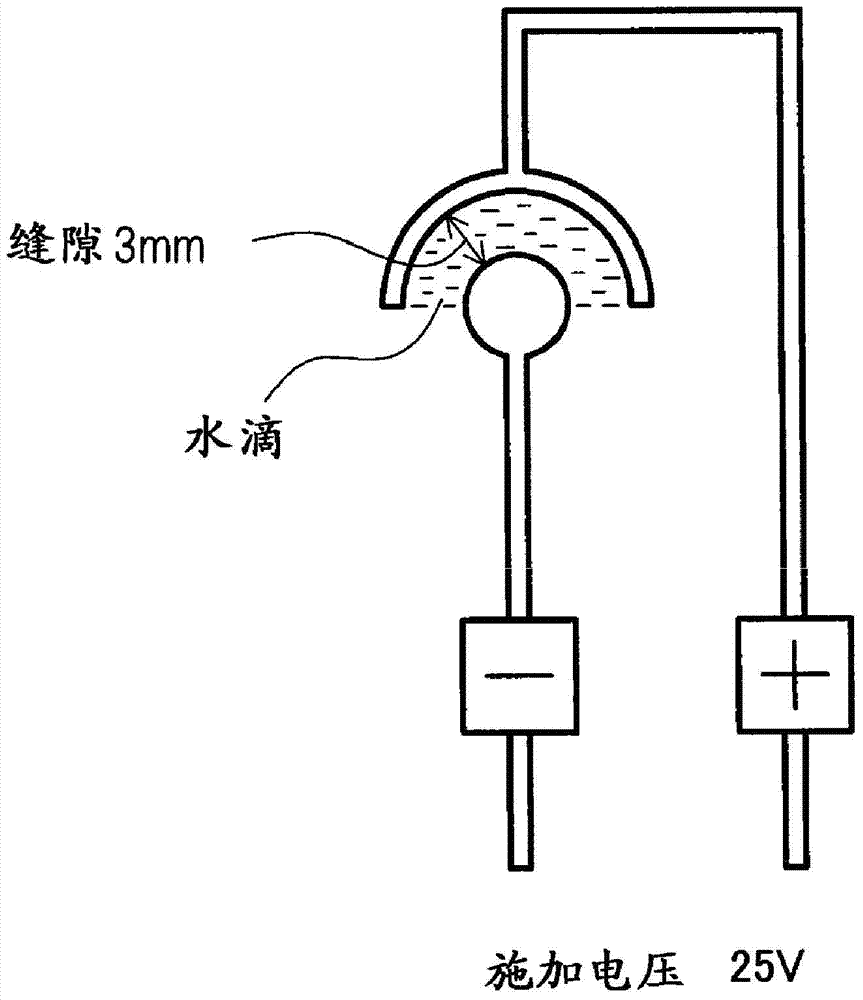

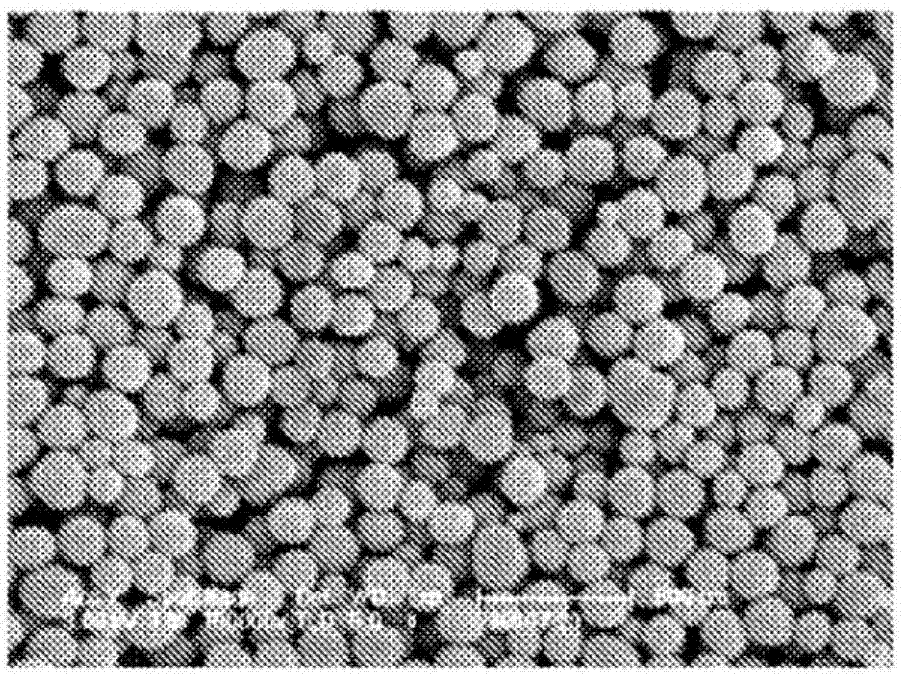

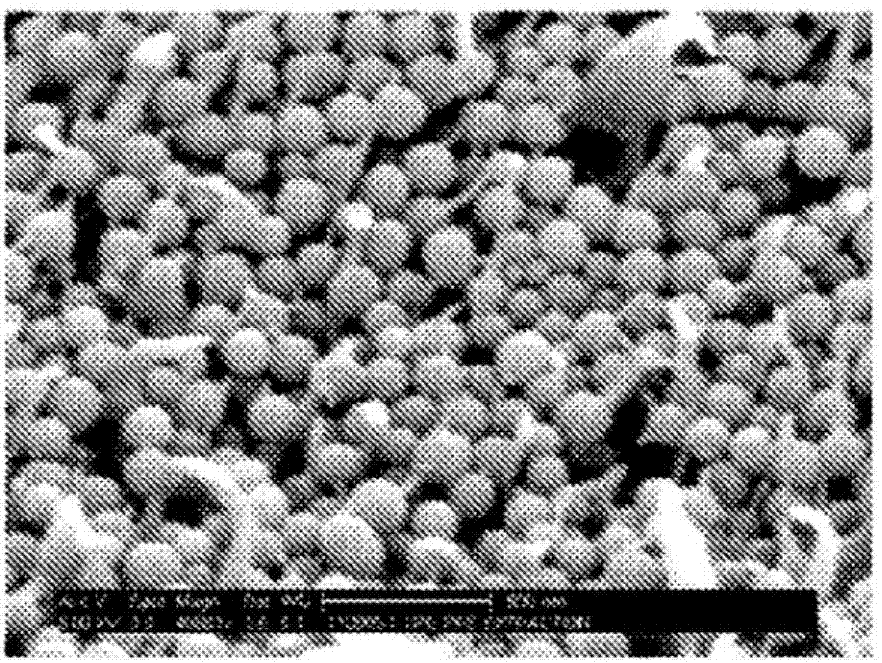

Copper particulate dispersion, conductive film forming method, and circuit board

InactiveUS20160007455A1Lower resistanceWell formedAdditive manufacturingConductive materialParticulatesCopper oxide

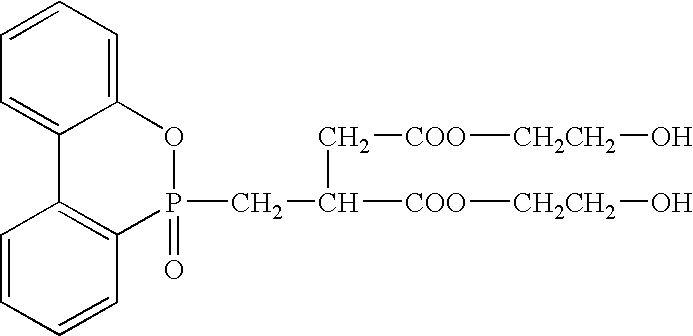

Provided is a copper particulate dispersion that can facilitate the formation of a conductive film with low electric resistance by photo-sintering. A copper particulate dispersion includes a dispersion vehicle and copper particulates dispersed in the dispersion vehicle. The copper particulate dispersion contains a sintering promoter. The sintering promoter is a compound that removes copper oxide from copper at a temperature higher than ambient temperature. The sintering promoter thereby removes surface oxide coatings from the copper particulates during the photo-sintering of the copper particulates.

Owner:ISHIHARA CHEM

Oriented, aminosilane-coated film capable of structuring by means of electromagnetic radiation and composed of thermoplastic polyester for the production of selectively metallized films

InactiveUS7261944B2Improve adhesionGood orientationRecord information storagePrinted circuit secondary treatmentPolyesterFilm base

The invention relates to a single- or multilayer, oriented, film coated with an aminosilane compound and composed of polyester which comprises an additive which, on irradiation with electromagnetic radiation, forms metal nuclei on which further metal can be deposited in further steps of the process. The invention further relates to a process for producing this film and to its use in printed circuit boards, ribbon cables, smart cards, RFID labels, membrane keyboards, and film-based circuits of any type.

Owner:MITSUBISHI POLYESTER FILM

Method for reducing thin films on low temperature substrates

ActiveUS8945686B2Lithography/patterningAlkali metal silicate coatingsMaterials scienceReducing agent

Owner:NCC NANO LLC

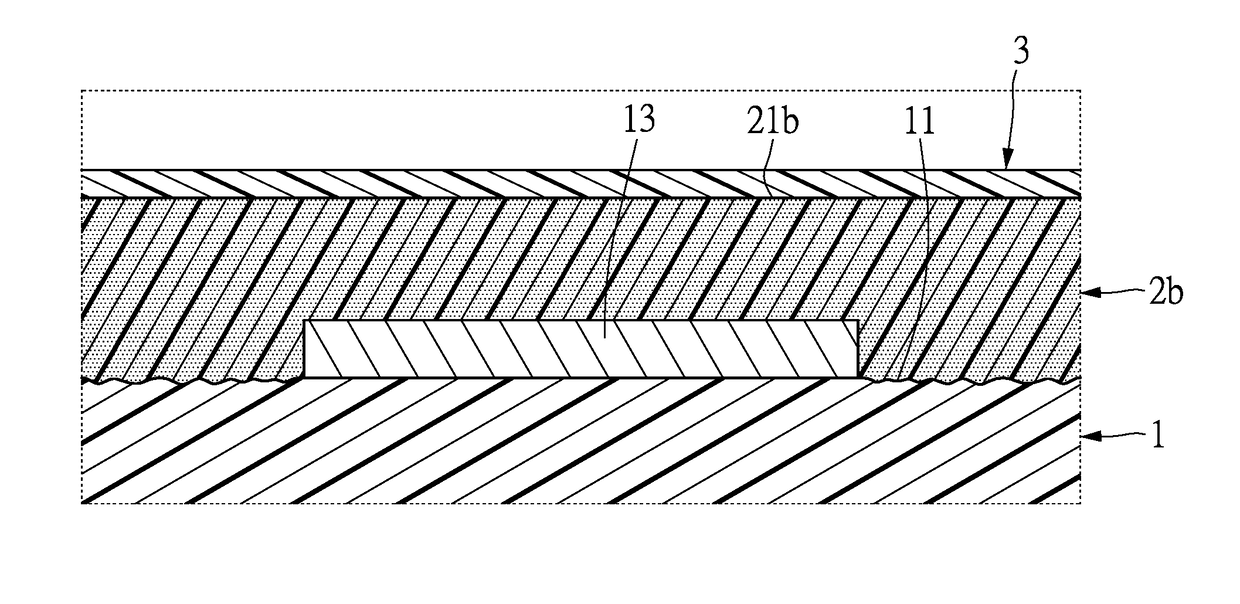

Circuit board structure and method for manufacturing the same

InactiveUS20170231100A1Efficient solutionReduce manufacturing costLaminating printed circuit boardsPrinted circuit aspectsBoard structureElectrical and Electronics engineering

A circuit board structure includes a circuit board and an adhesive layer. The circuit board has a first board surface and an opposite second board surface, and the first board surface defines a predetermined portion. The circuit board has a conductive circuit disposed on the first board surface and at least partially arranged on the predetermined portion. The adhesive layer is seamlessly formed on the predetermined portion of the first board surface of the circuit board, and the conductive circuit arranged on the predetermined portion is seamlessly covered by the adhesive layer. A surface of the adhesive layer arranged away from the circuit board is a planar bonding surface.

Owner:ICHIA TECH

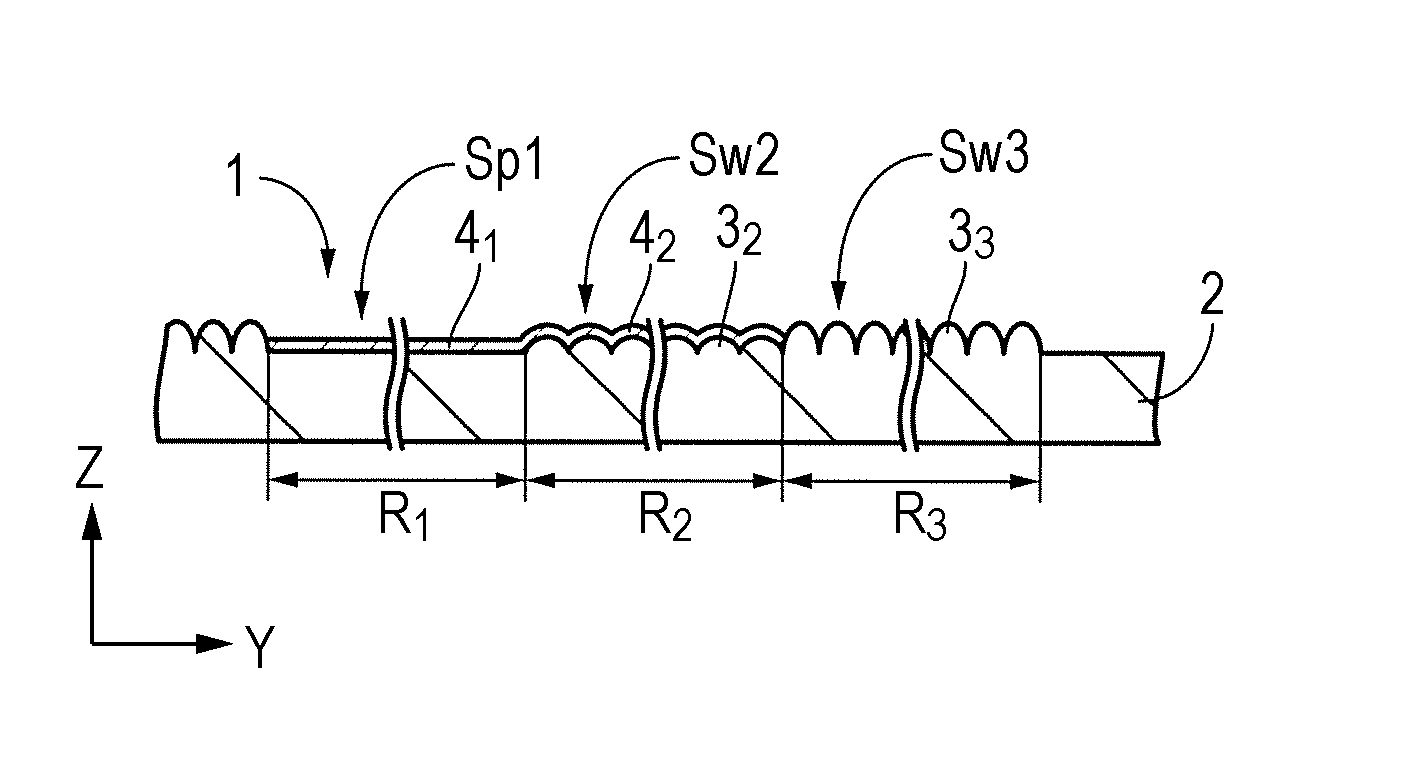

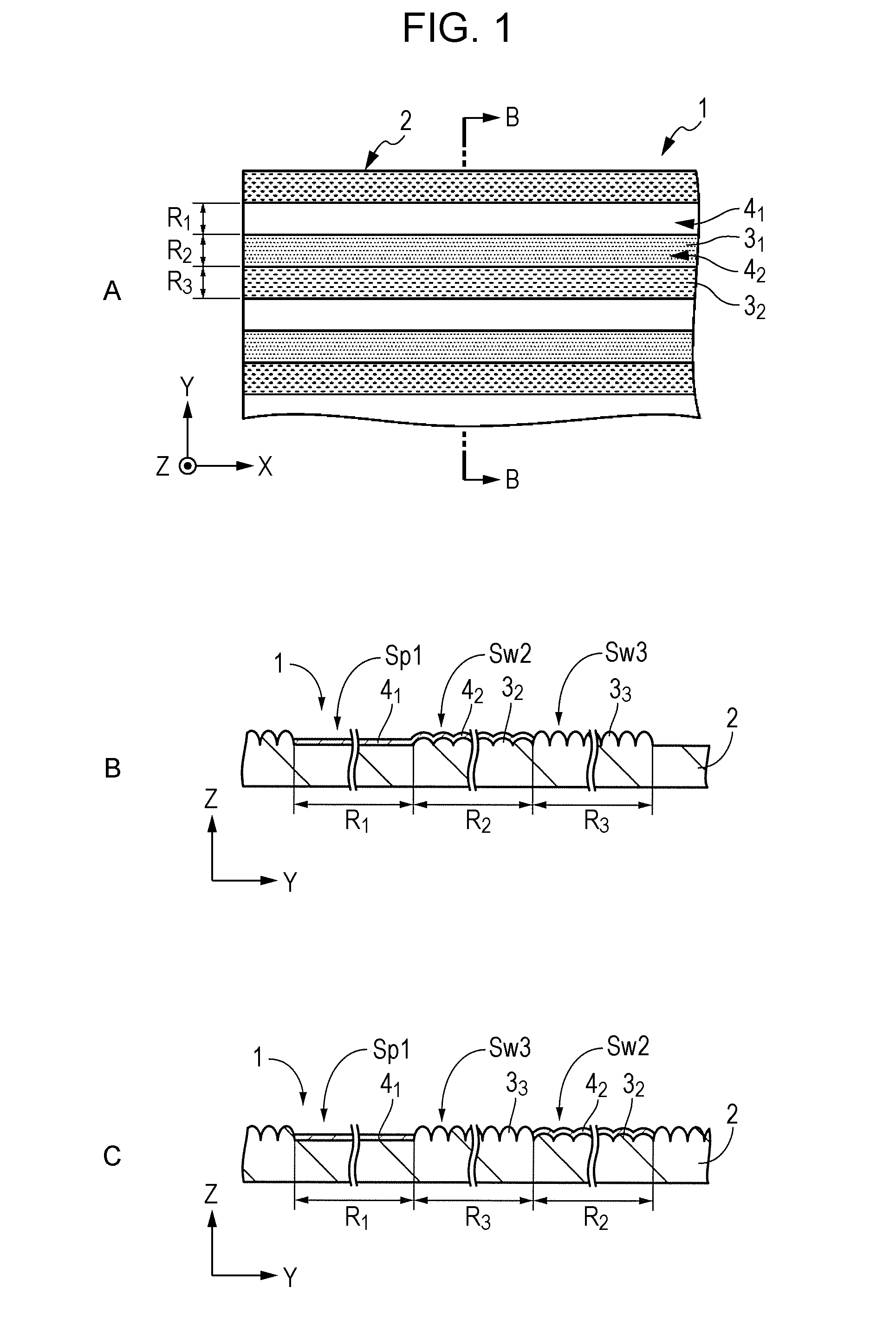

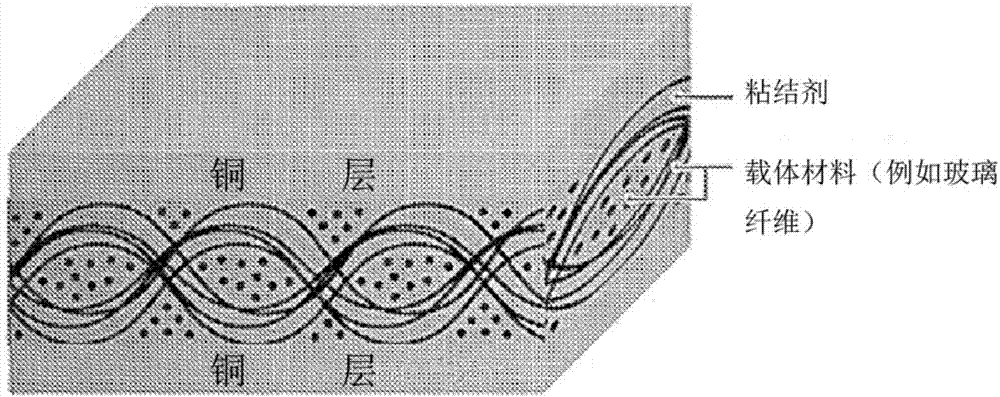

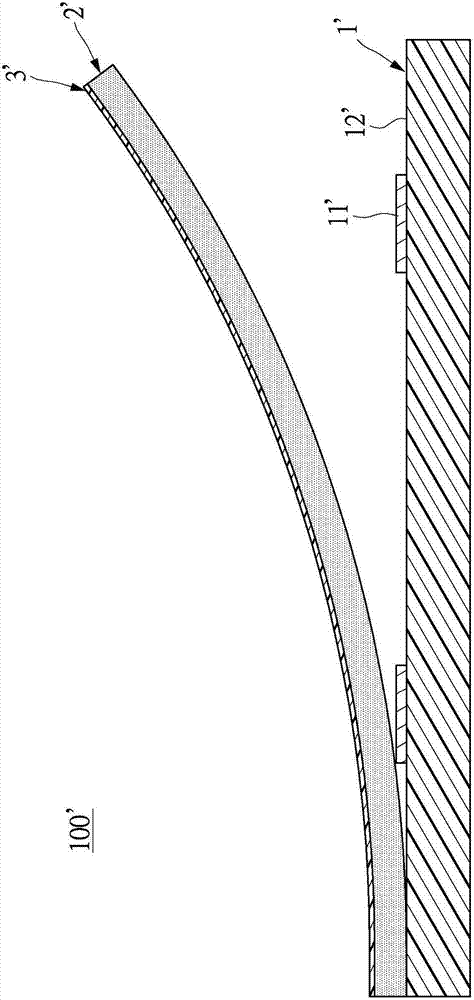

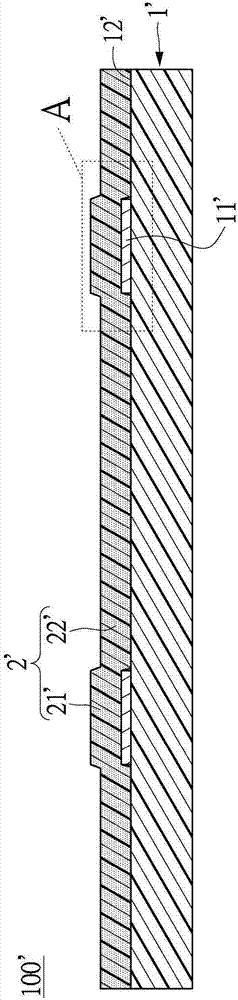

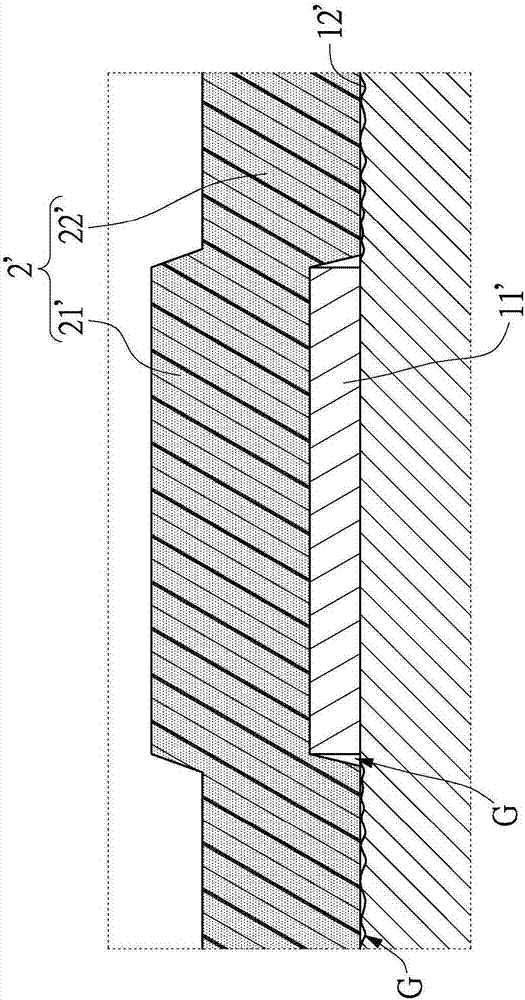

Conductive element and method of manufacturing the same, wiring element, and master copy

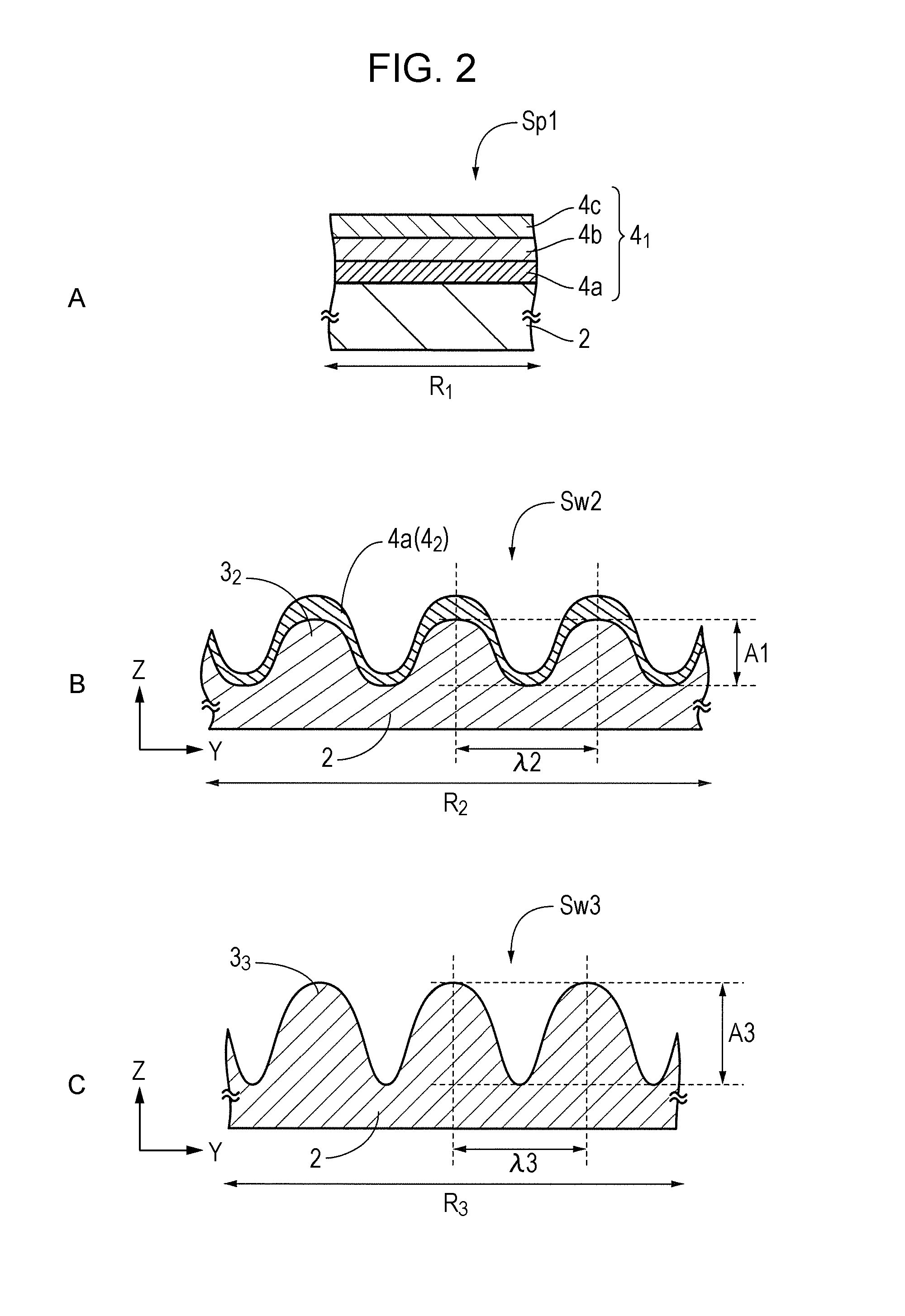

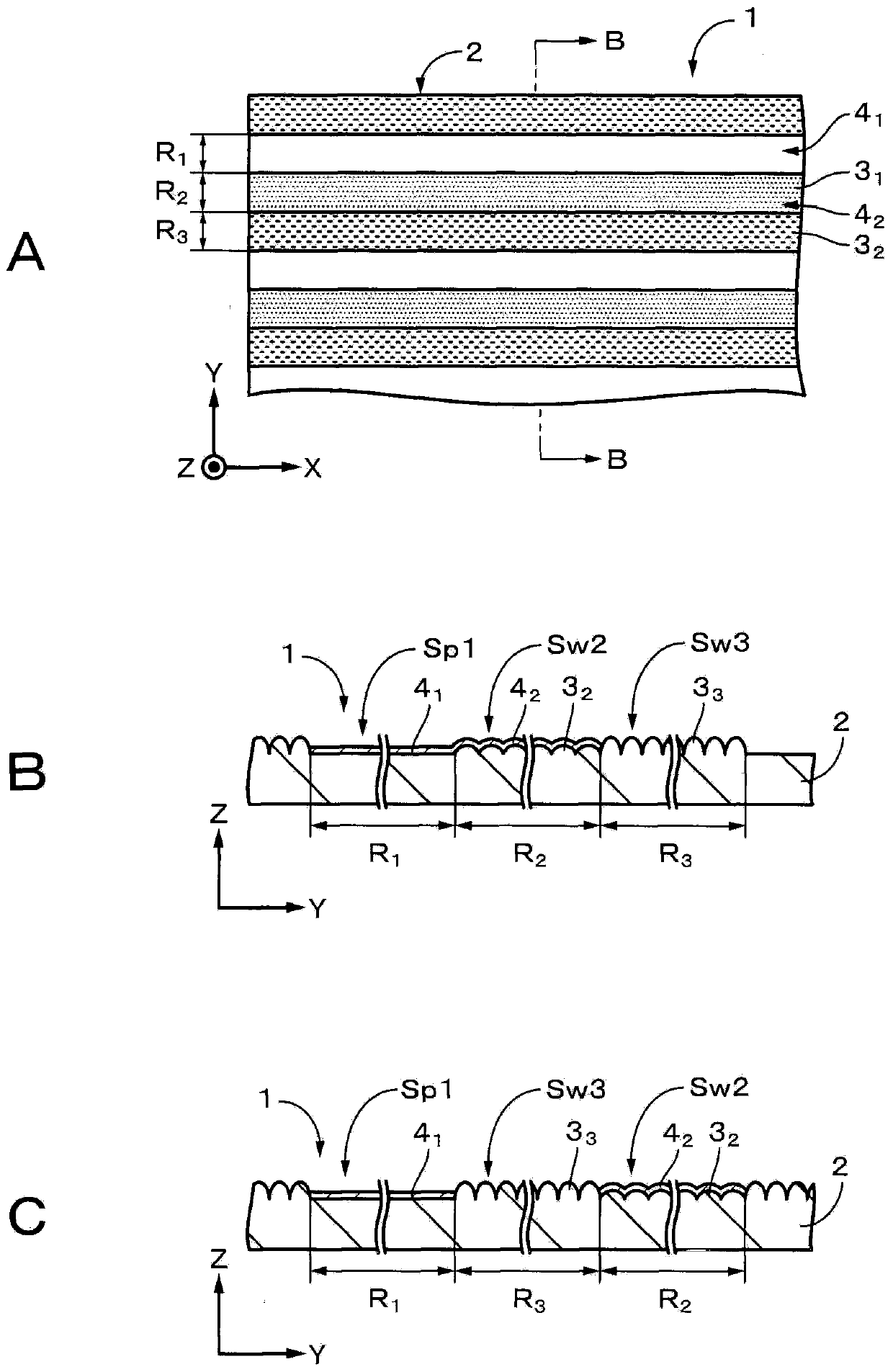

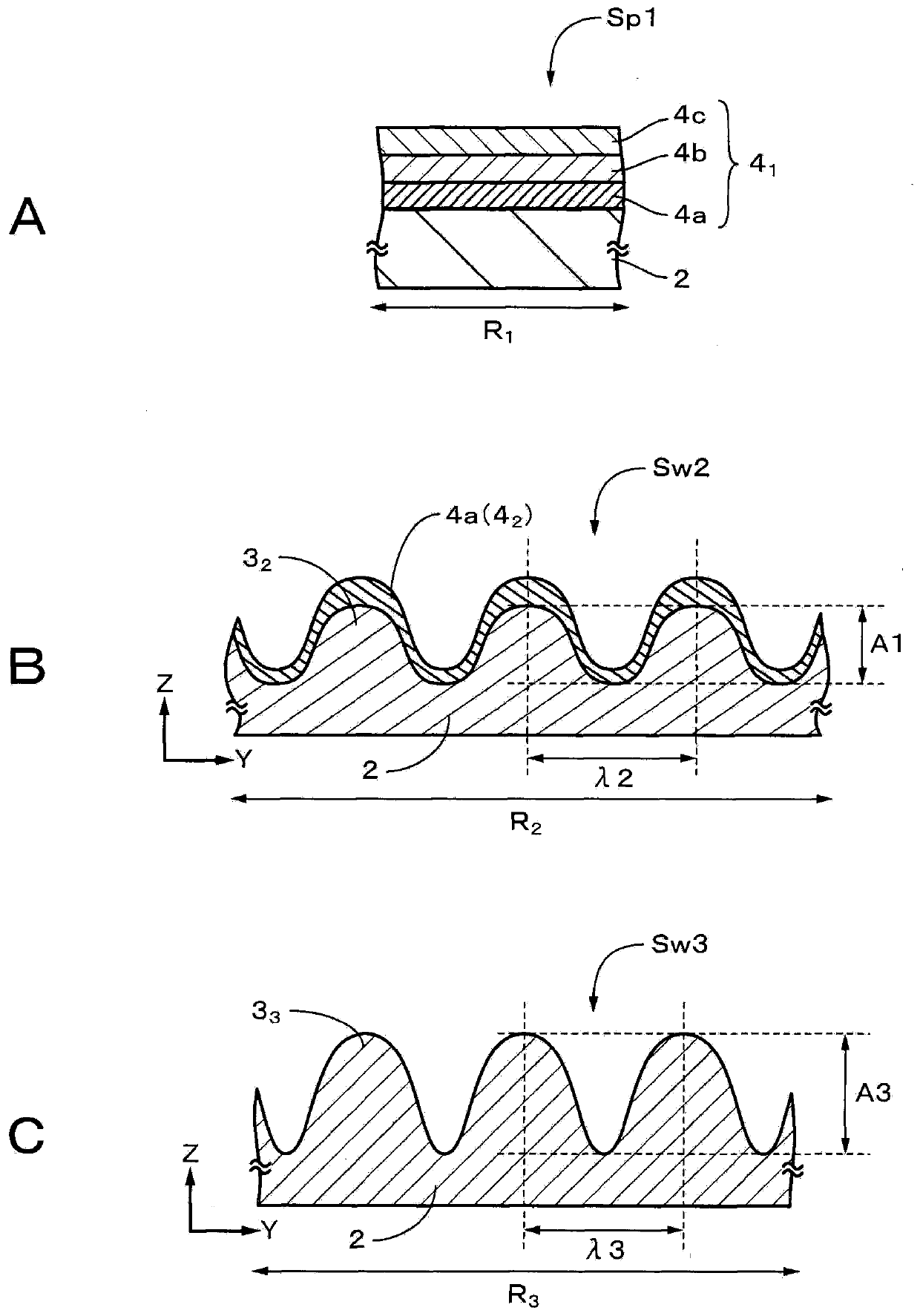

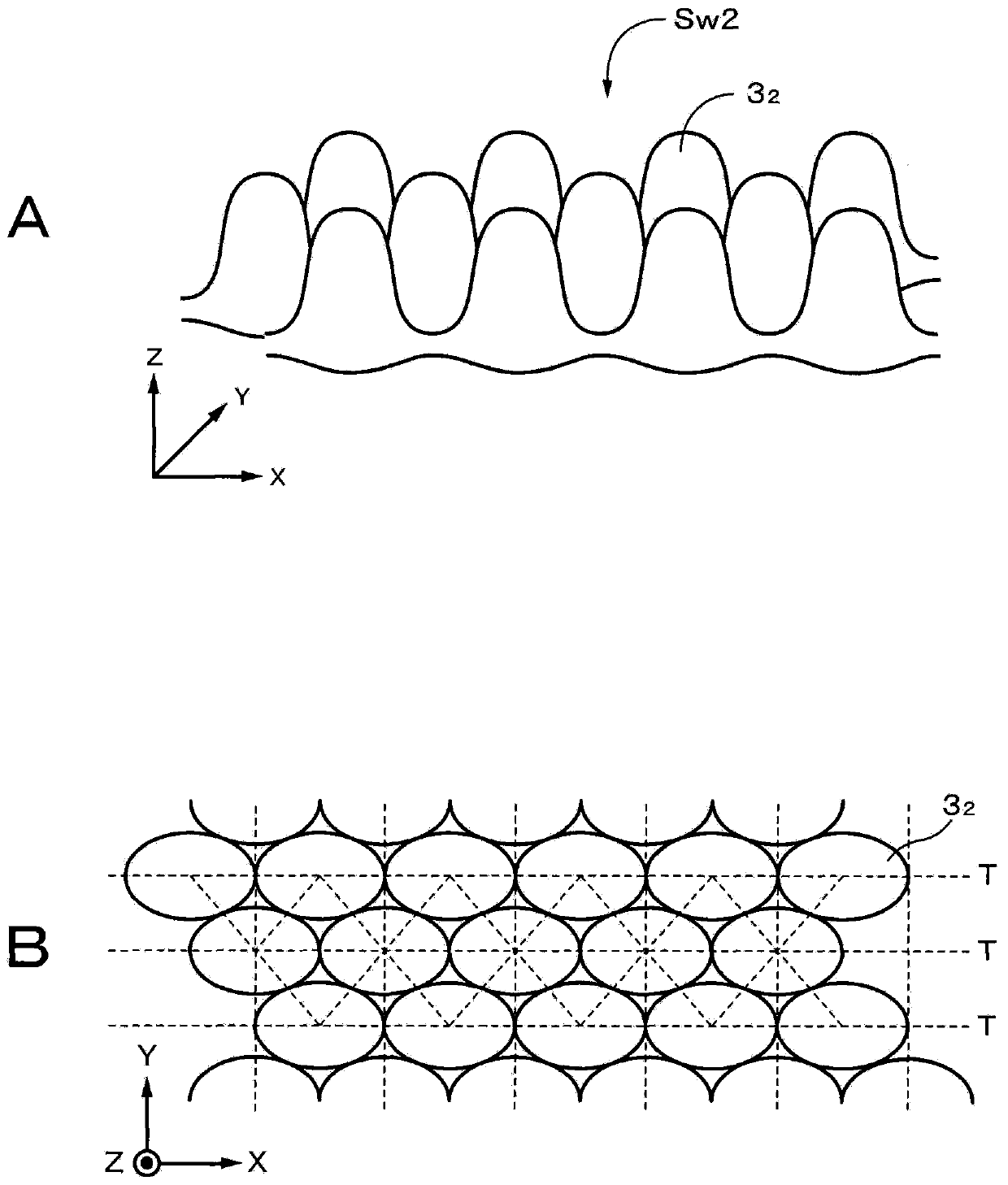

ActiveUS20150027759A1Improve throughputElectroluminescent light sourcesPrinted circuit aspectsThird waveEngineering

A conductive element includes: a substrate having a first wavy surface, a second wavy surface, and a third wavy surface; a first layer provided on the first wavy surface; and a second layer formed on the second wavy surface. The first and second layers form a conductive pattern portion. The first, second, and third wavy surfaces satisfy the following relationship:0≦(Am1 / λm1)<(Am2 / λm2)<(Am3 / λm3)≦1.8(where Am1 is an average width of vibrations of the first wavy surface, Am2 is an average width of vibrations of the second wavy surface, Am3 is an average width of vibrations of the third wavy surface, λm1 is an average wavelength of the first wavy surface, λm2 is an average wavelength of the second wavy surface, and λm3 is an average wavelength of the third wavy surface.)

Owner:SONY CORP

Conductive-pattern formation method and composition for forming conductive pattern via light exposure or microwave heating

ActiveCN103947304AImprove conductivityPrinted circuit aspectsConductive materialMicrowaveCopper oxide

Owner:RESONAC CORPORATION

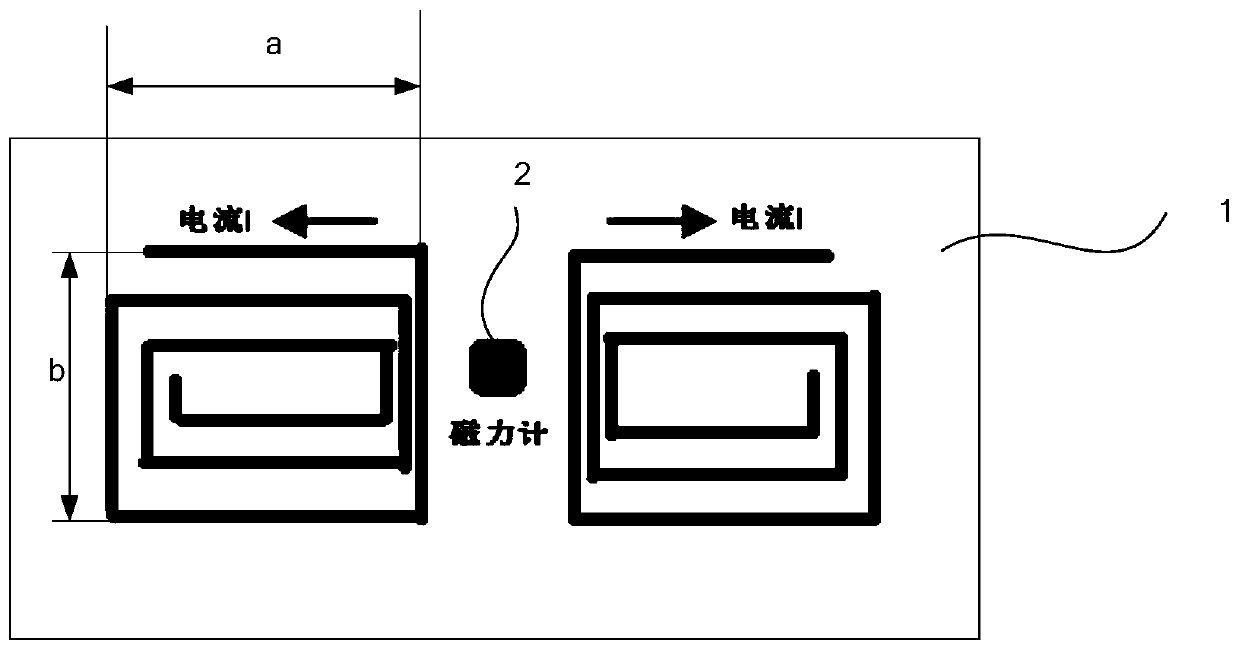

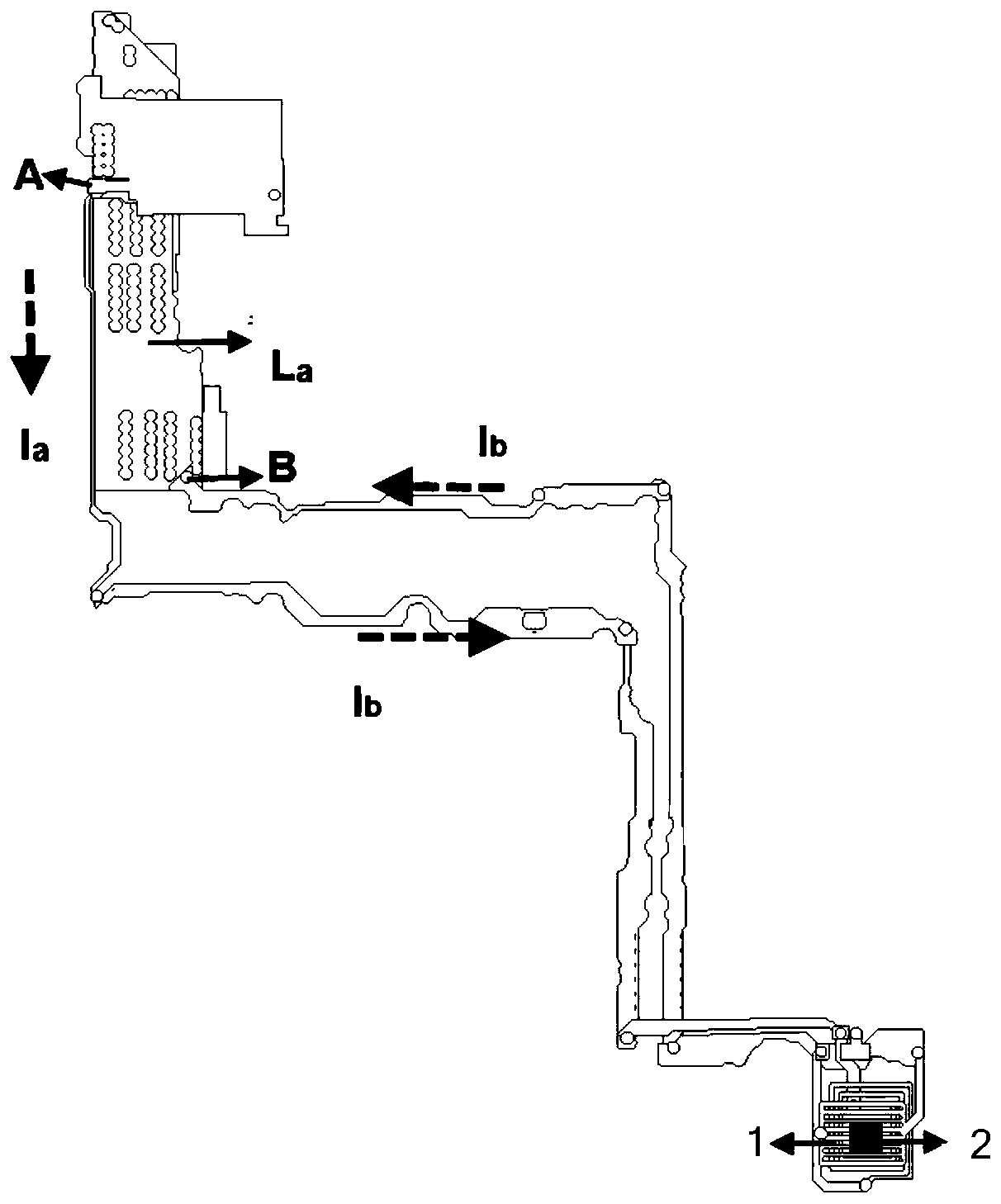

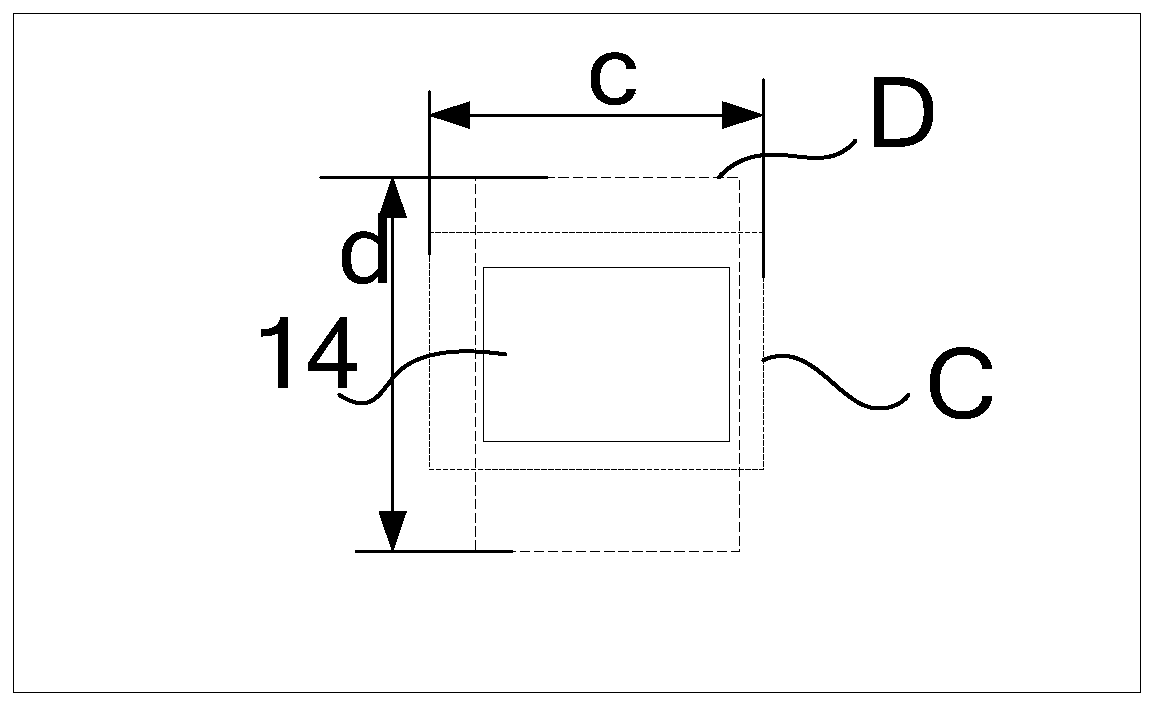

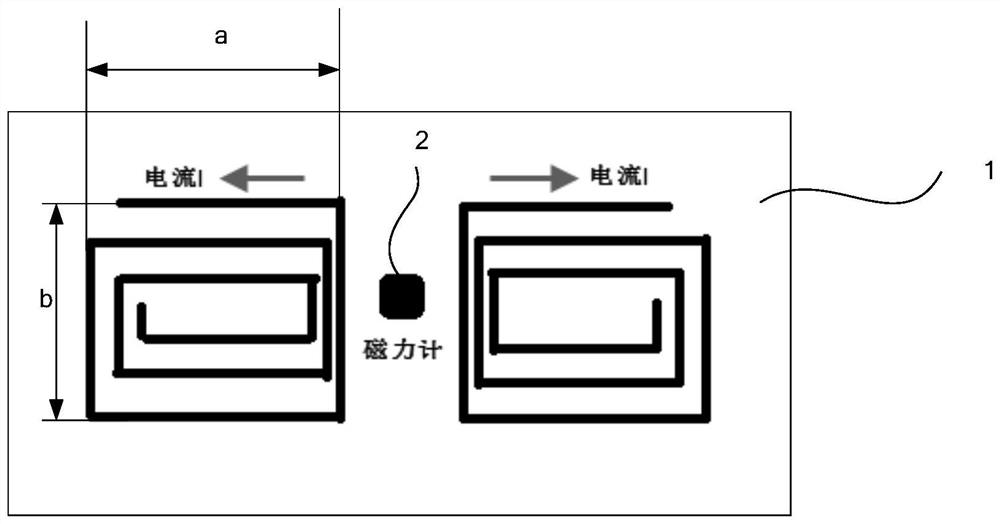

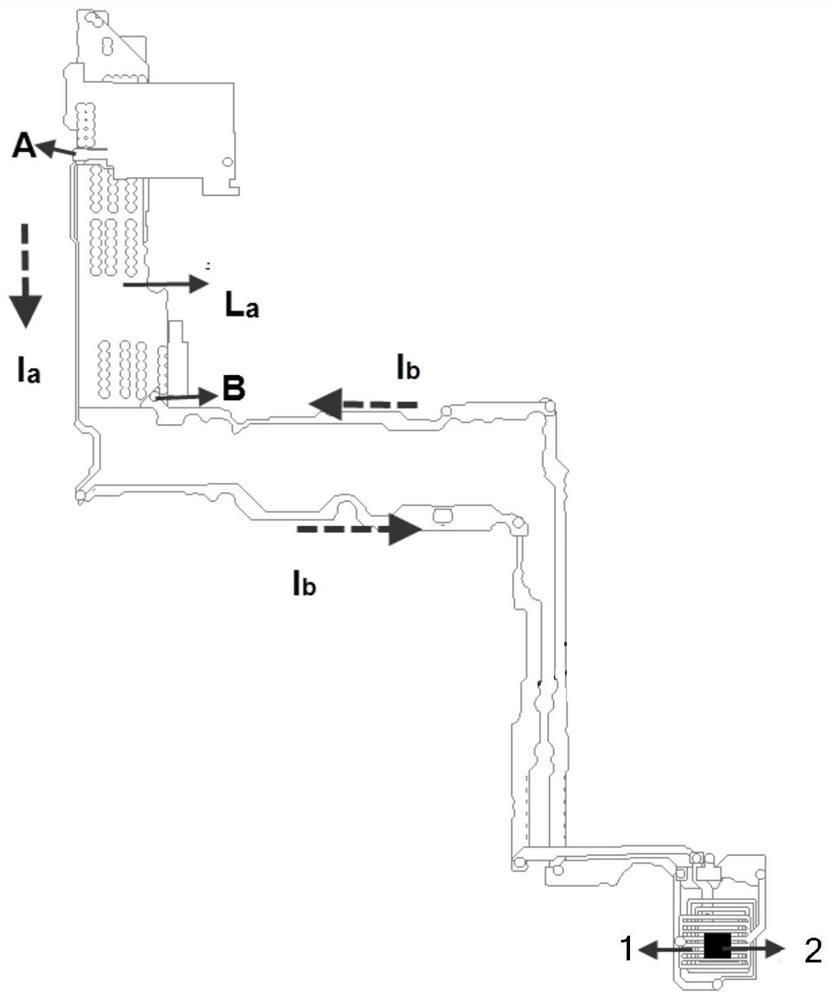

Anti-interference circuit board and terminal

ActiveCN111586960AMagnetic field offset compensationPrinted circuit aspectsVertical projectionInterference resistance

The invention provides an anti-interference circuit board and a terminal. The circuit board specifically comprises a substrate which is provided with a first surface, and the first surface is providedwith a first region for placing a magnetometer; the substrate is internally provided with a plurality of circuit layers, and the plurality of circuit layers are arranged in a stacked manner, for example, the substrate is at least internally provided with a first functional circuit used for generating a magnetic field generated in a first direction and a second functional circuit used for generating a magnetic field generated in a second direction which are stacked; when the positions of the first functional circuit and the second functional circuit are specifically set, the first region is located in the vertical projection of the first functional circuit and the second functional circuit on the first surface. What can be seen from the description is that the first functional circuit andthe second functional circuit are arranged to compensate the interference of the magnetometer in the first region, and the first functional circuit and the second functional circuit are located belowthe magnetometer during arrangement, so that the occupied surface area of the anti-interference circuit board is reduced.

Owner:HUAWEI TECH CO LTD

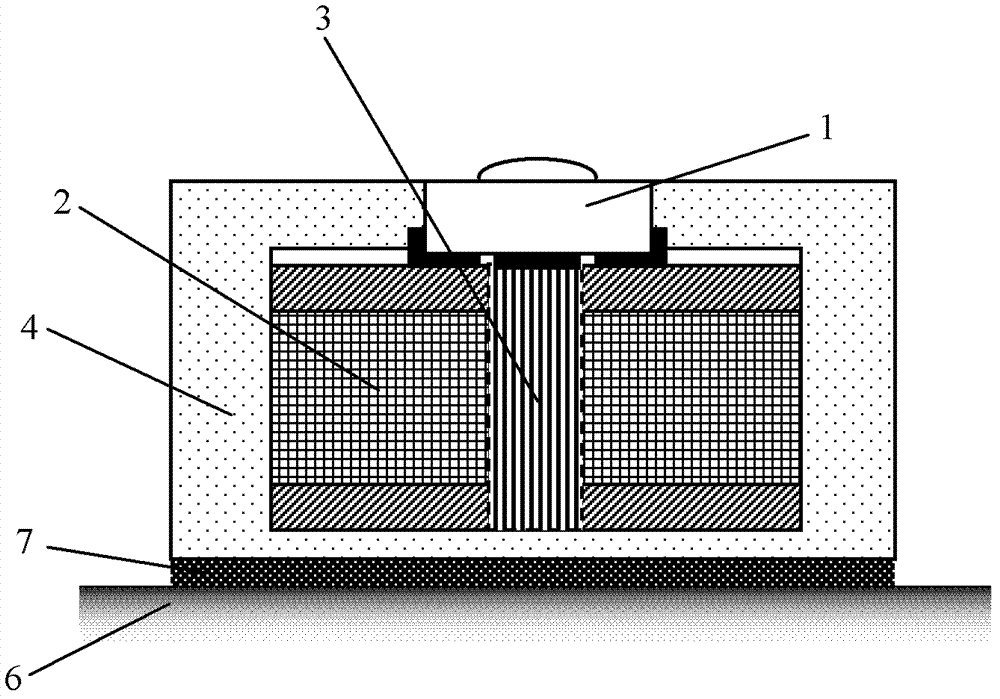

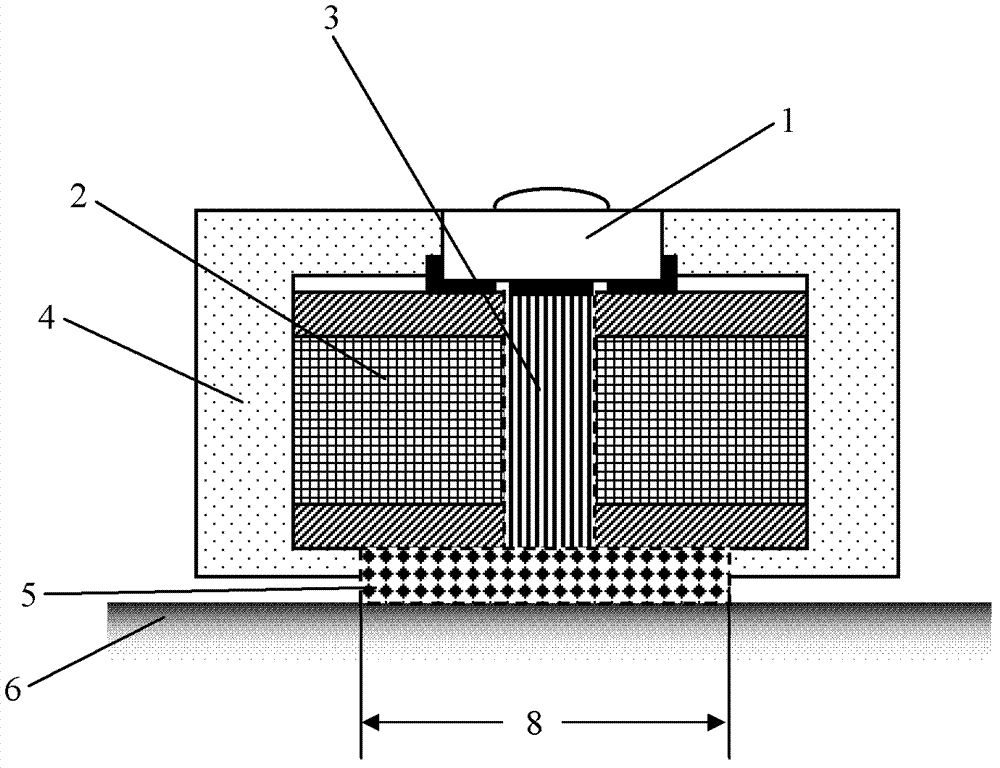

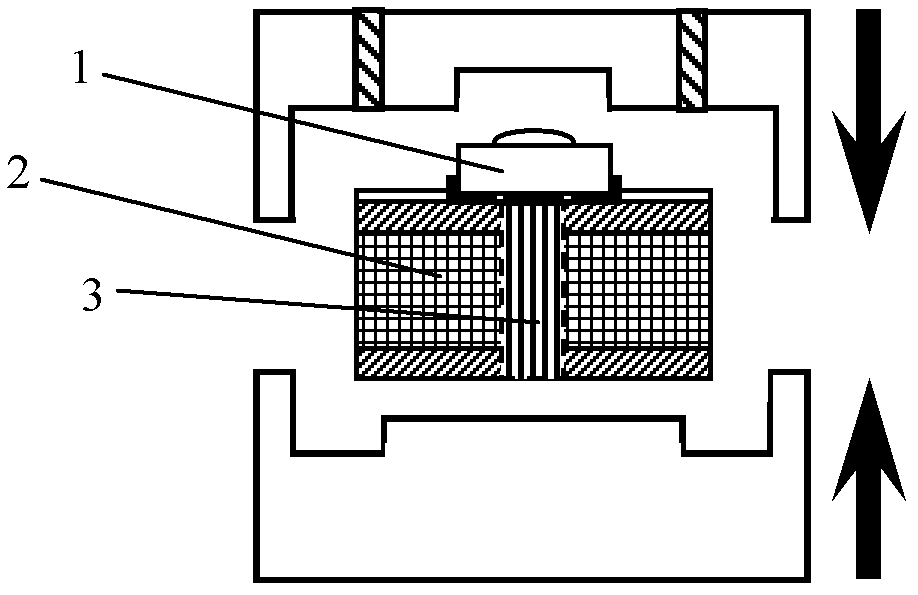

Electronic module, light emitting device and manufacture method of electronic module

InactiveCN102956787APrinted circuit aspectsTreatment using electric/magnetic/electromagnetic fieldsComputer moduleLight emitting device

The invention relates to an electronic module used for being installed to a mounting surface (6). The electronic module comprises a circuit board (2) disposed on a heat source (1) and envelope material (4) which packages the circuit board (2) at least from the other side facing to the heat source (1). The circuit board (2) is provided with a through heat hole (3). The heat source (1) thermally contacts with the heat hole (3). At least part of the other side of the circuit board (2), corresponding to the heat hole (3), is provided with a cavity (8), and the cavity (8) is filled with heat conduction material (5) which is thermally conductively connected to the mounting surface. In addition, the invention further relates to a light emitting device, and a manufacture method of the electronic module. The electronic module is simple in structure and low in manufacture cost. The envelope material of the module is modified, so that the electronic module is low in thermal resistance and fine in stability.

Owner:OSRAM GMBH

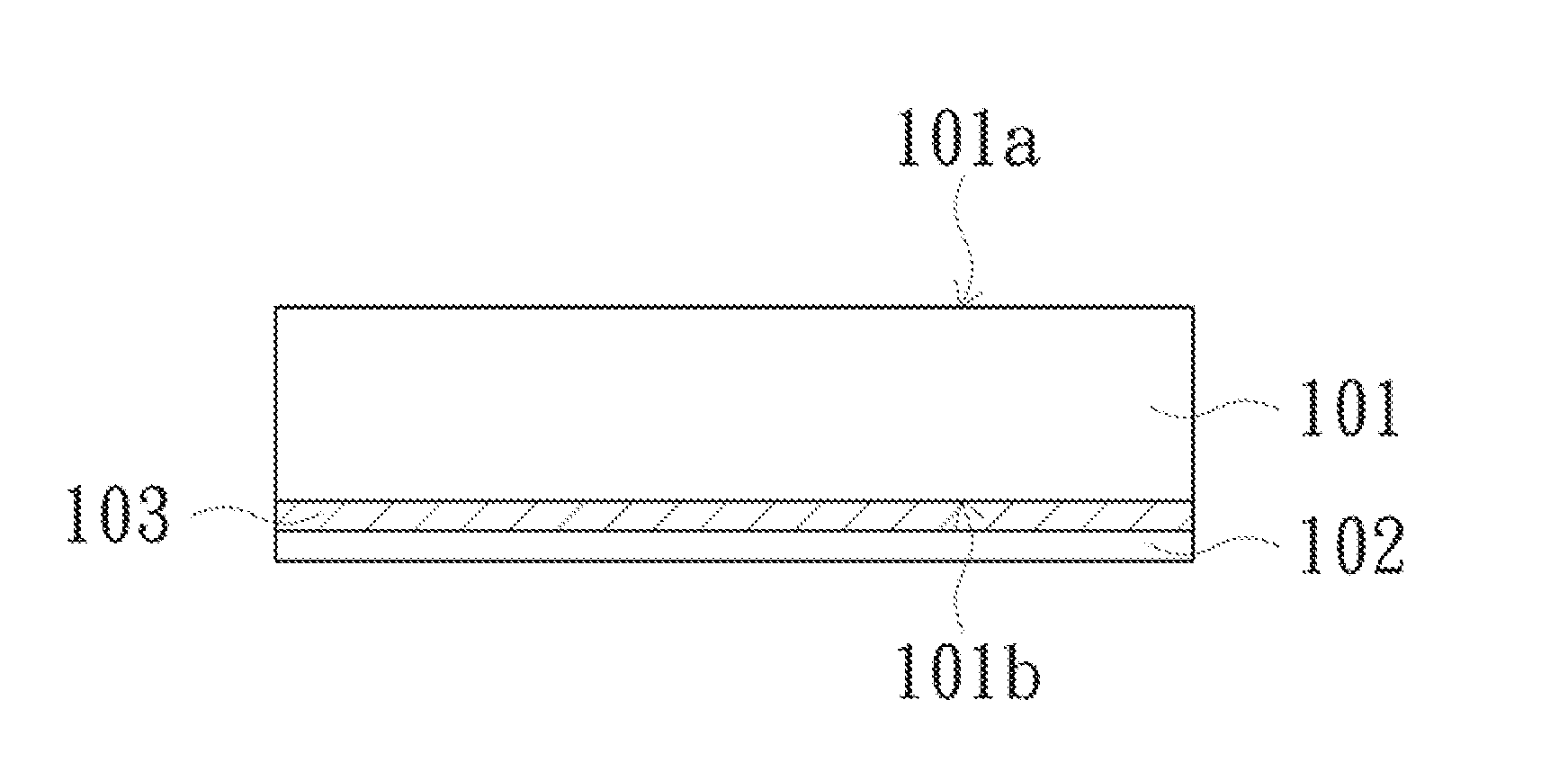

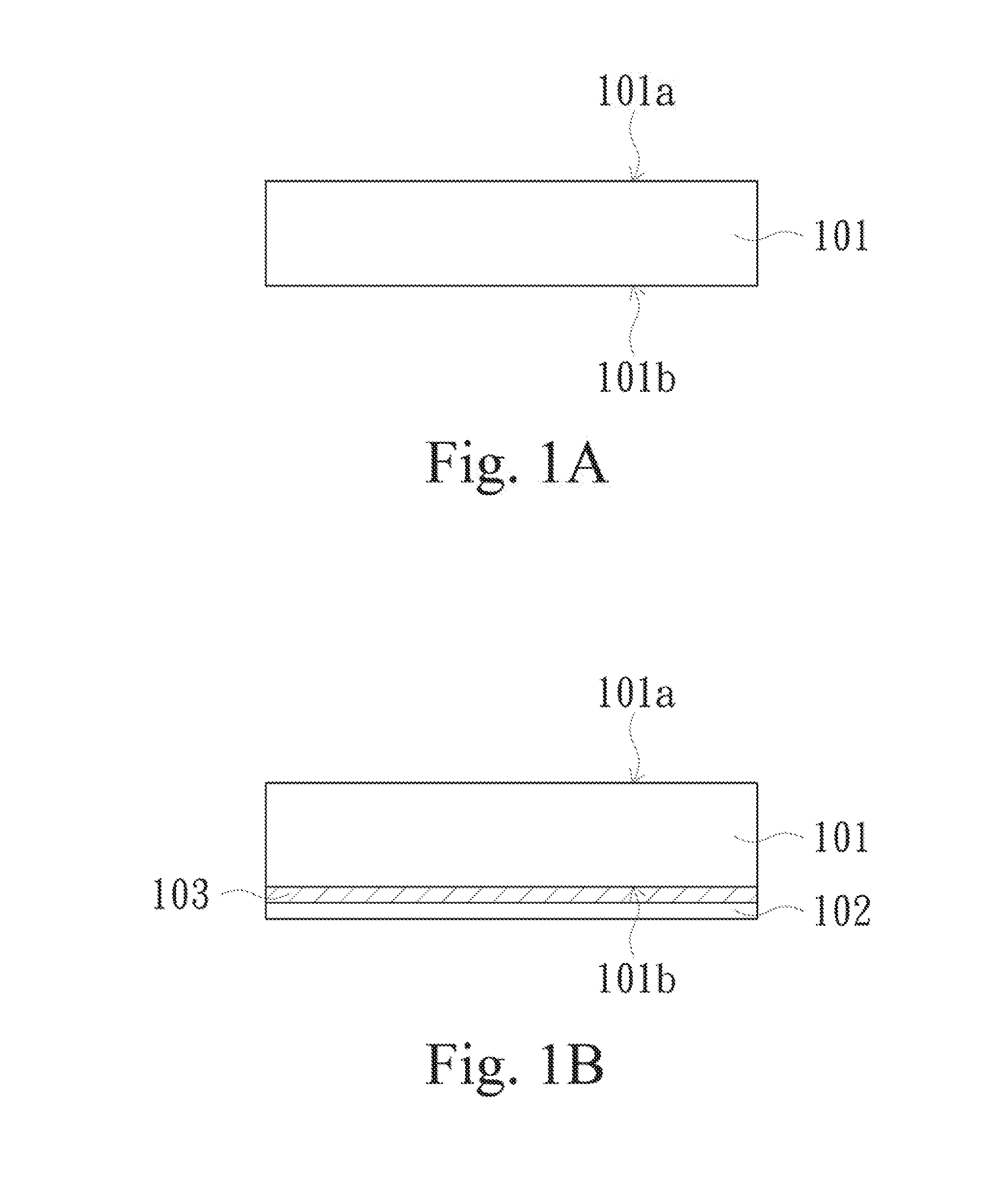

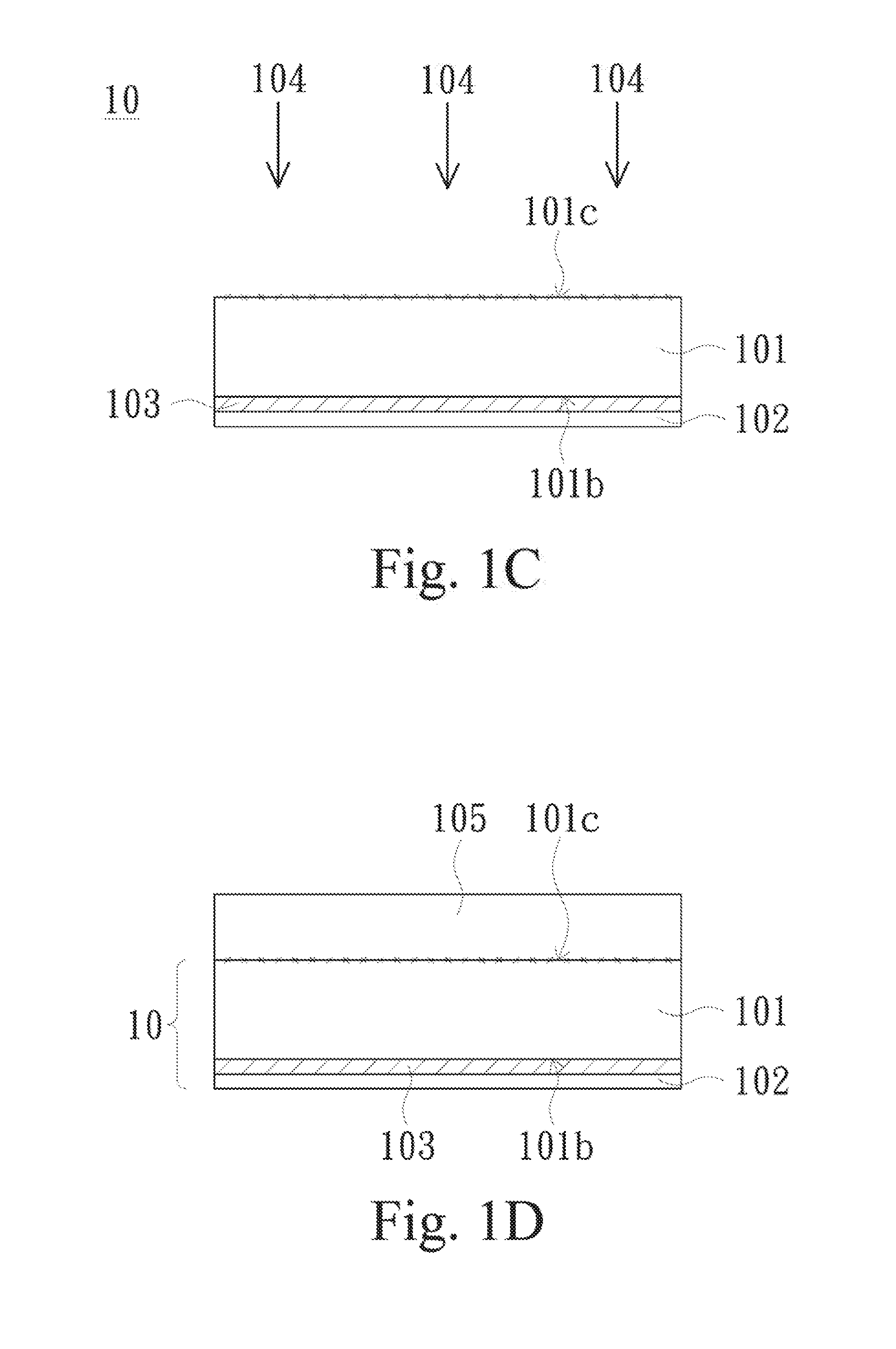

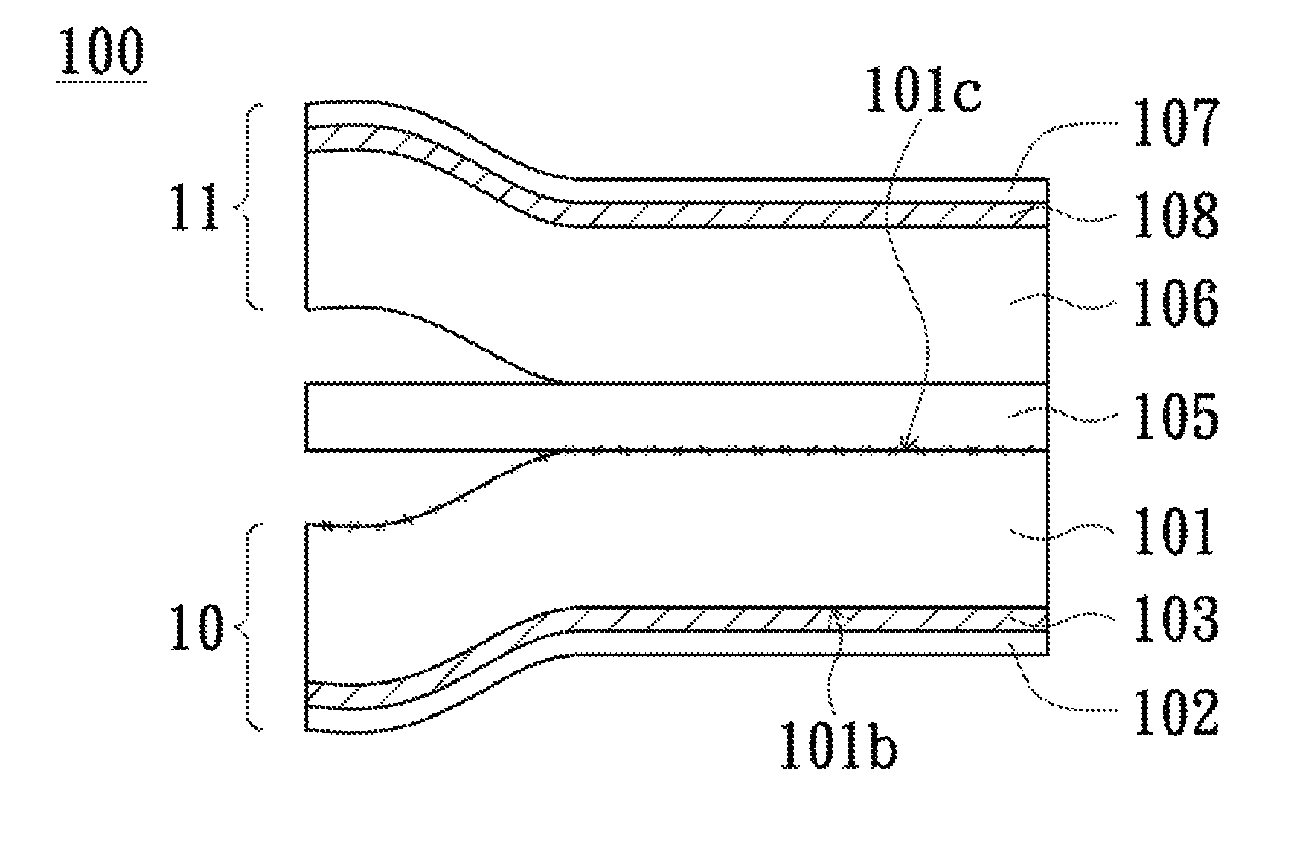

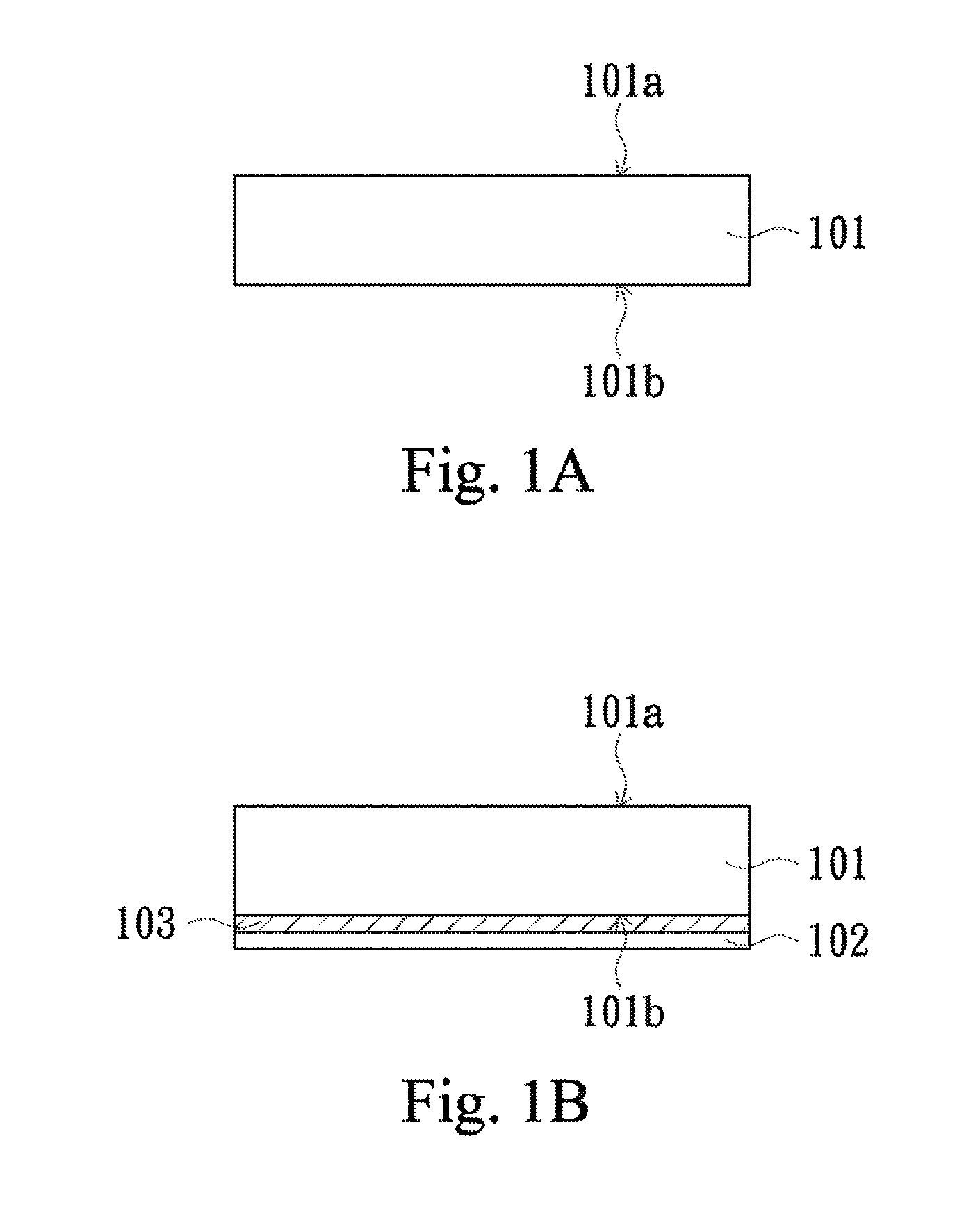

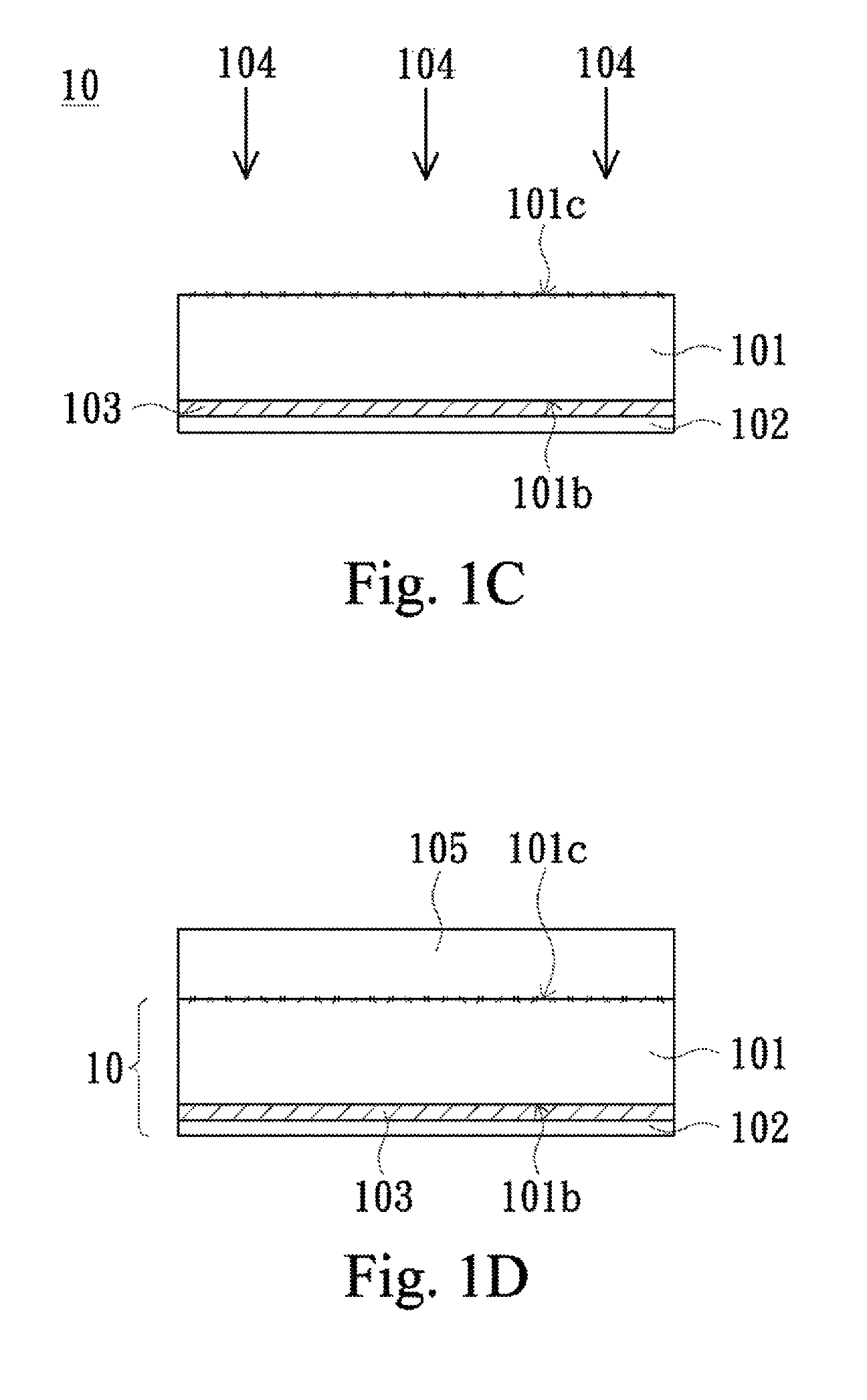

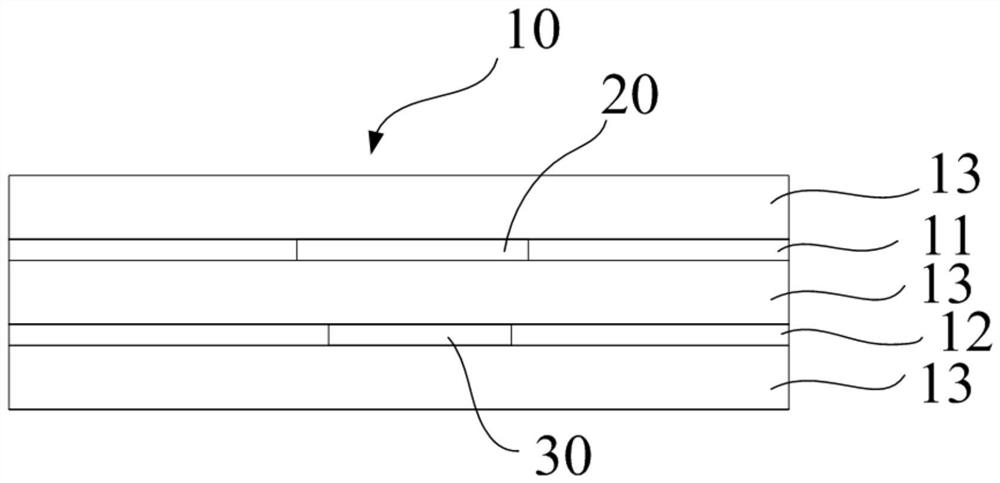

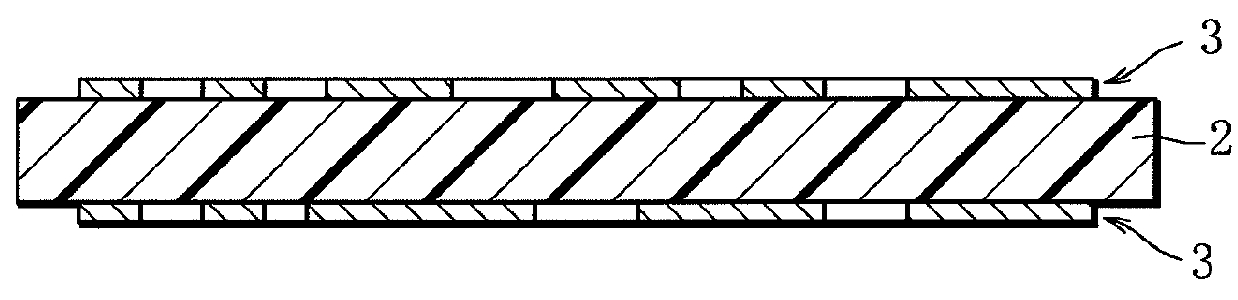

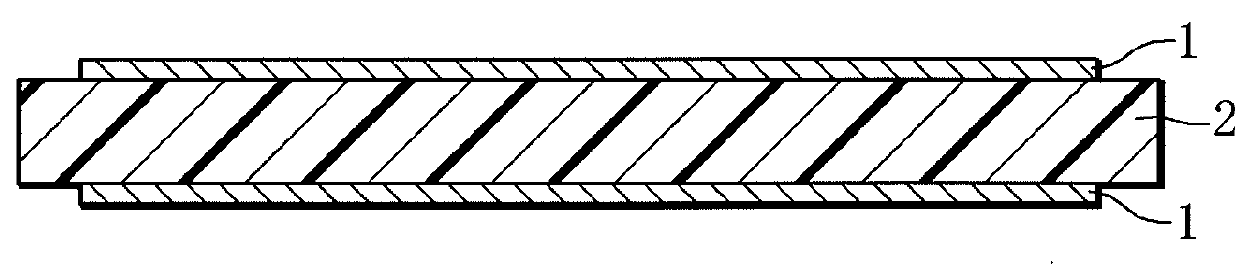

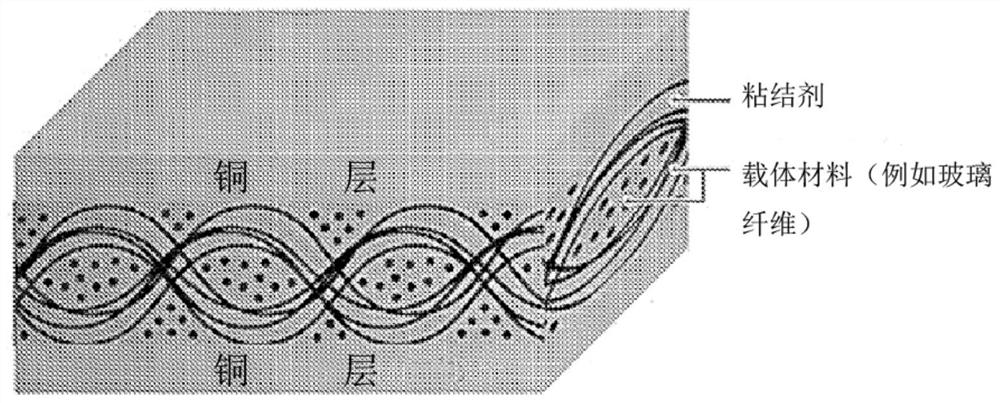

Metal substrate and method of manufacturing the same

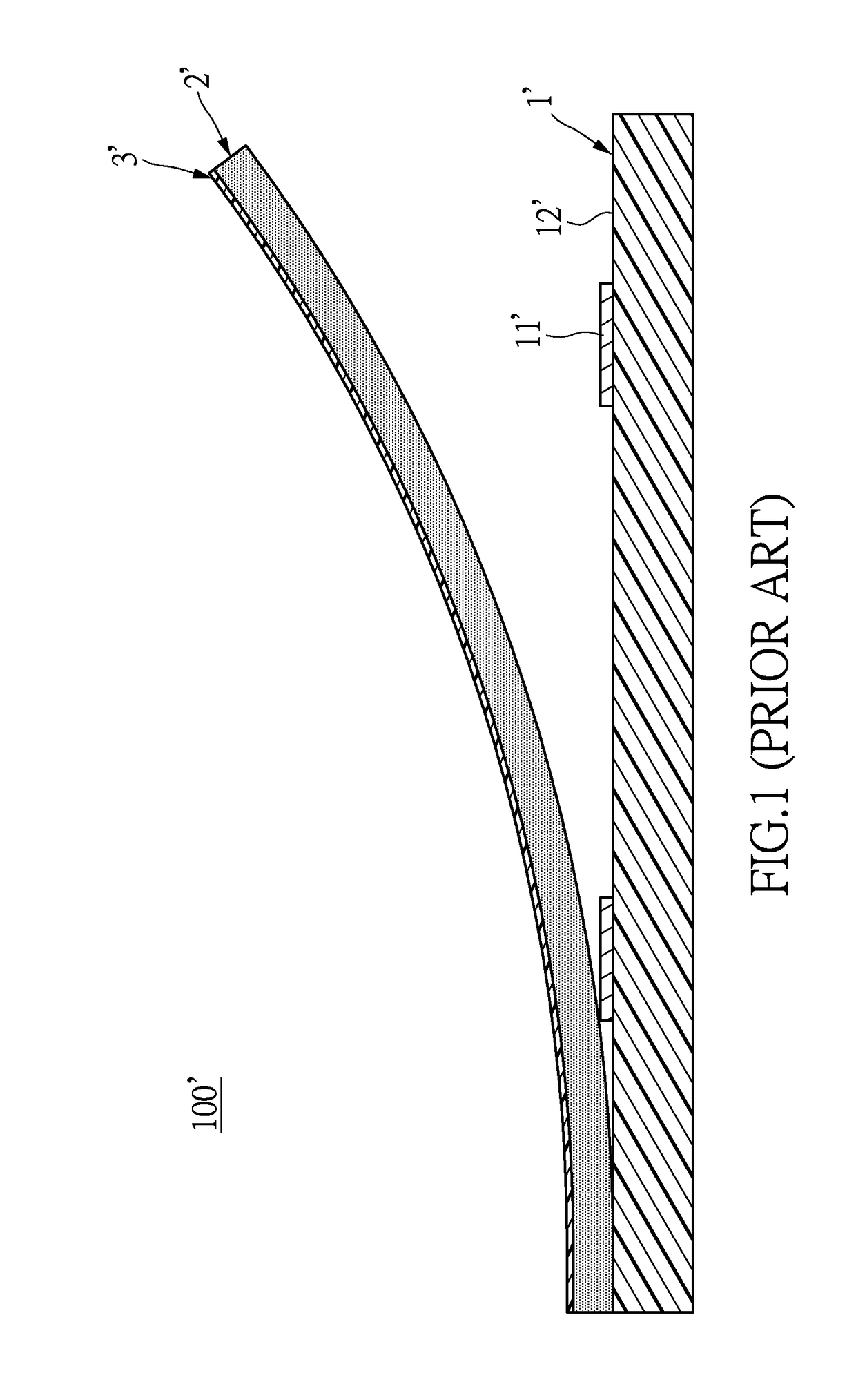

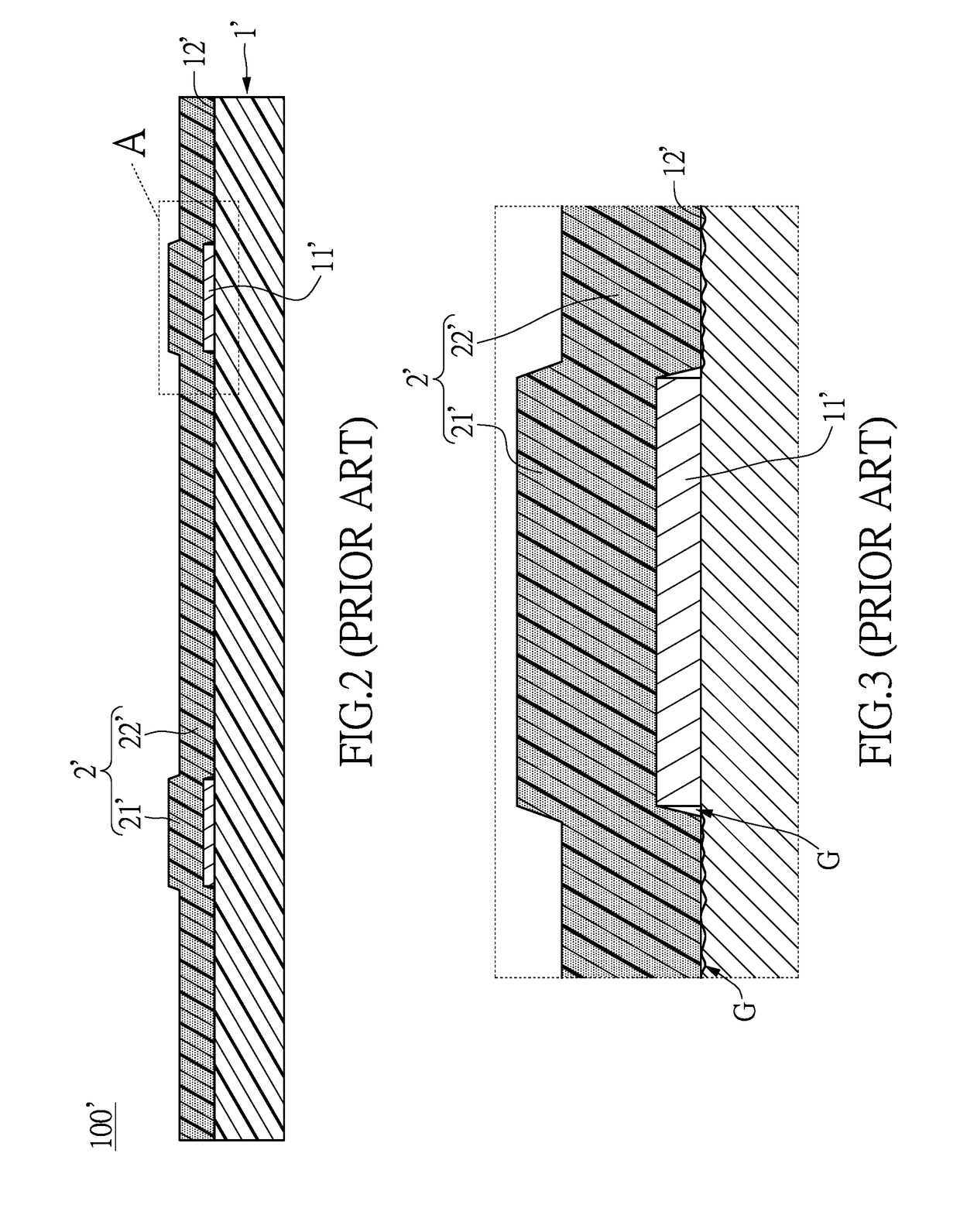

ActiveUS20160316568A1Improve structural strengthIncrease productionPrinted circuit secondary treatmentAdhesivesSurface roughnessOptoelectronics

A metal substrate includes a first insulating substrate, a second insulating substrate, a first metal layer, a second metal layer and a release layer. The first insulating substrate has a first modified surface and a second surface opposite to the first modified surface. The first metal layer faces the second surface. The release layer is bonded on the first modified surface. The second insulating substrate is bonded on a side of the release layer, such that the release layer is between the first modified surface and the second insulating substrate. The second metal layer is disposed on a side of the second insulating substrate, such that the second insulating substrate is between the release layer and the second metal layer. An original surface roughness of the first modified surface has a variation substantially less than 10% after the first modified surface is released from the release layer.

Owner:AZOTEK

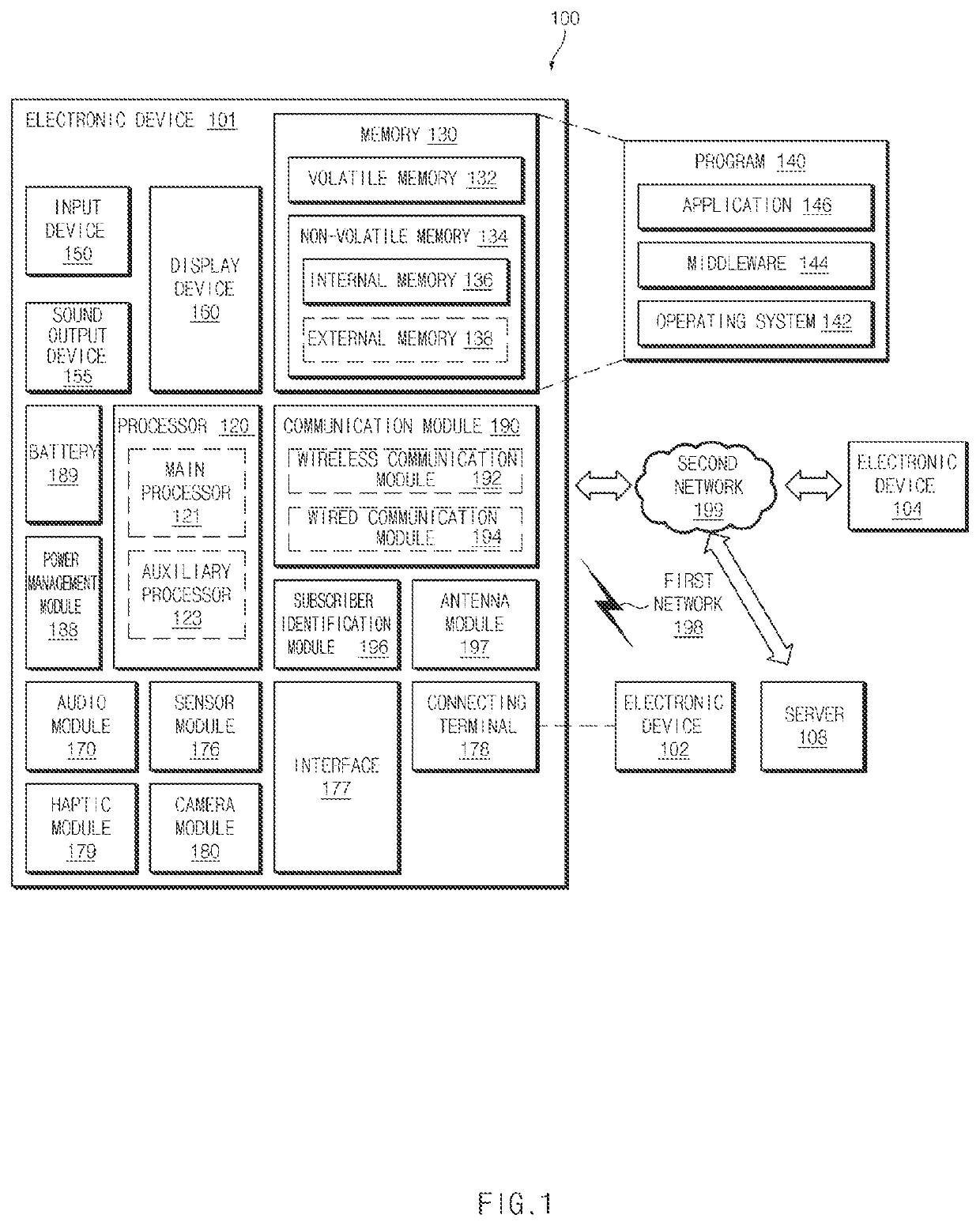

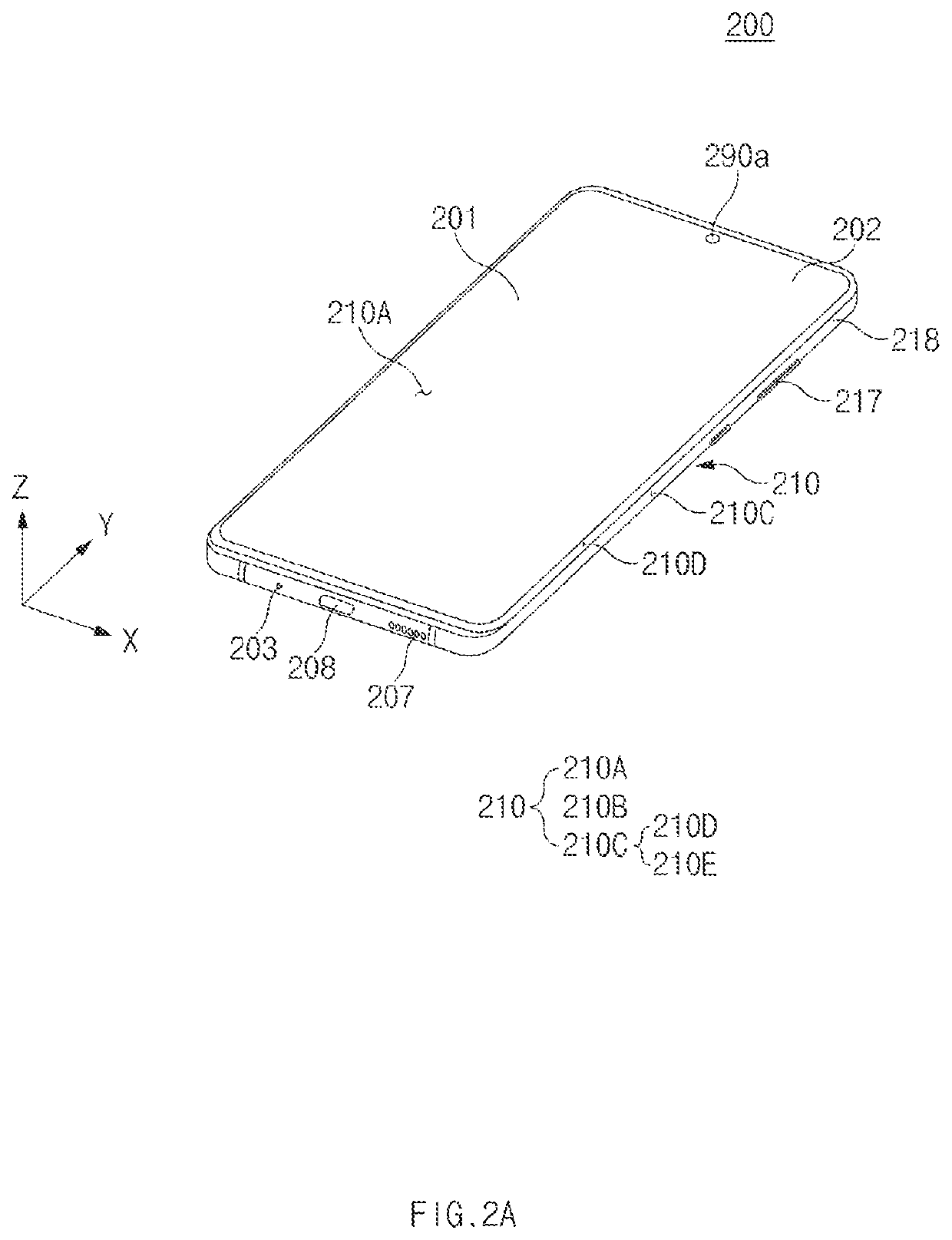

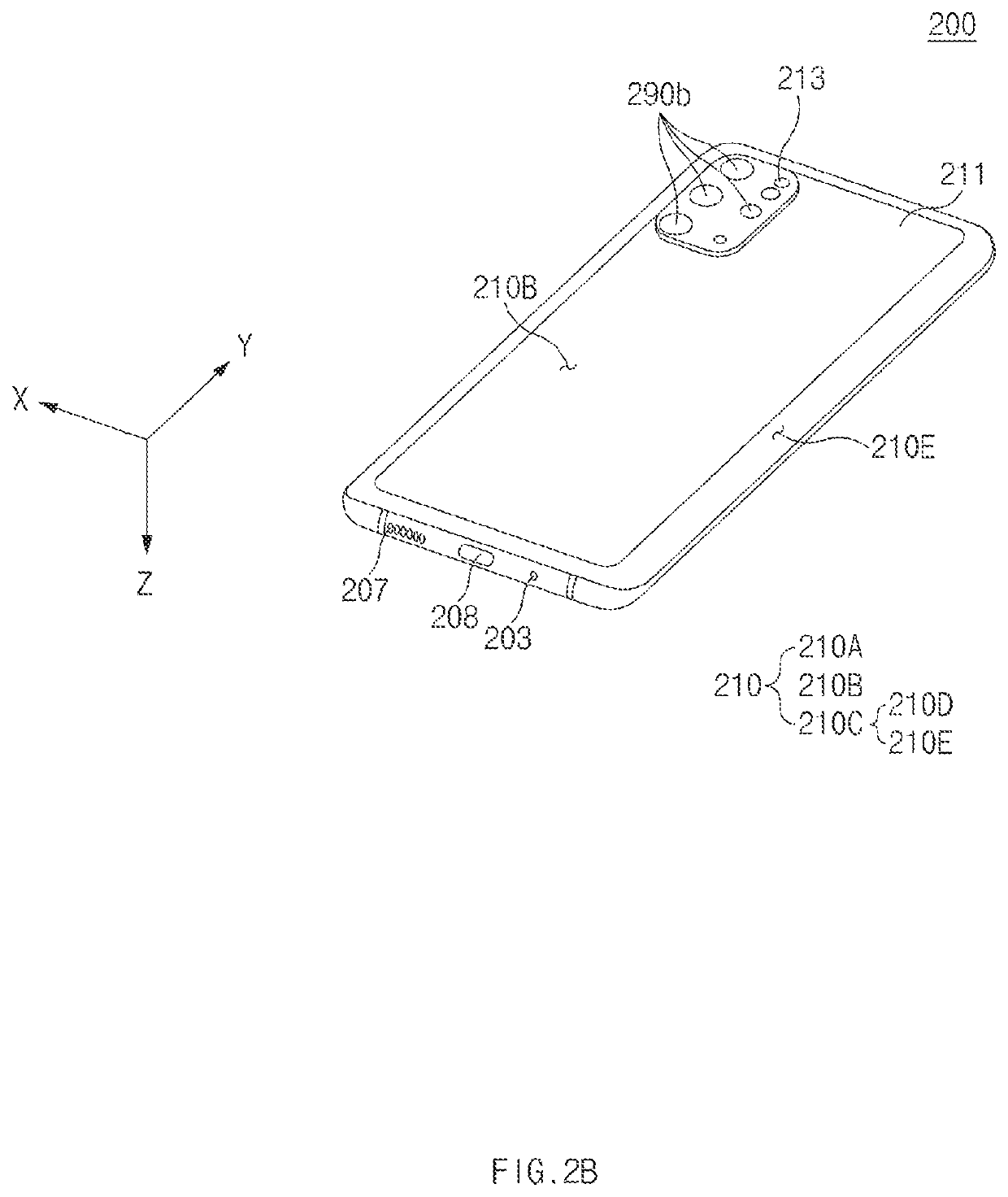

PCB structure and electronic device including the same

ActiveUS11483935B2Degree of improvementIncrease profitPrinted circuit assemblingCircuit optical detailsEngineeringConductive materials

An electronic device includes: a housing and a printed circuit board (PCB) structure disposed in the housing. The PCB structure includes a circuit board including an opening area formed through a first surface of the circuit board and a second surface of the circuit board opposite the first surface and a conductive pattern formed in a peripheral area around the opening area, a plate disposed on the second surface of the circuit board covering the opening area, an electronic element disposed on the plate and electrically connected with the circuit board, a resin portion disposed between the plate and the circuit board and extending from the conductive pattern, the resin portion including a conductive material, and a solder portion formed between the resin portion and the plate.

Owner:SAMSUNG ELECTRONICS CO LTD

Peelable metal substrate having modified surface and method of manufacturing the same

ActiveUS9414485B2Improve structural strengthIncrease productionPrinted circuit secondary treatmentAdhesivesSurface roughnessOptoelectronics

A metal substrate includes a first insulating substrate, a second insulating substrate, a first metal layer, a second metal layer and a release layer. The first insulating substrate has a first modified surface and a second surface opposite to the first modified surface. The first metal layer faces the second surface. The release layer is bonded on the first modified surface. The second insulating substrate is bonded on a side of the release layer, such that the release layer is between the first modified surface and the second insulating substrate. The second metal layer is disposed on a side of the second insulating substrate, such that the second insulating substrate is between the release layer and the second metal layer. An original surface roughness of the first modified surface has a variation substantially less than 10% after the first modified surface is released from the release layer.

Owner:AZOTEK

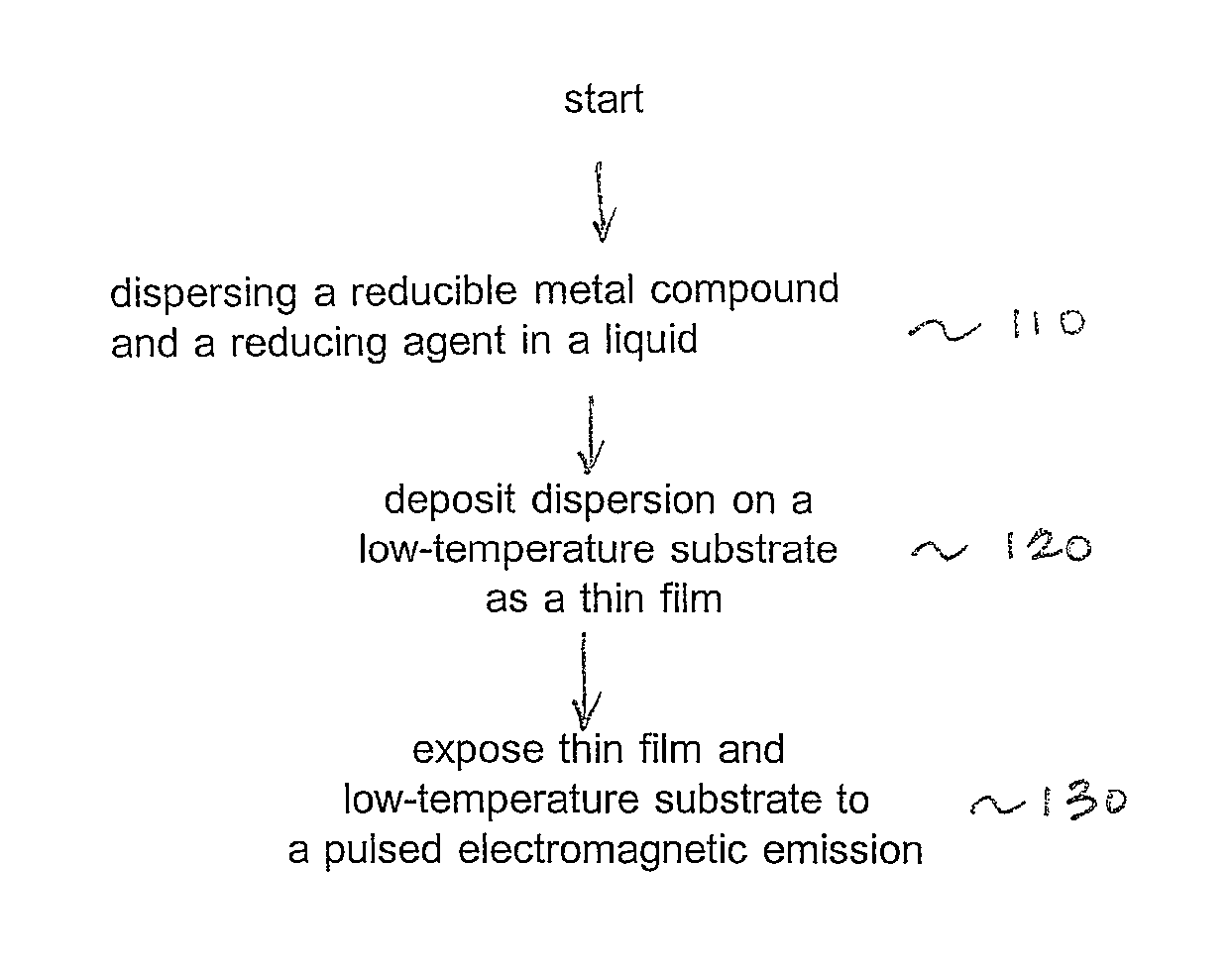

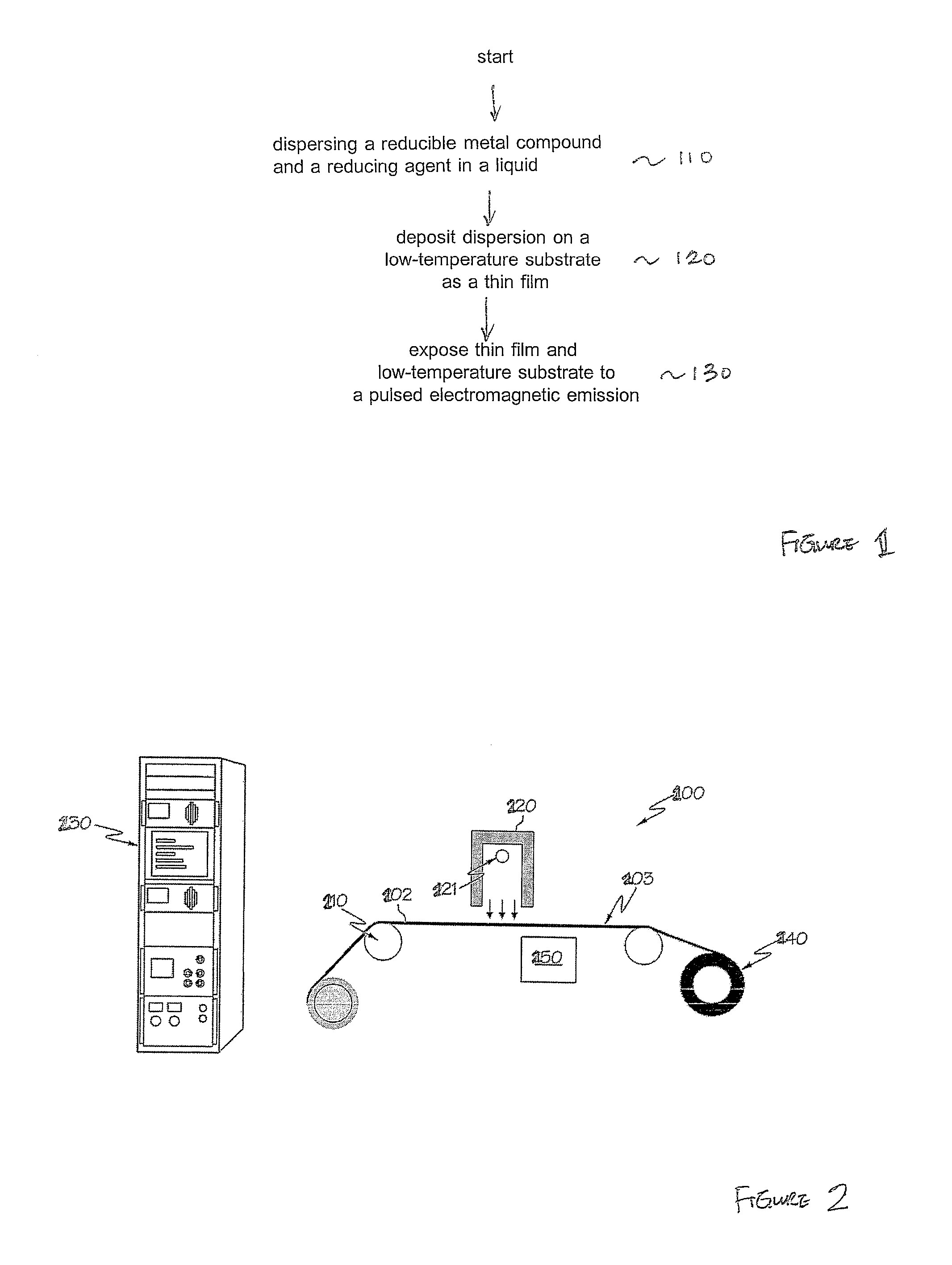

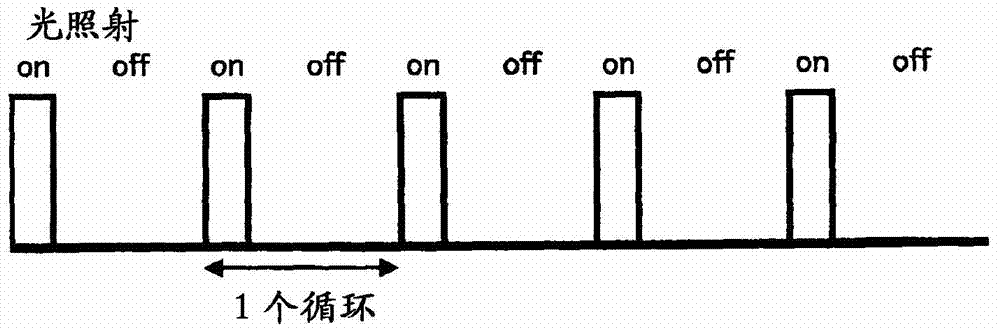

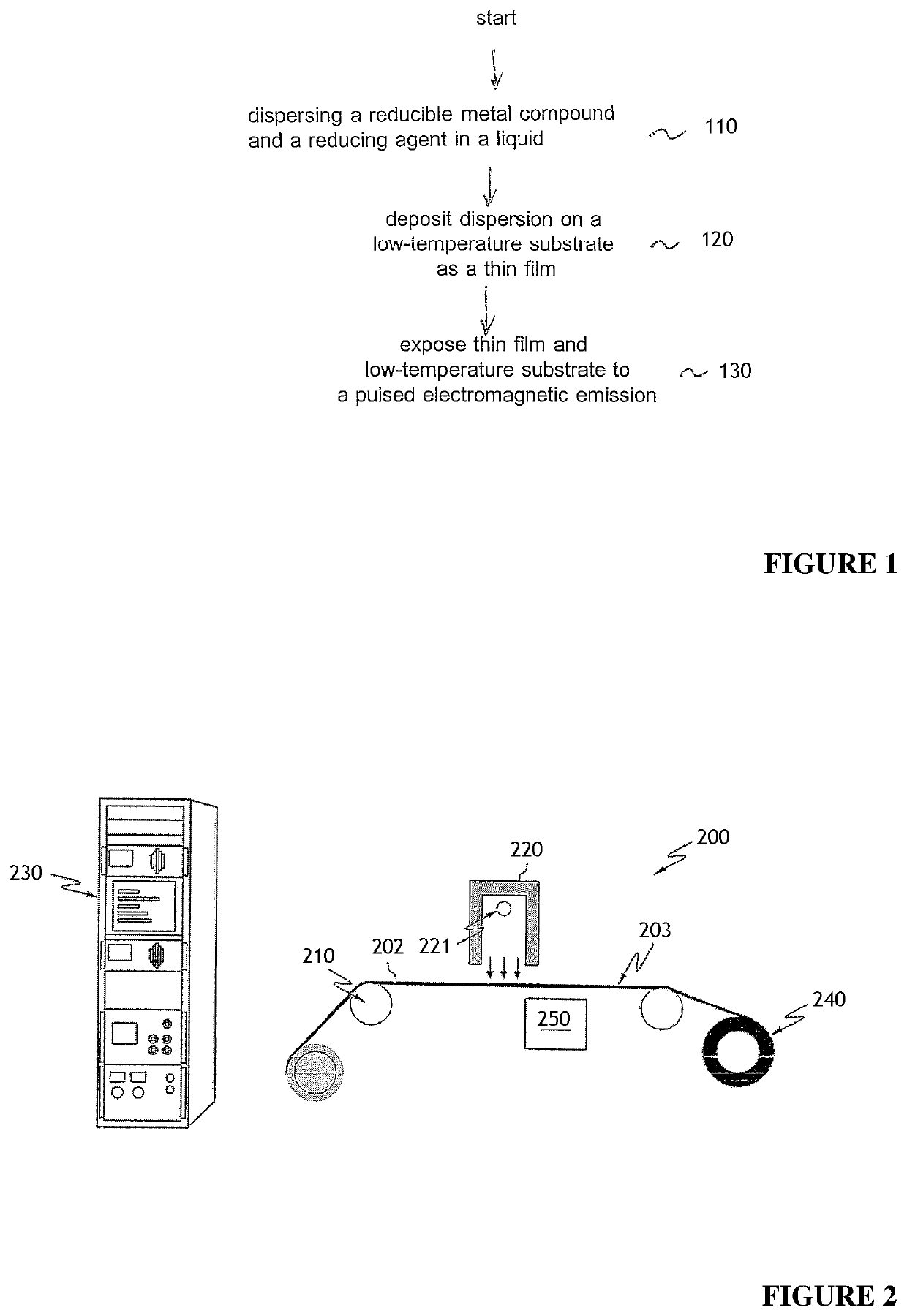

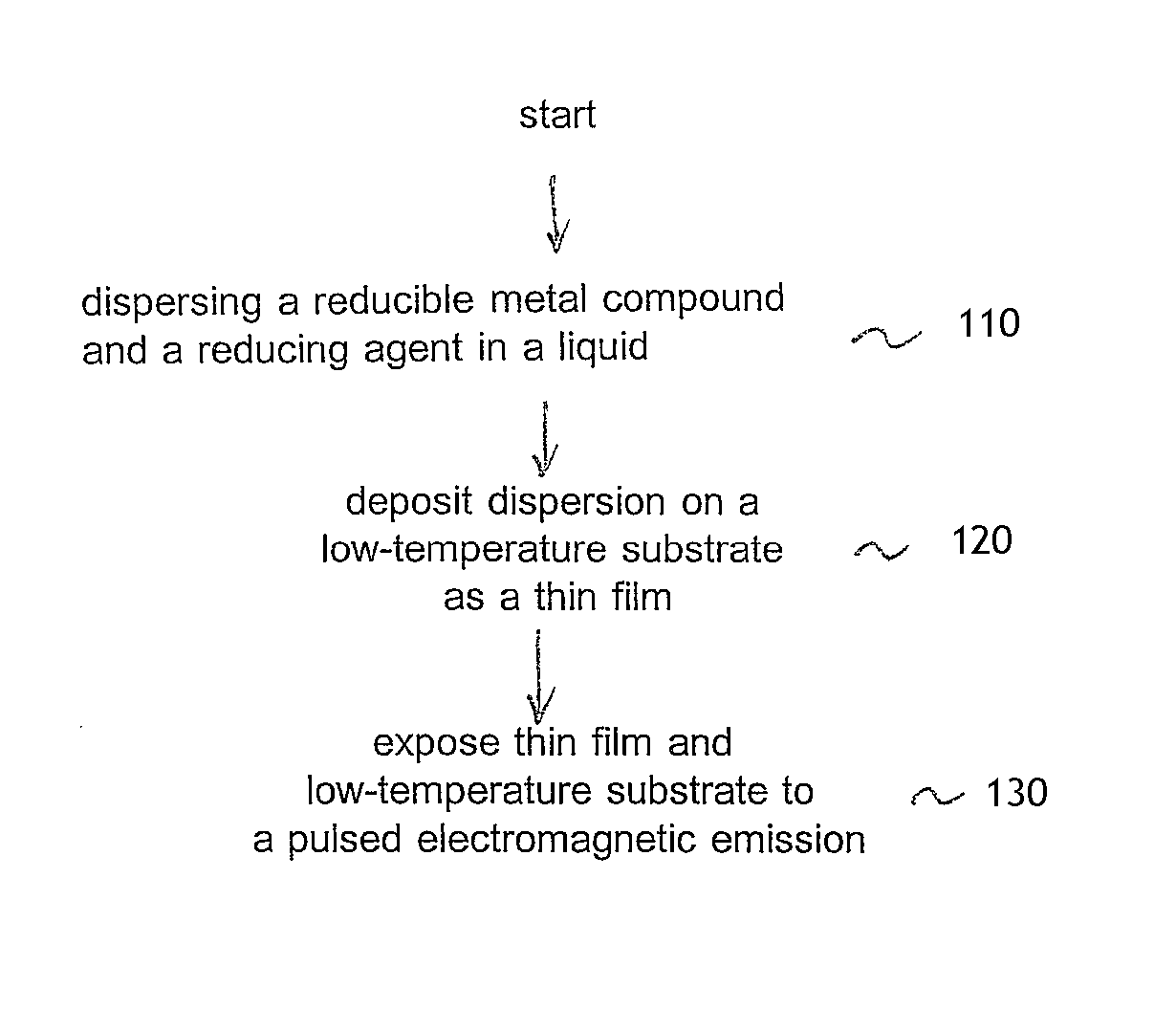

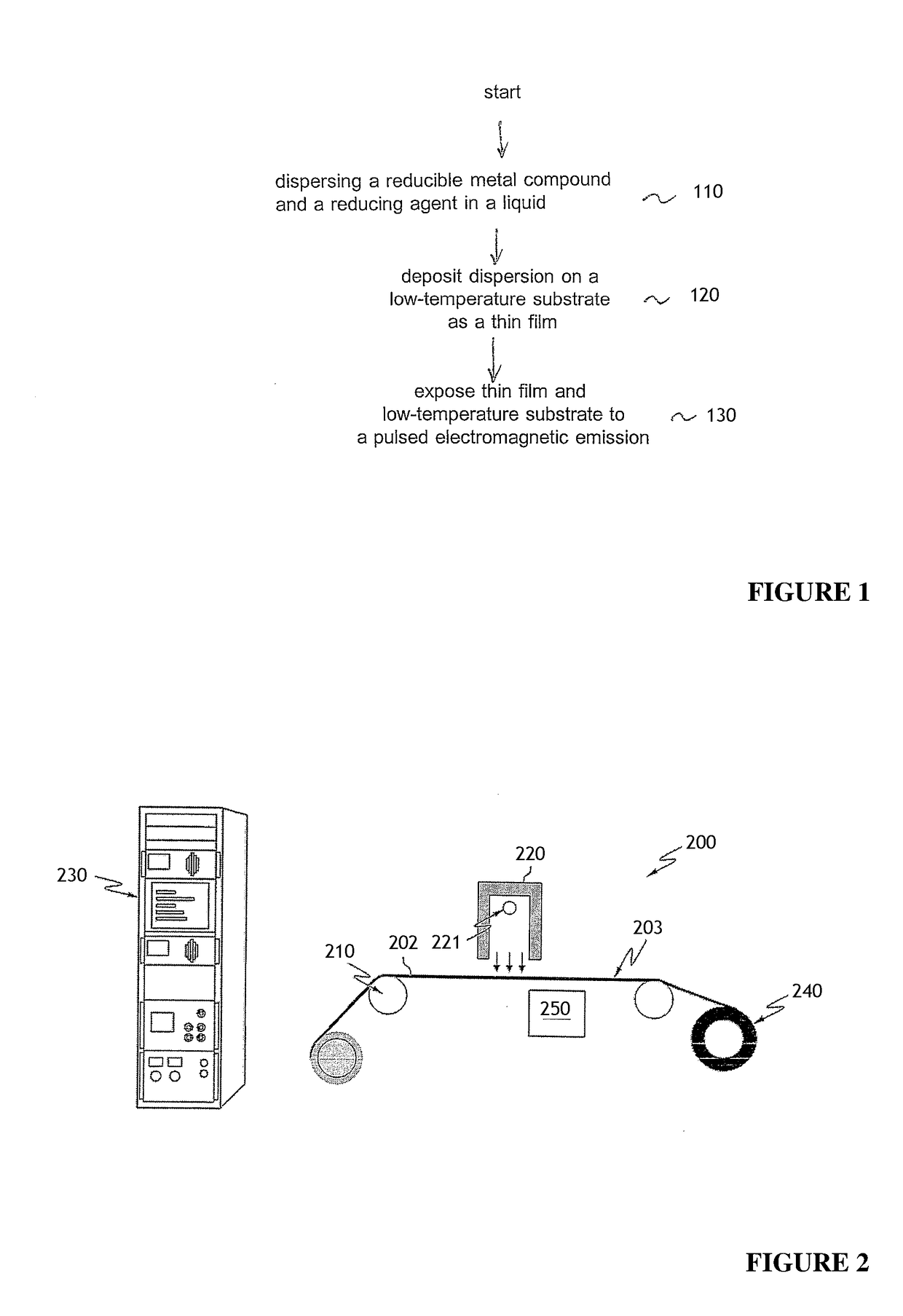

Method for reducing thin films on low temperature substrates

ActiveUS10537029B2Lithography/patterningAlkali metal silicate coatingsChemical reactionThin membrane

A method for producing an electrically conductive thin film on a substrate is disclosed. Initially, a reducible metal compound and a reducing agent are dispersed in a liquid. The dispersion is then deposited on a substrate as a thin film. The thin film along with the substrate is subsequently exposed to a pulsed electromagnetic emission to chemically react with the reducible metal compound and the reducing agent such that the thin film becomes electrically conductive.

Owner:NCC NANO LLC

Conductive element and method of manufacture thereof, wiring element, and master

InactiveCN104185878AIncrease production capacityConductive layers on insulating-supportsPrinted circuit detailsLength wavePhysics

A conductive element comprises: a base having a first wave surface, a second wave surface and a third wave surface; a first layer provided on the first wave surface; and a second layer formed on the second wave surface. The first layer has a laminated structure obtained by laminating two or more layers; the second layer has a single-layer structure or laminated structure comprising some of the layer(s) of the first layer; the first layer and the second layer form a conductive pattern section. The first wave surface, the second wave surface and the third wave surface satisfy the relationship: 0 <=(Am1 / lambdam1)<(Am2 / lambdam2)<(Am3 / lambdam3) <= 1.8 (where Am1 is the average amplitude of oscillation of the first wave surface, Am2 is the average amplitude of oscillation of the second wave surface, Am3 is the average amplitude of oscillation of the third wave surface, lambdam1 is the average wavelength of the first wave surface, lambdam2 is the average wavelength of the second wave surface, and lambdam3 is the average wavelength of the third wave surface).

Owner:SONY CORP

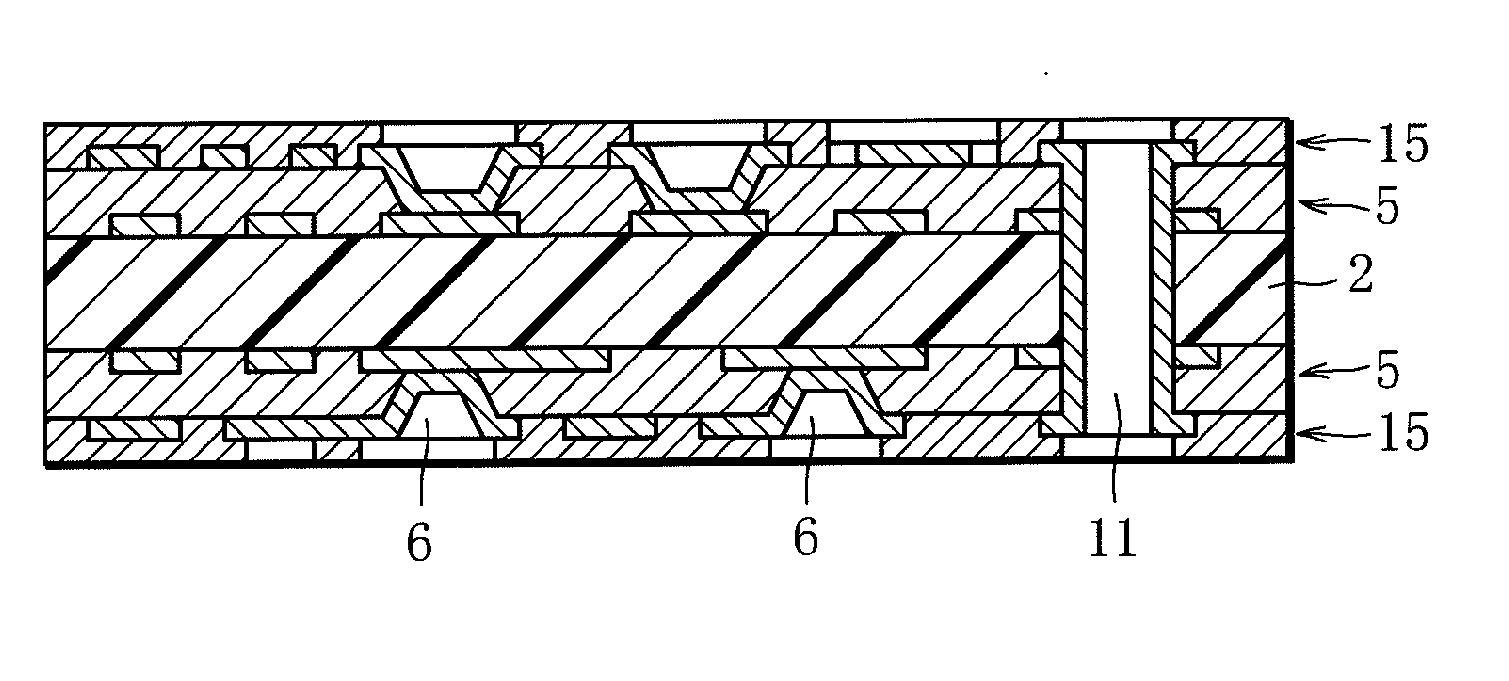

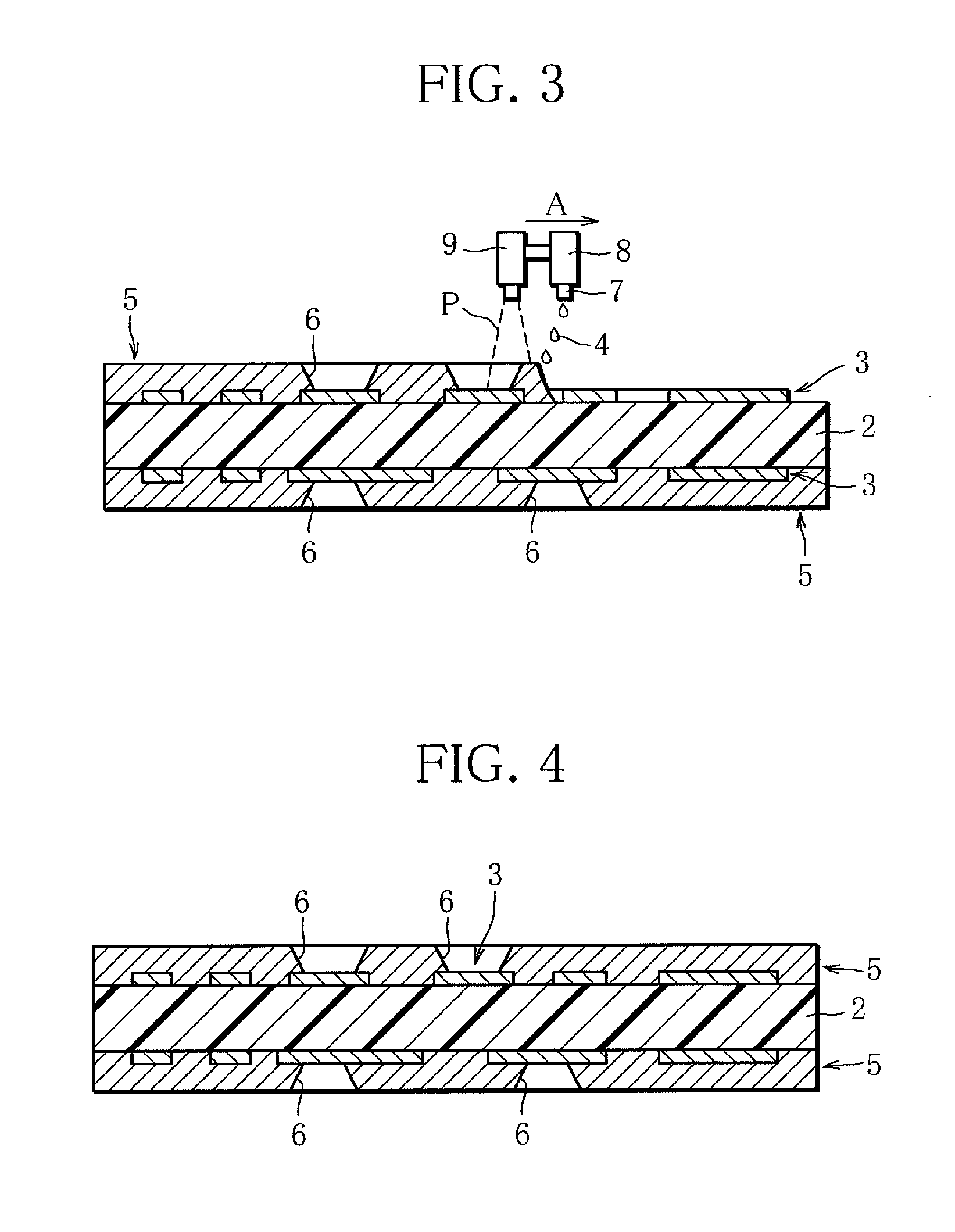

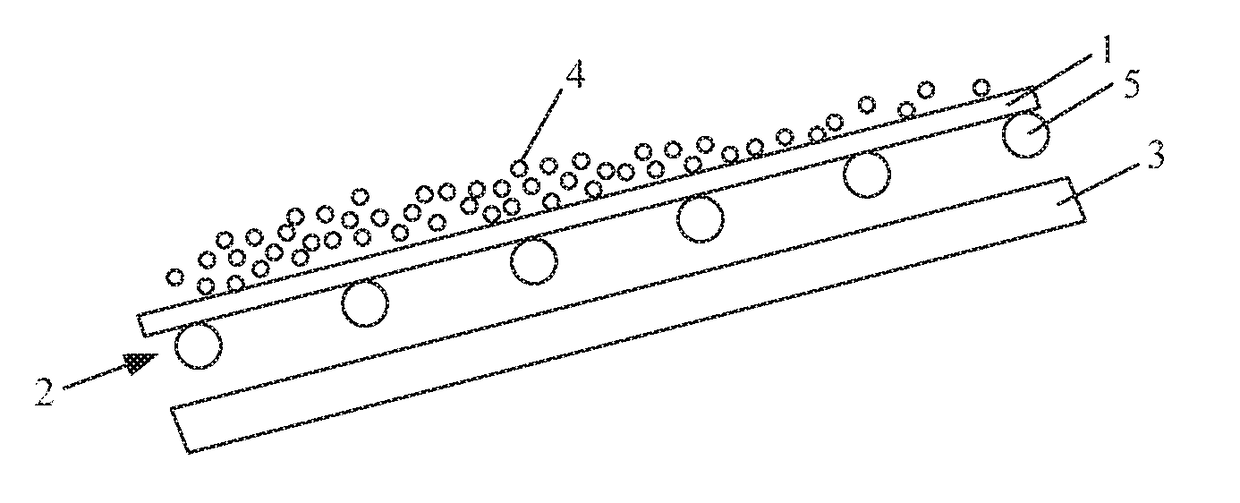

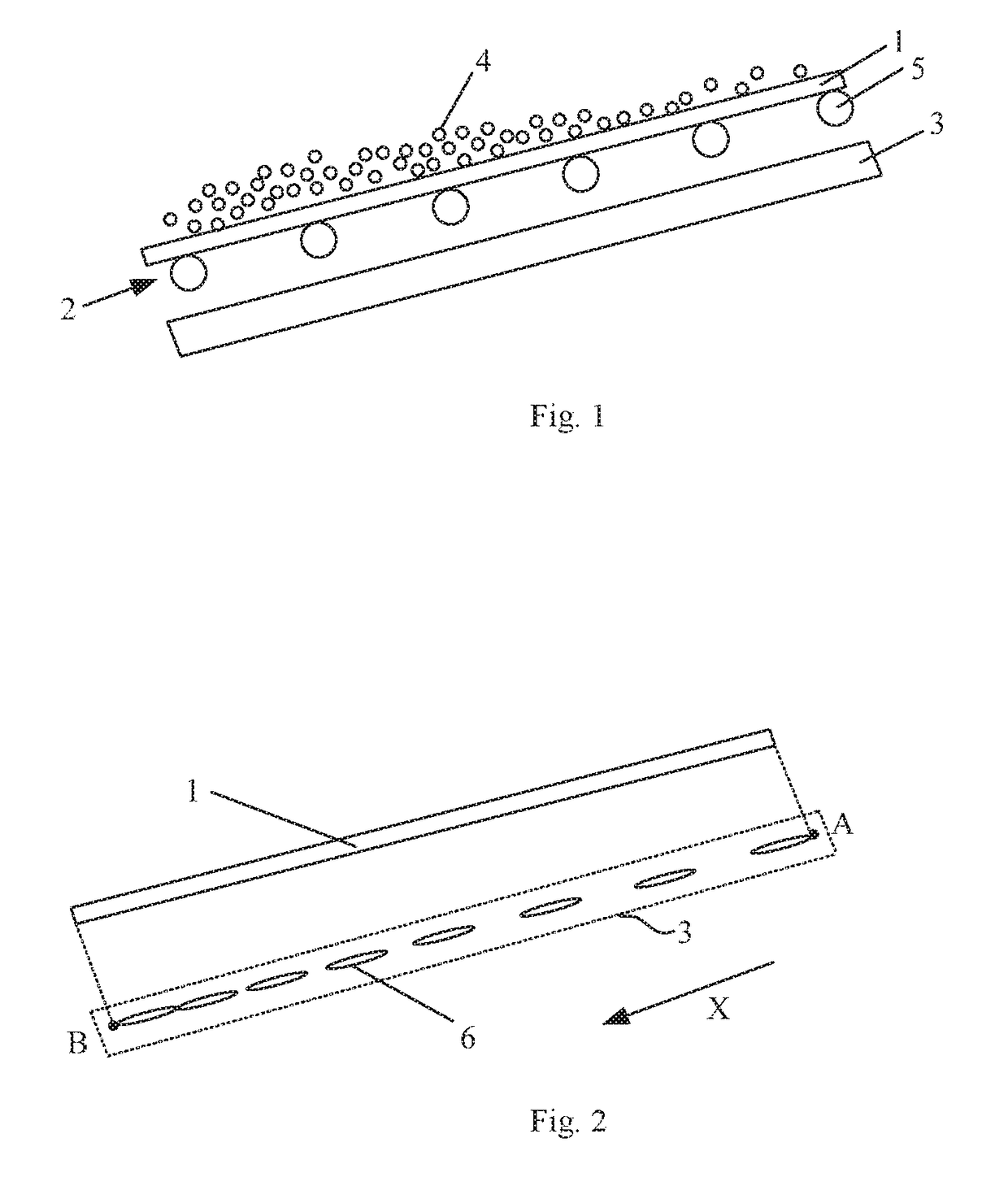

Substrate Manufacturing Method

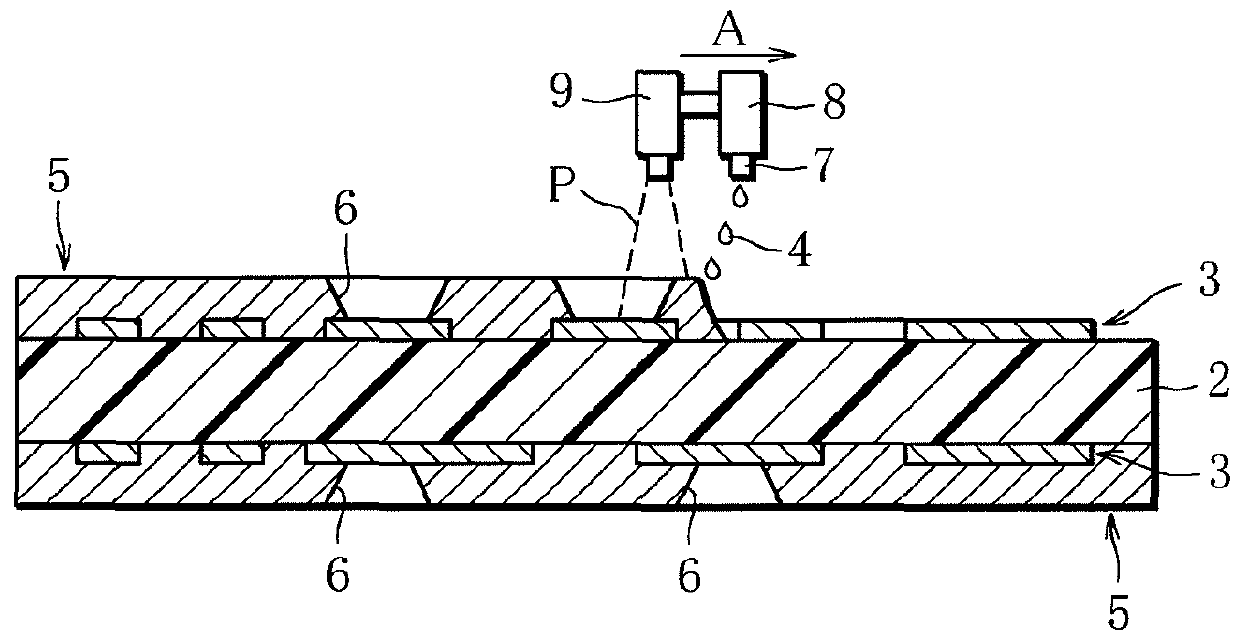

InactiveUS20140224762A1Simple manufacturing processLow costSolid-state devicesSemiconductor/solid-state device manufacturingMetalLaser

A substrate manufacturing method includes an inner layer circuit forming step for partially removing metal films from an insulating base material (2), on both surfaces of which the metal films are stuck, and forming an inner layer circuit (3); and an insulating layer forming step for applying first insulating resin (4) to each of both the surfaces of the insulating base material (2) with an inkjet system and forming an insulating layer (5). In the insulating layer forming step, a via hole (6) from which the inner layer circuit (3) is partially exposed is formed simultaneously with the application of the first insulating resin (4). Consequently, a step of separately forming a via hole with a laser or the like is unnecessary, expenses are relatively low, and it is possible to simplify a manufacturing process.

Owner:MEIKO ELECTRONICS CO LTD

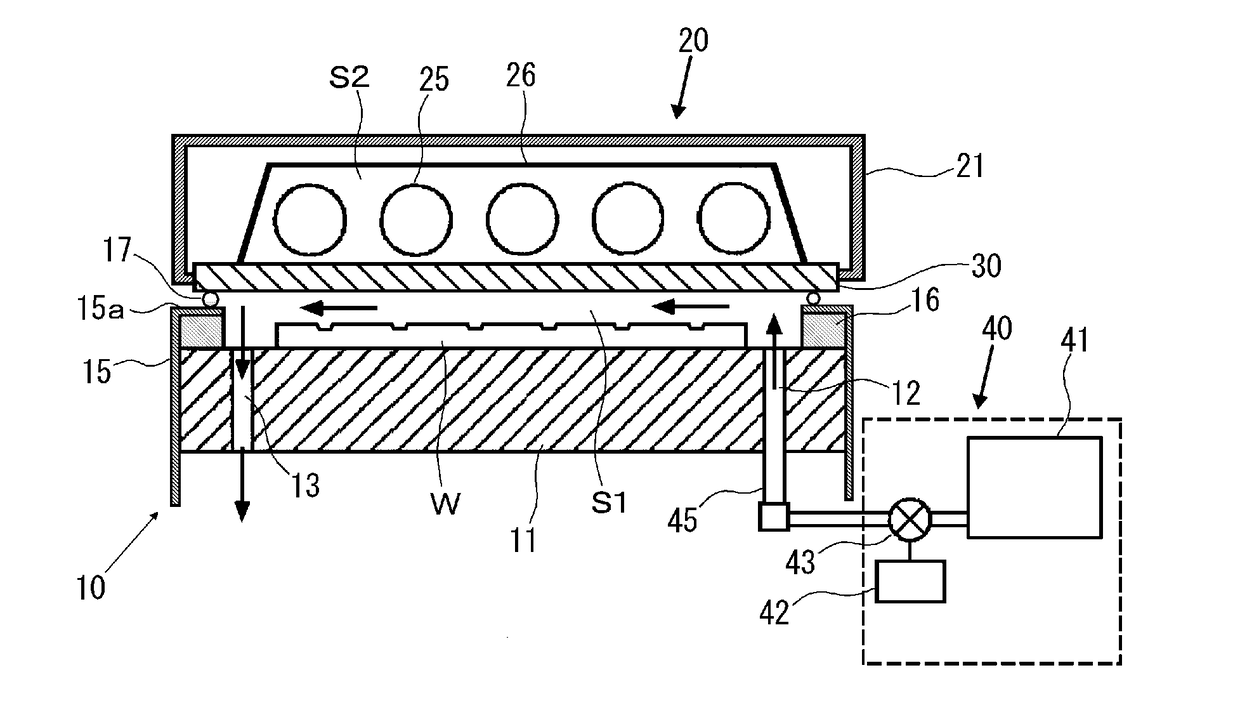

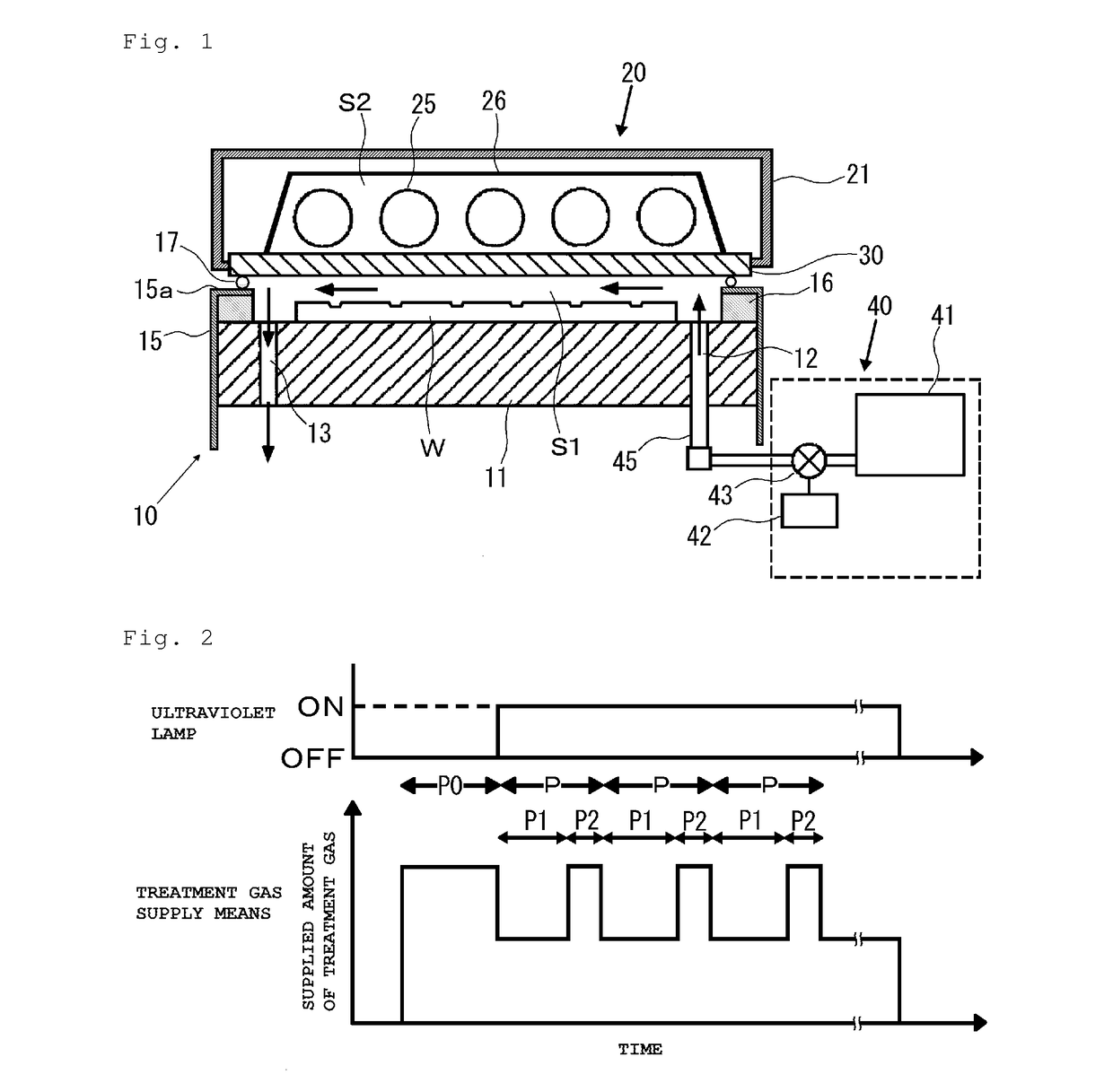

Desmear treatment device and desmear treatment method

InactiveUS20170156217A1Fully removedSemiconductor/solid-state device manufacturingInsulating layers/substrates workingMedicineUltraviolet

The present invention has as its object the provision of a desmear treatment device and a desmear treatment method capable of sufficiently removing smear remaining in a to-be-treated object in a short amount of time. The desmear treatment device of the present invention includes: a treatment chamber in which a to-be-treated object is disposed; a light source unit in which an ultraviolet lamp for irradiating the to-be-treated object with ultraviolet rays is housed; a light transmissive window that is disposed between the treatment chamber and the light source unit and that transmits the ultraviolet rays from the ultraviolet lamps; and treatment gas supply means for supplying a treatment gas containing a source of active species to the treatment chamber. The treatment gas supply means includes a treatment gas supply source and a control unit for controlling a supplied amount of the treatment gas from the treatment gas supply source. The control unit has a function of controlling the treatment gas from the treatment gas supply source to be supplied as a purge gas when irradiating the to-be-treated object with ultraviolet rays.

Owner:USHIO DENKI KK

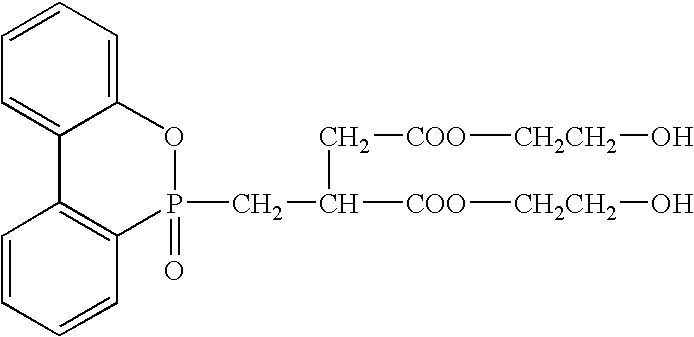

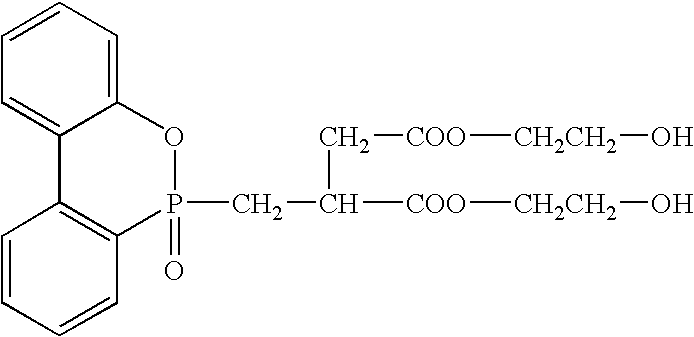

Suspension polymerization compositions, methods and use thereof

ActiveCN107001689AInksTreatment using electric/magnetic/electromagnetic fieldsPolymer scienceOligomer

The disclosure relates to thermosetting reinforced resin compositions and methods of forming boards, sheets and / or films using of porous particulates impregnated with embedded live monomer and / or oligomer and / or polymer configured to partially leach out a functional terminal end of the live monomer and / or oligomer and / or polymer and react with a cross-linking agent and photoinitiated polymer radicals to form a reinforced board, sheet and / or film of hybrid interpenetrating networks.

Owner:NANO DIMENSIONS TECH LTD

Method for Reducing Thin Films on Low Temperature Substrates

A method for producing an electrically conductive thin film on a substrate is disclosed. Initially, a reducible metal compound and a reducing agent are dispersed in a liquid. The dispersion is then deposited on a substrate as a thin film. The thin film along with the substrate is subsequently exposed to a pulsed electromagnetic emission to chemically react with the reducible metal compound and the reducing agent such that the thin film becomes electrically conductive.

Owner:NCC NANO LLC

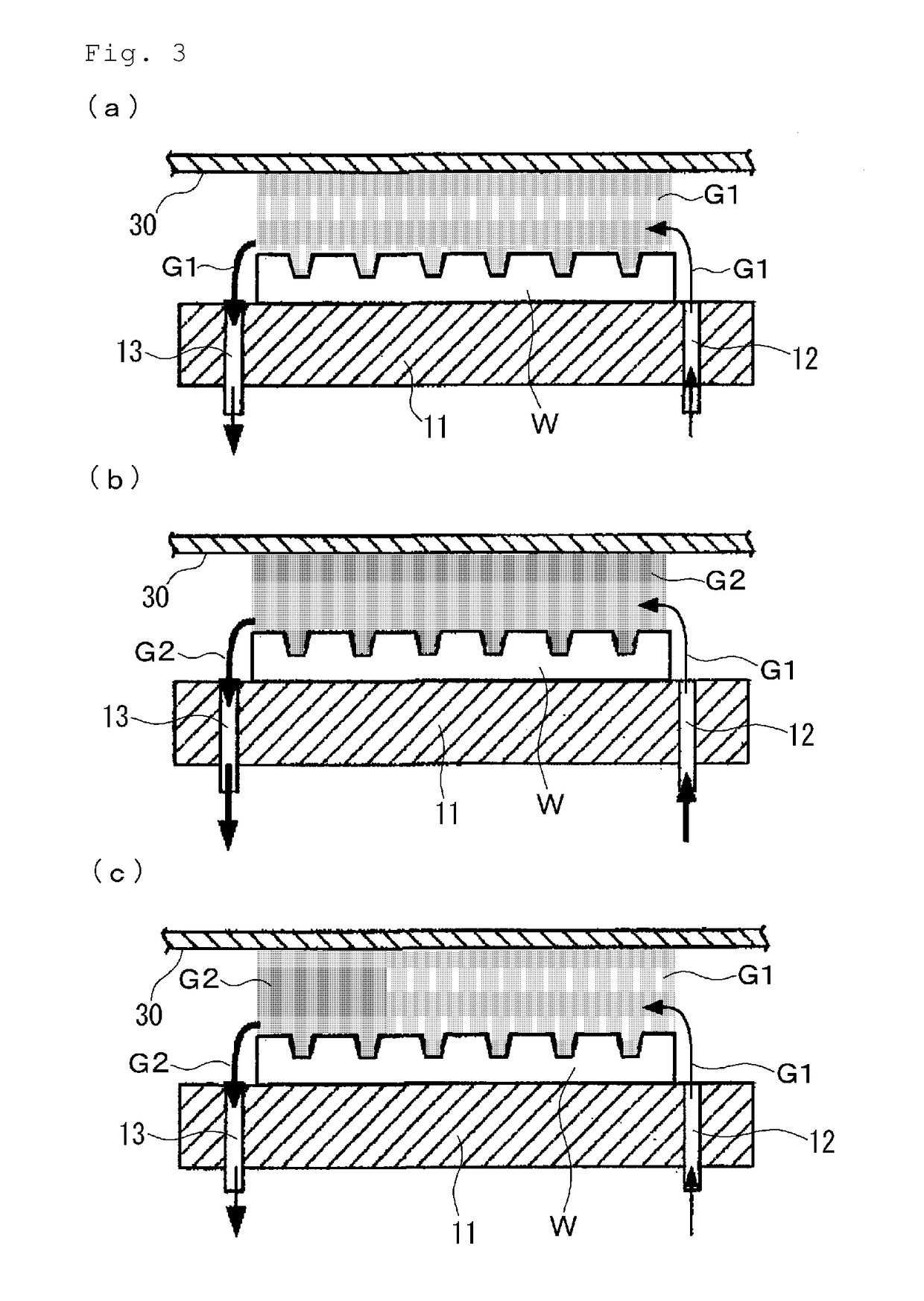

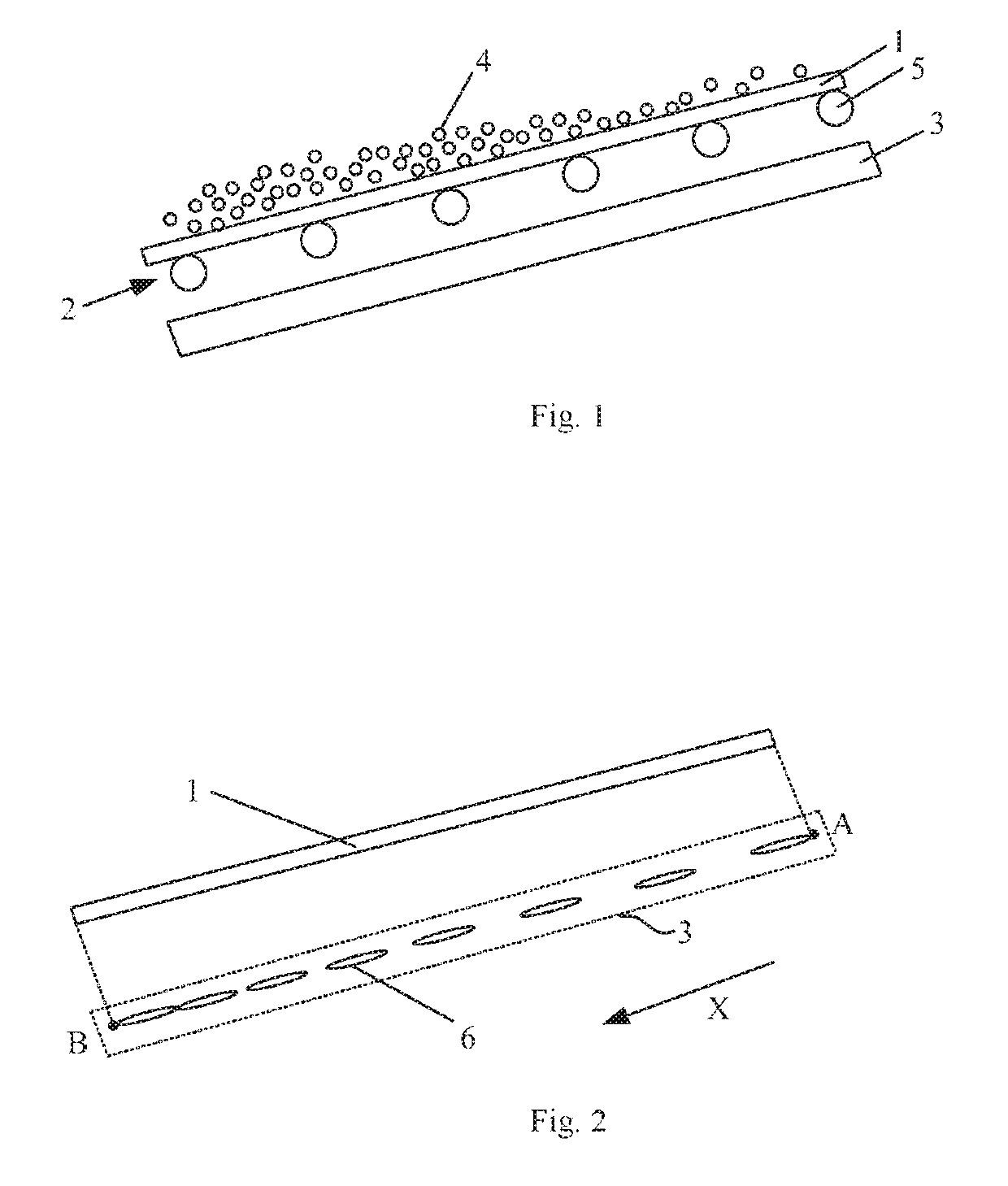

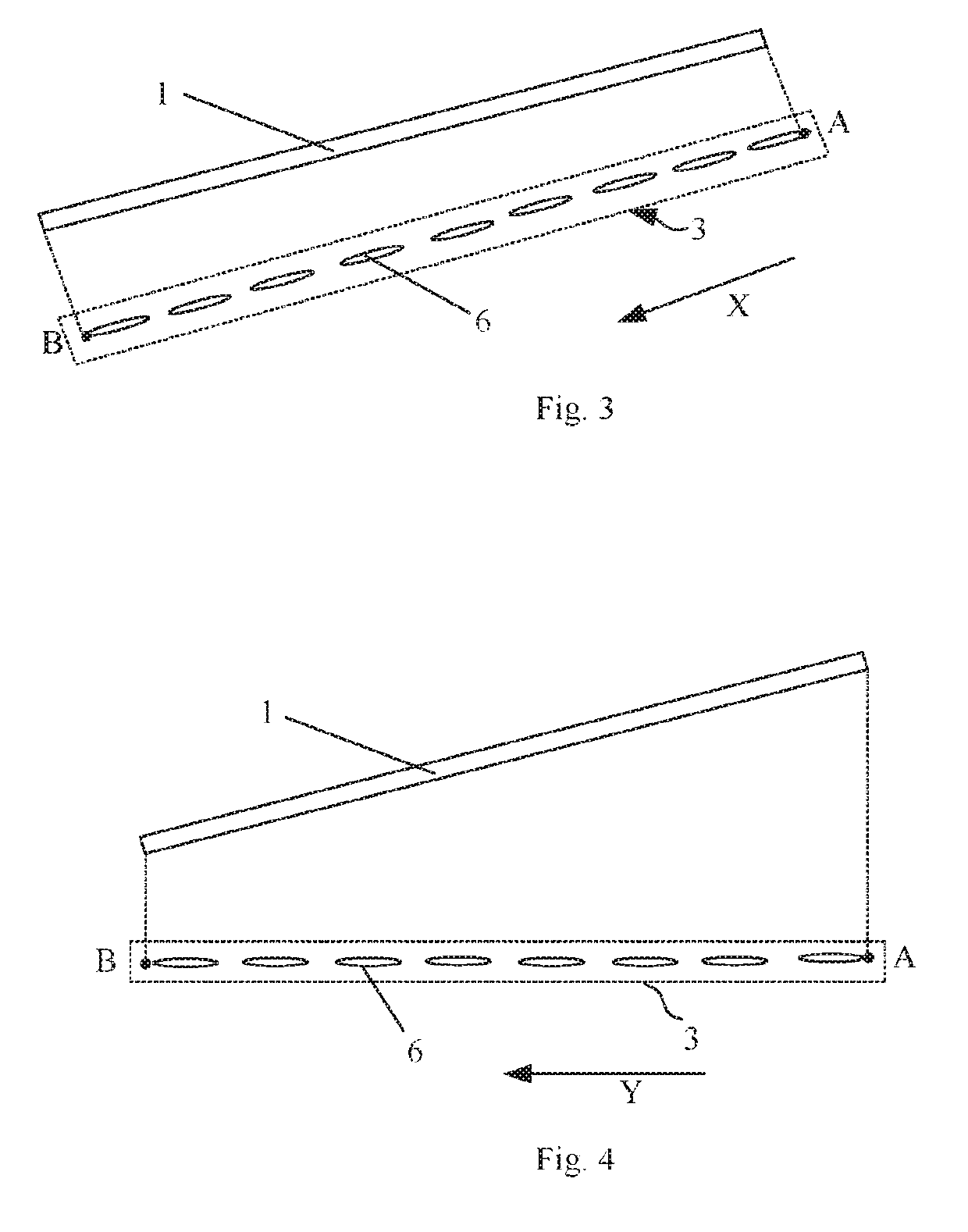

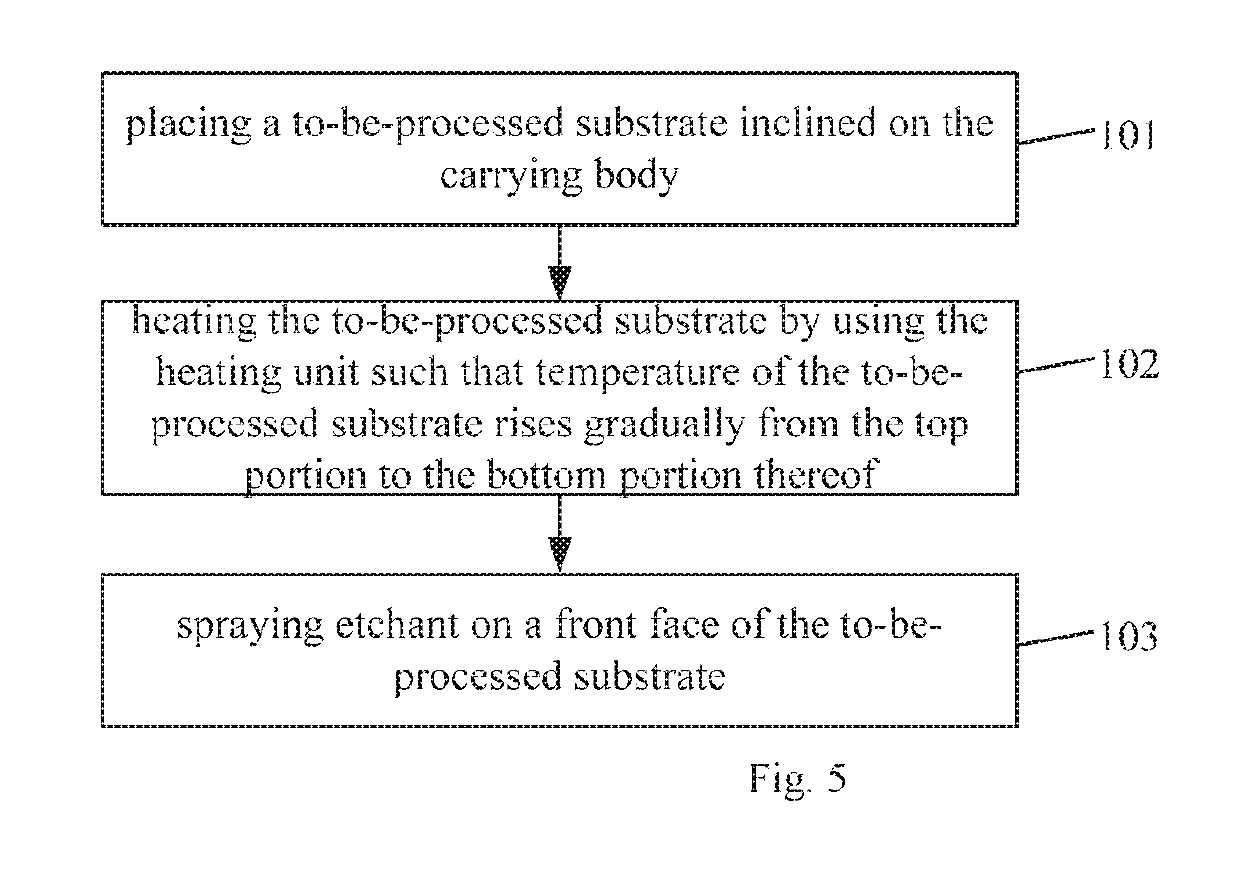

Carrying device, wet etching apparatus and usage method thereof

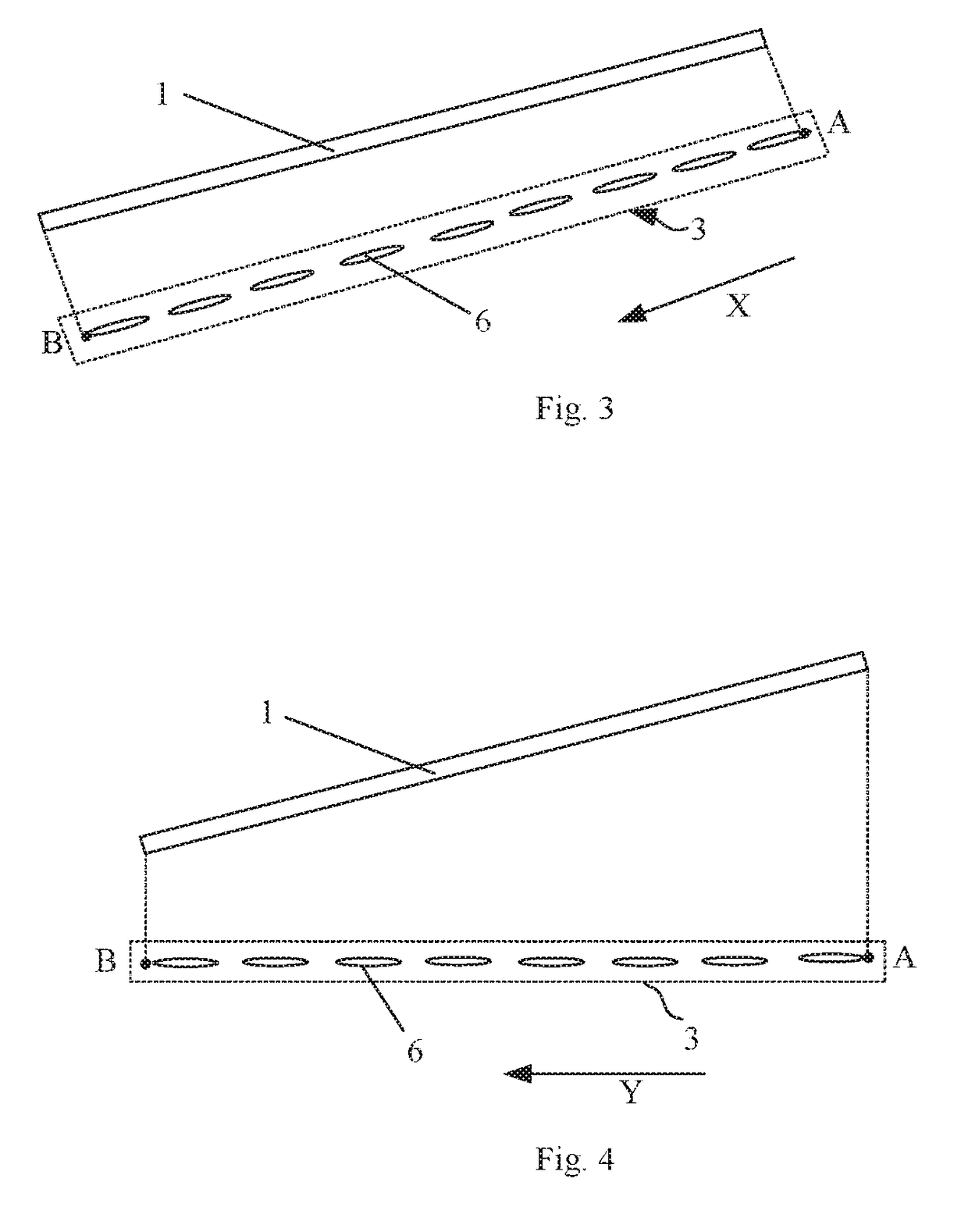

ActiveUS20170202091A1Improve etch uniformityImprove uniformityPrinted circuit liquid treatmentSolid-state devicesElectrical and Electronics engineeringEtching rate

The present invention discloses a carrying device, a wet etching apparatus and a usage method thereof. The carrying device comprises a carrying body and a heating unit both disposed under a to-be-processed substrate, the carrying body is used for carrying the to-be-processed substrate such that the to-be-processed substrate is placed inclined; the heating unit is used for heating the to-be-processed substrate, such that temperature of the to-be-processed substrate rises gradually from a top portion to a bottom portion thereof. In the technical solution of the present invention, by disposing the heating unit under the to-be-processed substrate, the temperature of the to-be-processed substrate rises gradually from the top portion to the bottom portion thereof, thus etch rate of the etchant on the bottom portion of the to-be-processed substrate can be increased, and uniformity of etch rate in the inclined wet etching process is improved.

Owner:BOE TECH GRP CO LTD +1

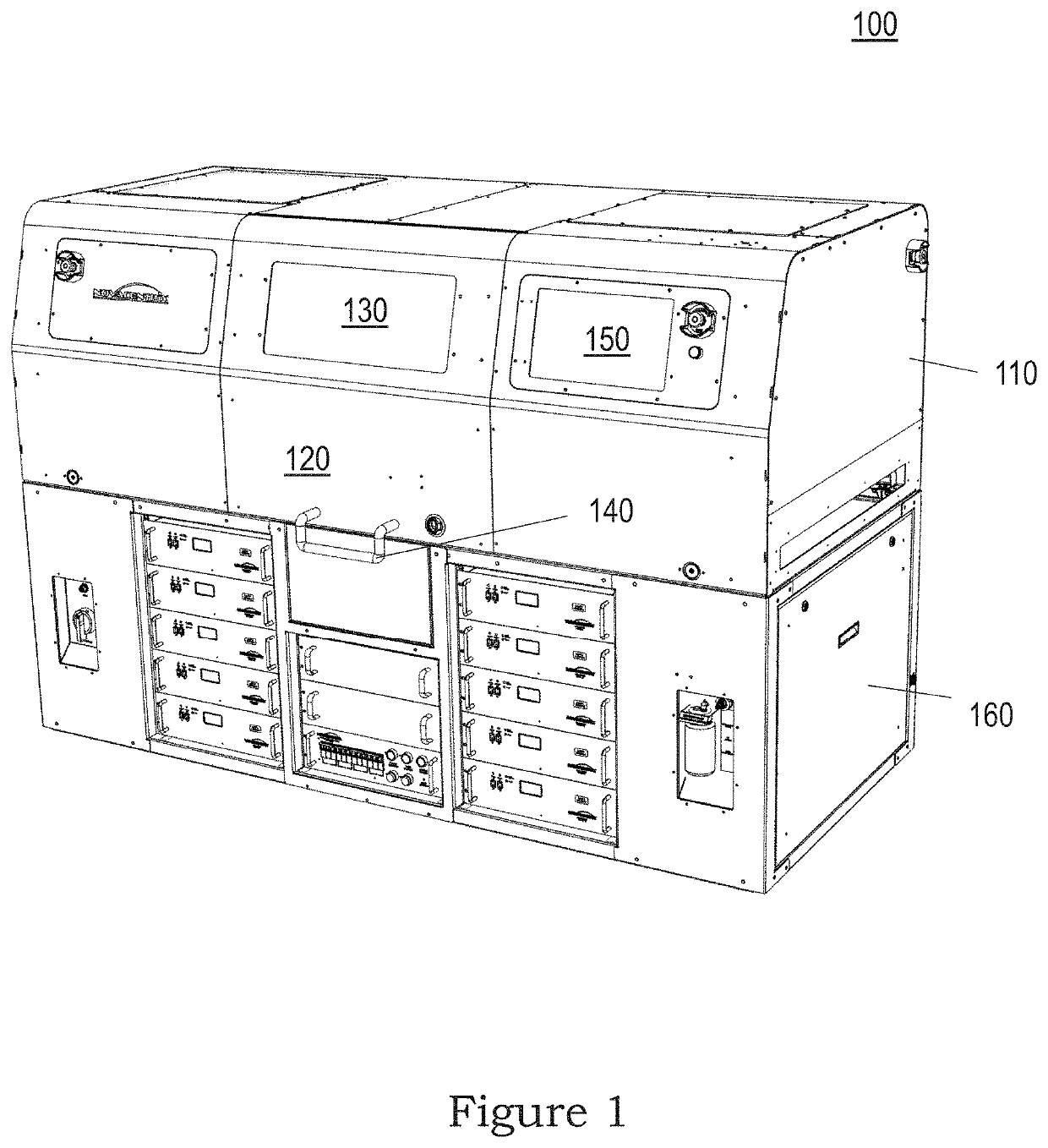

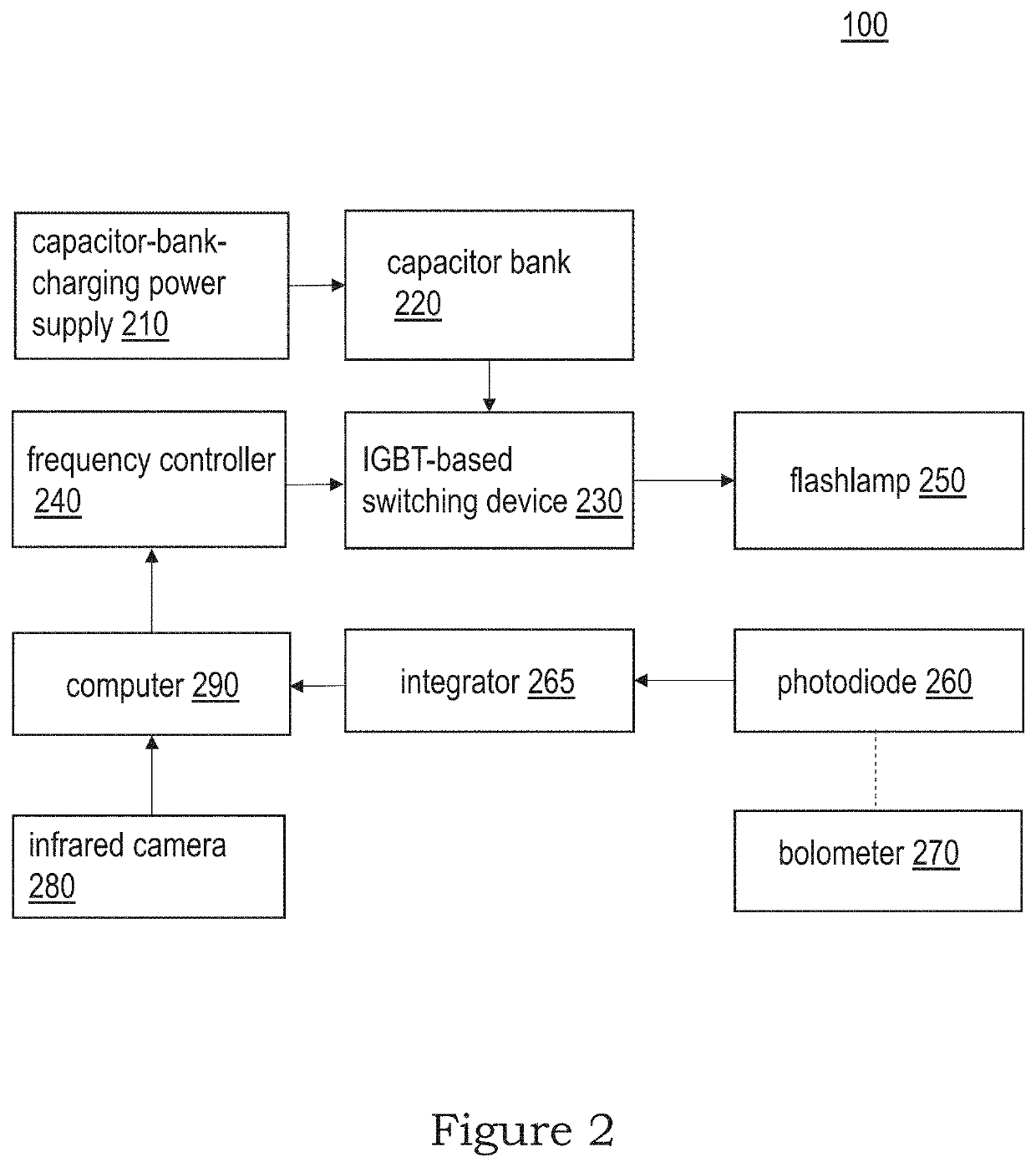

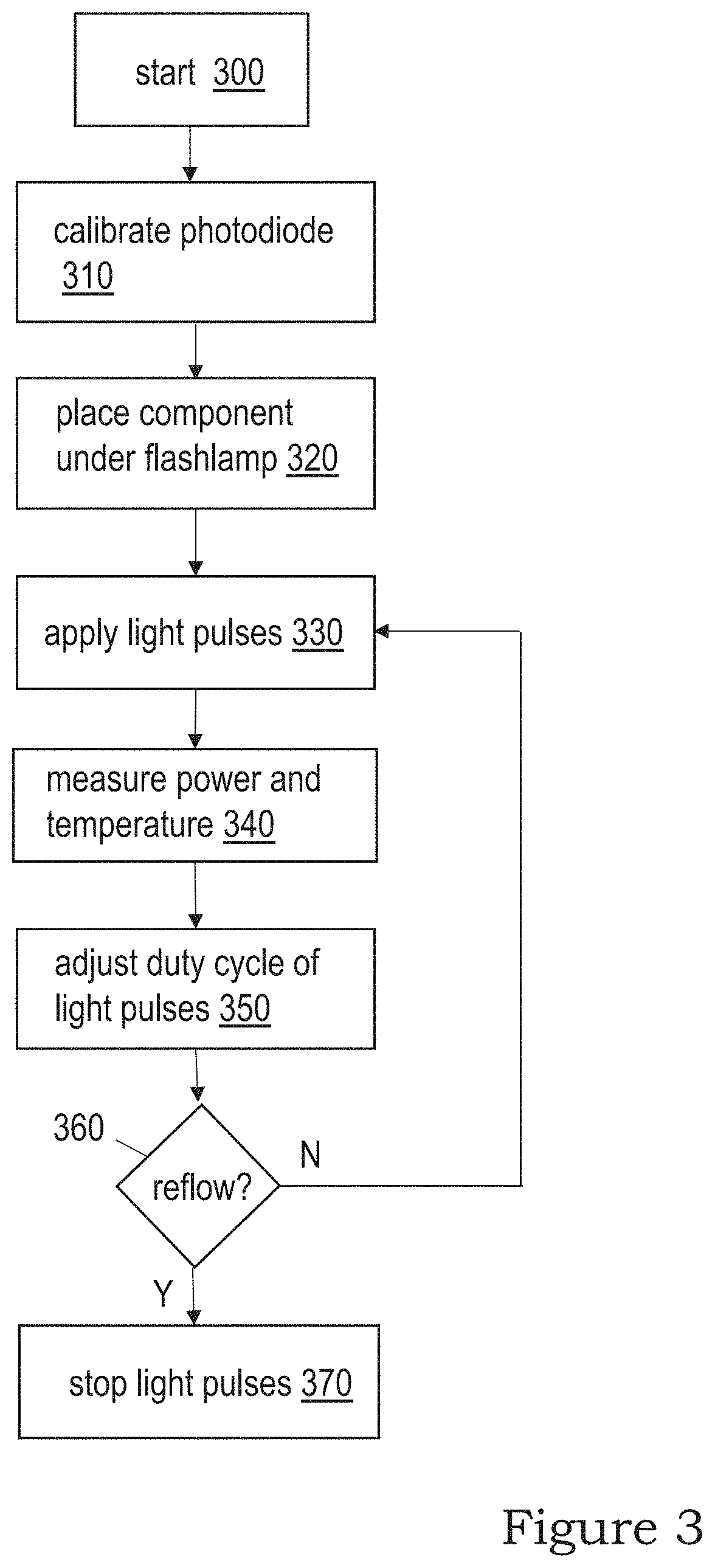

Method for connecting surface-mount electronic components to a circuit board

A method for connecting an electronic component to a circuit board is disclosed. Initially, a substrate and an electronic component having solder located between them are placed under a flashlamp. Multiple light pulses from the flashlamp are applied to the electronic component, substrate and solder until the solder reflows. During the application of the light pulses, the power of one of the light pulses from the flashlamp and the temperature of the electronic component are measured, the measured power is converted to radiant exposure, and in response to the measured temperature of the electronic component, the duty cycle of a next light pulse is adjusted adaptively according to the radiant exposure of the one light pulse.

Owner:PULSEFORGE INC

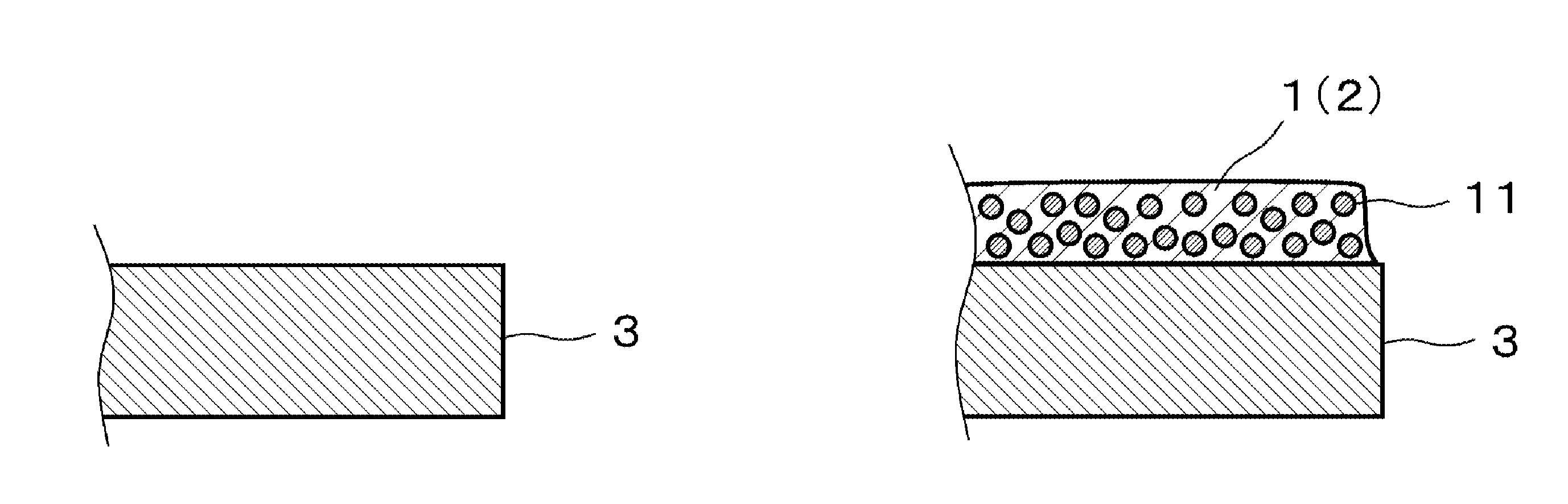

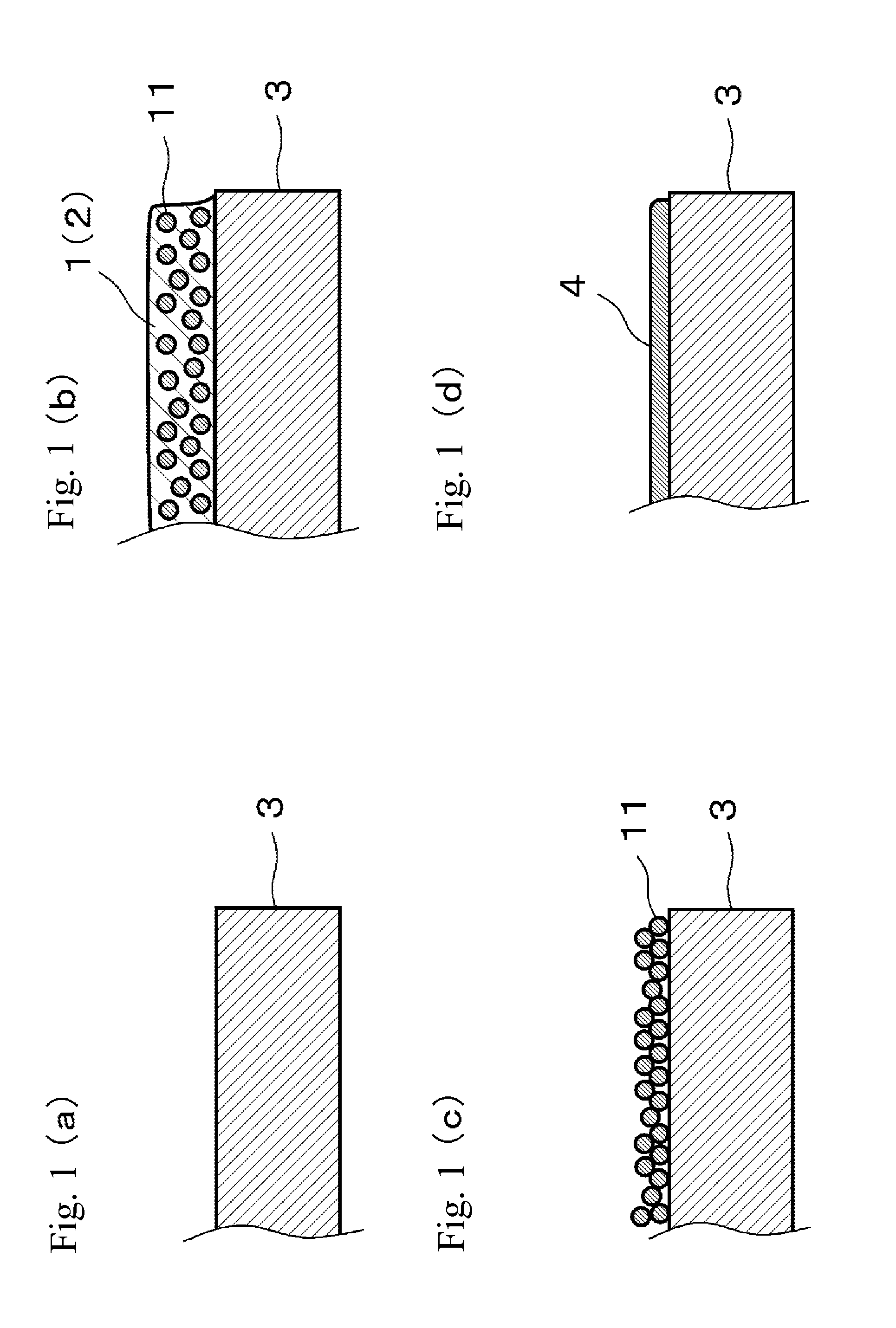

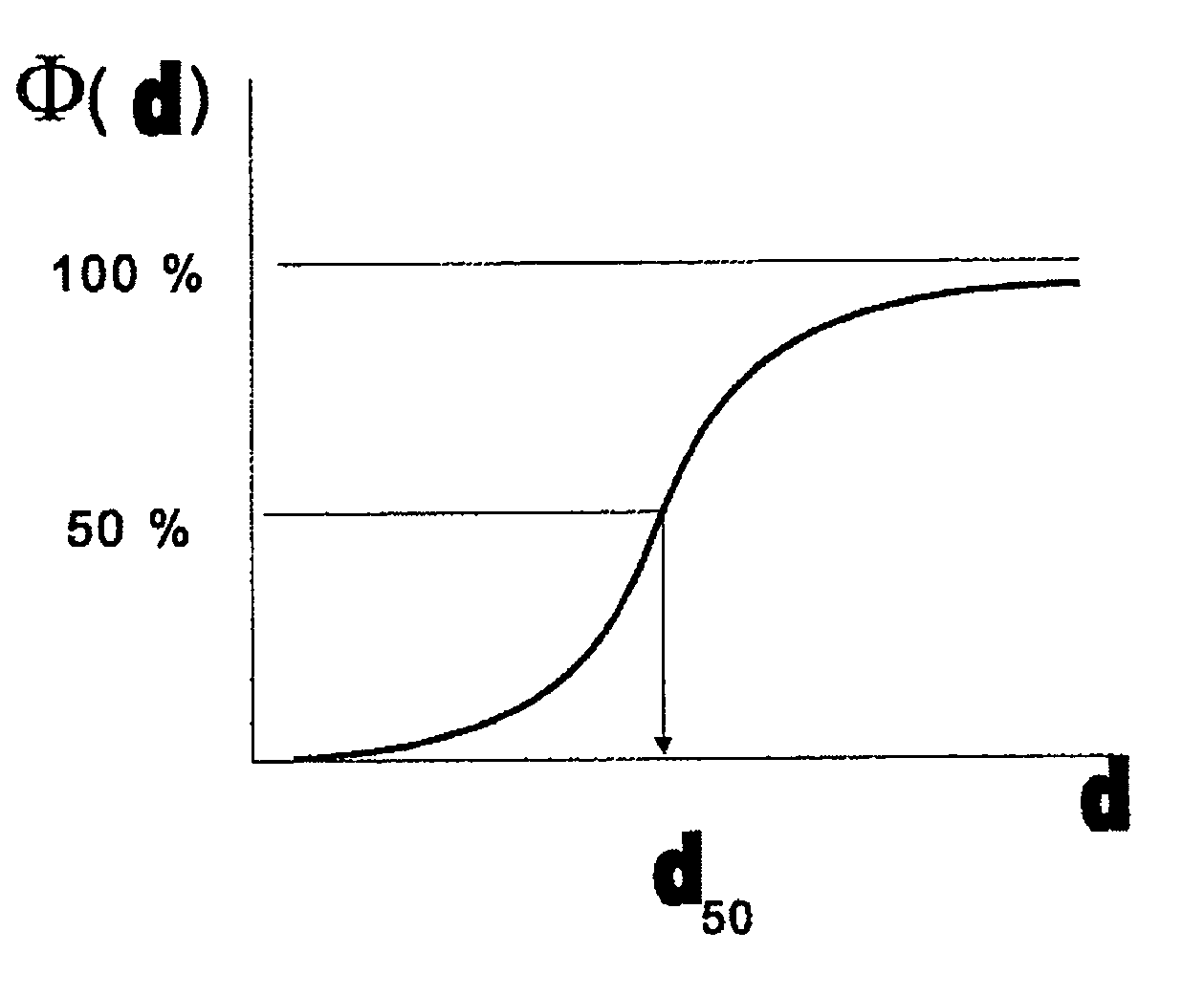

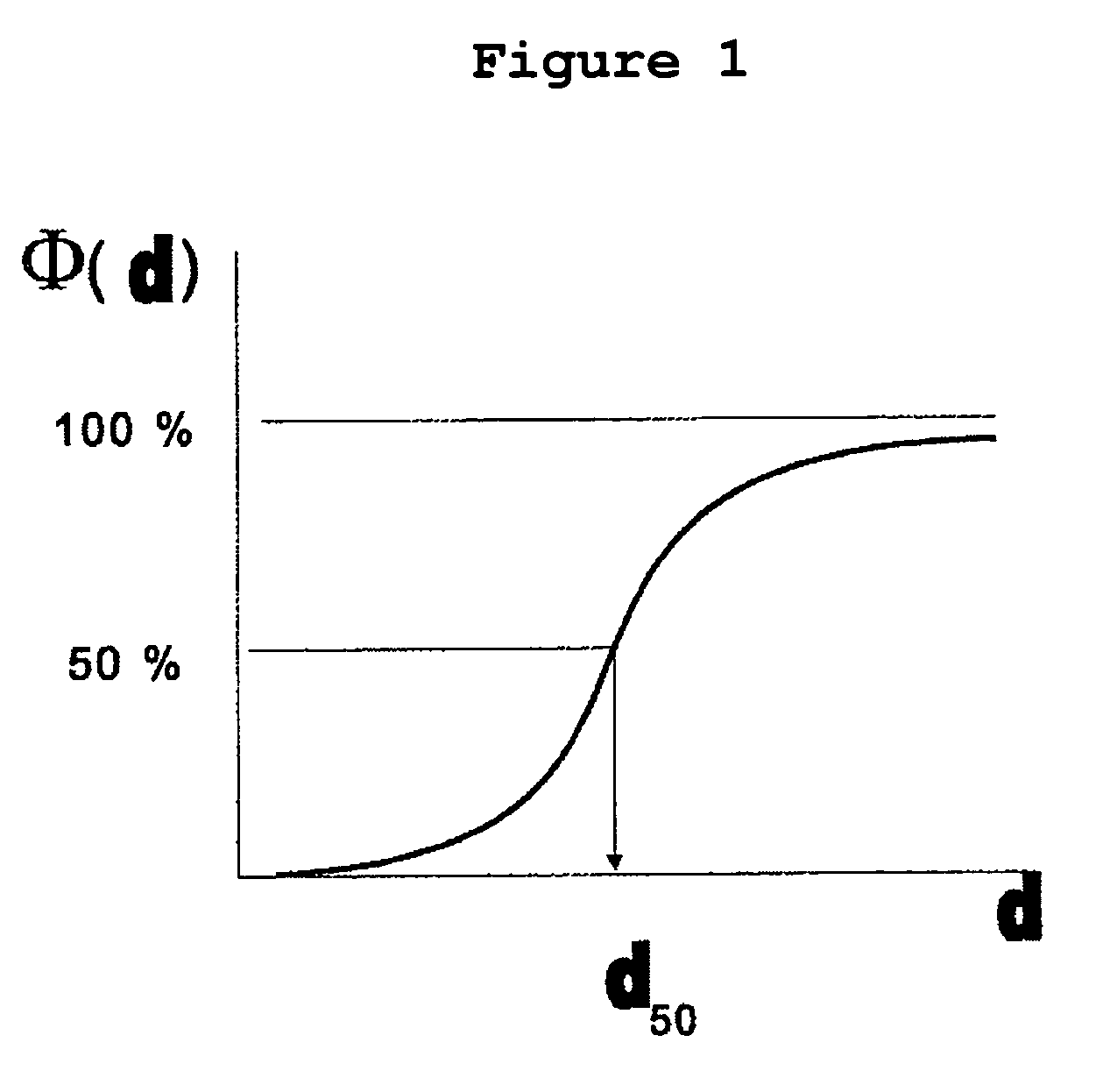

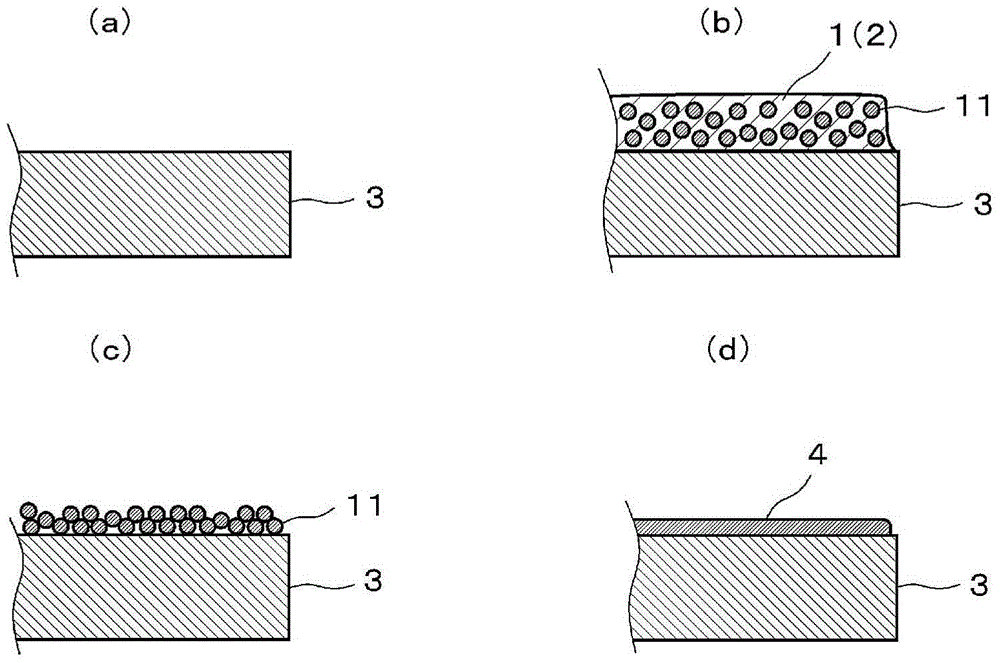

Copper-fine-particle dispersion liquid, conductive-film formation method, and circuit board

ActiveCN105210155AAdditive manufacturingConductive layers on insulating-supportsRoom temperatureCopper oxide

Provided is a copper-fine-particle dispersion liquid with which photosintering can be used to easily form a conductive film having a low electrical resistance. This copper-fine-particle dispersion liquid (1) includes a dispersion medium, and copper fine particles (11) dispersed in the dispersion medium. The copper-fine-particle dispersion liquid (1) includes a sintering promoter. The sintering promoter is a compound which removes copper oxide from copper at a temperature higher than room temperature. Accordingly, during photosintering of the copper fine particles (11), the sintering promoter removes a surface oxide film on the copper fine particles (11).

Owner:ISHIHARA CHEM

Circuit board structure and manufacturing method thereof

ActiveCN107041068AReduce manufacturing costOmit the paste stepPrinted circuit aspectsLaminating printed circuit boardsEngineeringBoard structure

Owner:ICHIA TECH

Carrying device, wet etching apparatus and usage method thereof

ActiveUS10506720B2Improve uniformityEtch rate reductionPrinted circuit liquid treatmentSolid-state devicesMaterials scienceEtching rate

Owner:BOE TECH GRP CO LTD +1

An anti-jamming circuit board and terminal

ActiveCN111586960BMagnetic field offset compensationPrinted circuit aspectsAnti jammingHemt circuits

Owner:HUAWEI TECH CO LTD

Substrate manufacturing method

InactiveUS9380711B2Low costSimple manufacturing processPrinted circuit assemblingSolid-state devicesPolyresinMetal

A substrate manufacturing method includes an inner layer circuit forming step for partially removing metal films from an insulating base material (2), on both surfaces of which the metal films are stuck, and forming an inner layer circuit (3); and an insulating layer forming step for applying first insulating resin (4) to each of both the surfaces of the insulating base material (2) with an inkjet system and forming an insulating layer (5). In the insulating layer forming step, a via hole (6) from which the inner layer circuit (3) is partially exposed is formed simultaneously with the application of the first insulating resin (4). Consequently, a step of separately forming a via hole with a laser or the like is unnecessary, expenses are relatively low, and it is possible to simplify a manufacturing process.

Owner:MEIKO ELECTRONICS CO LTD

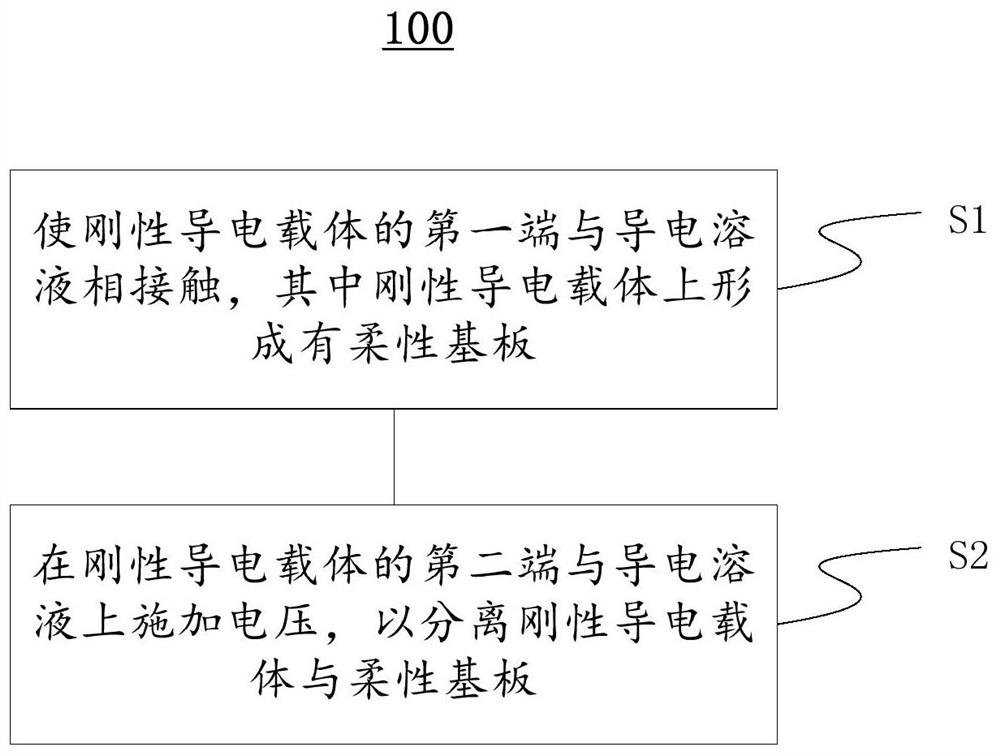

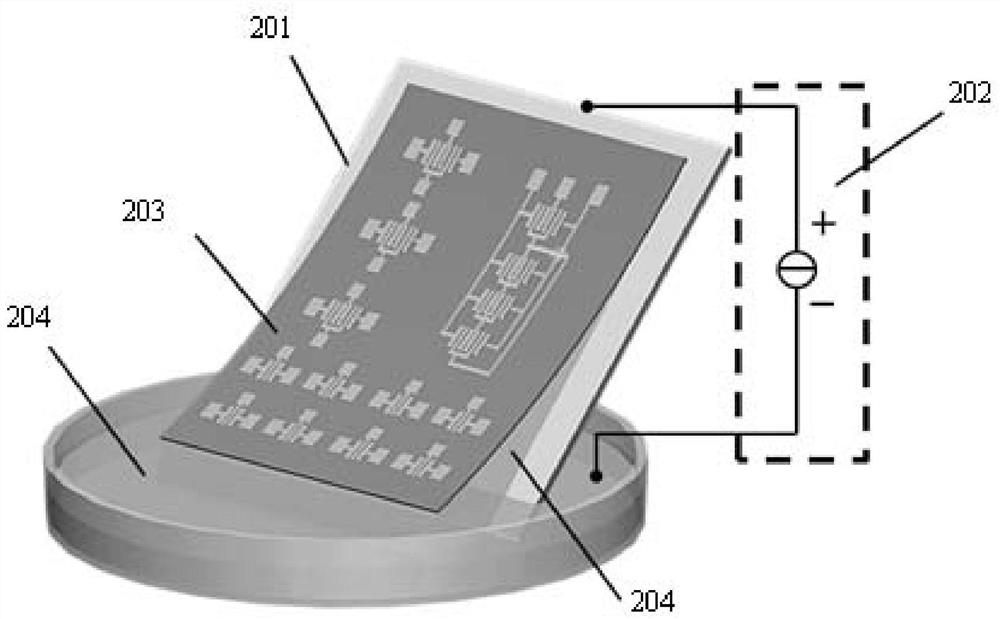

Method of Separating Flexible Substrate and Rigid Conductive Carrier

ActiveCN110072336BTreatment using electric/magnetic/electromagnetic fieldsMultilayer circuit manufactureVoltageElectrically conductive

Owner:BEIJING HUATAN TECH CO LTD

Suspension polymerization composition, method and use thereof

ActiveCN107001689BInksTreatment using electric/magnetic/electromagnetic fieldsPolymer scienceOligomer

The present disclosure relates to thermosetting reinforced resin compositions and methods of forming plates, sheets and / or films using porous particles impregnated with embedded reactive monomers and / or oligomers and / or polymers, the The porous particles are configured to partially leach functional end portions of reactive monomers and / or oligomers and / or polymers and react with cross-linking agents and photo-initiated polymer radicals to form enhanced interpenetrating hybrid networks Plates, sheets and / or films.

Owner:NANO DIMENSIONS TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com