Conductive-pattern formation method and composition for forming conductive pattern via light exposure or microwave heating

A conductive pattern, microwave heating technology, applied in the direction of conductive pattern formation, conductive materials dispersed in non-conductive inorganic materials, conductive coatings, etc., can solve the problem of copper oxide particle residue, conductive pattern conductivity can not be fully improved, conductive pattern pores High conductivity and other problems, to achieve the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

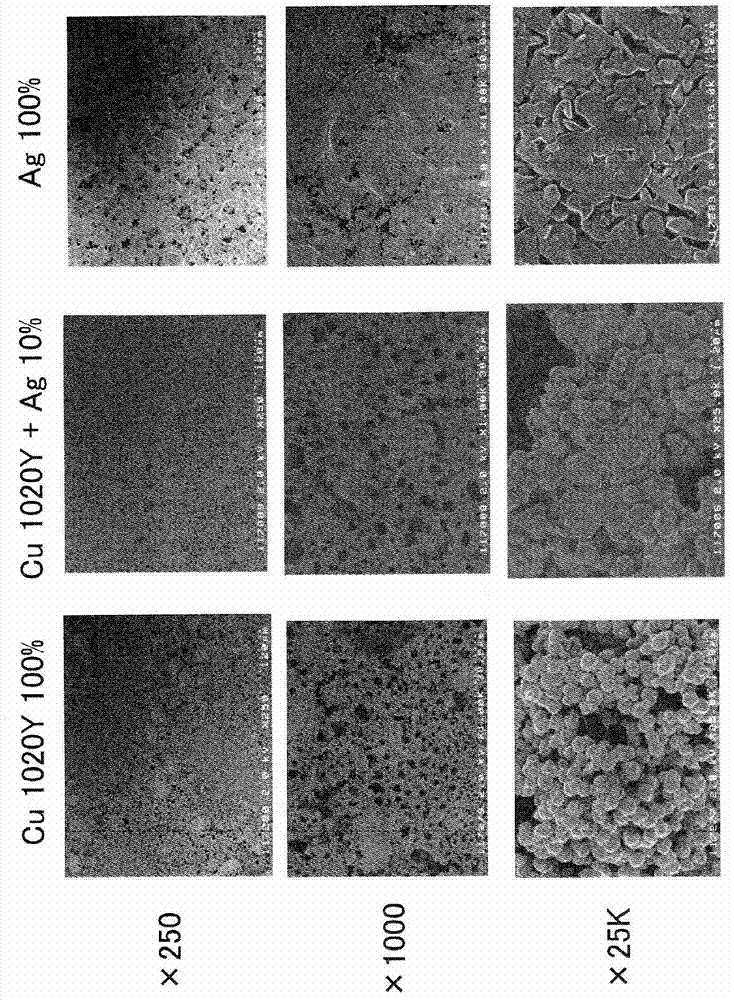

Embodiment 1

[0059] In a mixed aqueous solution (weight ratio ethylene glycol: glycerol: water = 70:15:15) of ethylene glycol and glycerin (a reagent manufactured by Kanto Chemical Co., Ltd.) as a reducing agent, dissolve the polyethylene group as a binder Pyrrolidone (manufactured by Nippon Shokubai Co., Ltd.) prepared a 40% by mass binder solution. 1.5 g of this solution was mixed with 0.5 g of the above-mentioned mixed aqueous solution, and 5.4 g of copper powder 1050Y (spherical shape, D50=716 nm) manufactured by Mitsui Metal Mining Co., Ltd. and N300 (flat shape (flat shape ( Thickness: 30nm), D50 = 470nm) 0.6g (copper particles: silver particles = 90:10), using the rotation and revolution vacuum mixer Awatori Rentaro ARV-310 (manufactured by Shinki Co., Ltd.) to mix well and make for printing paste (conductive pattern forming composition).

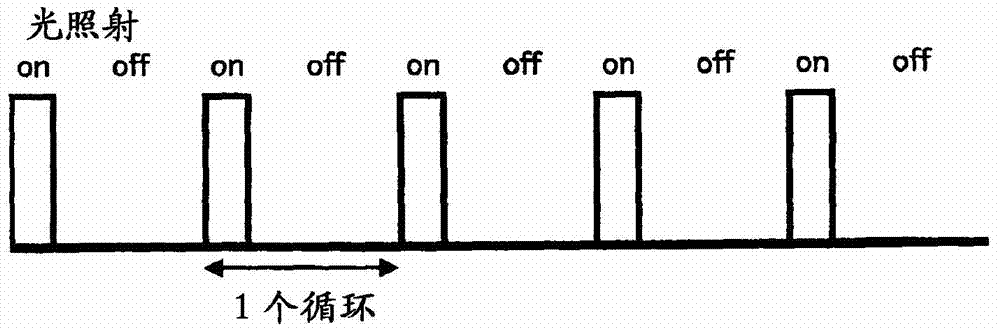

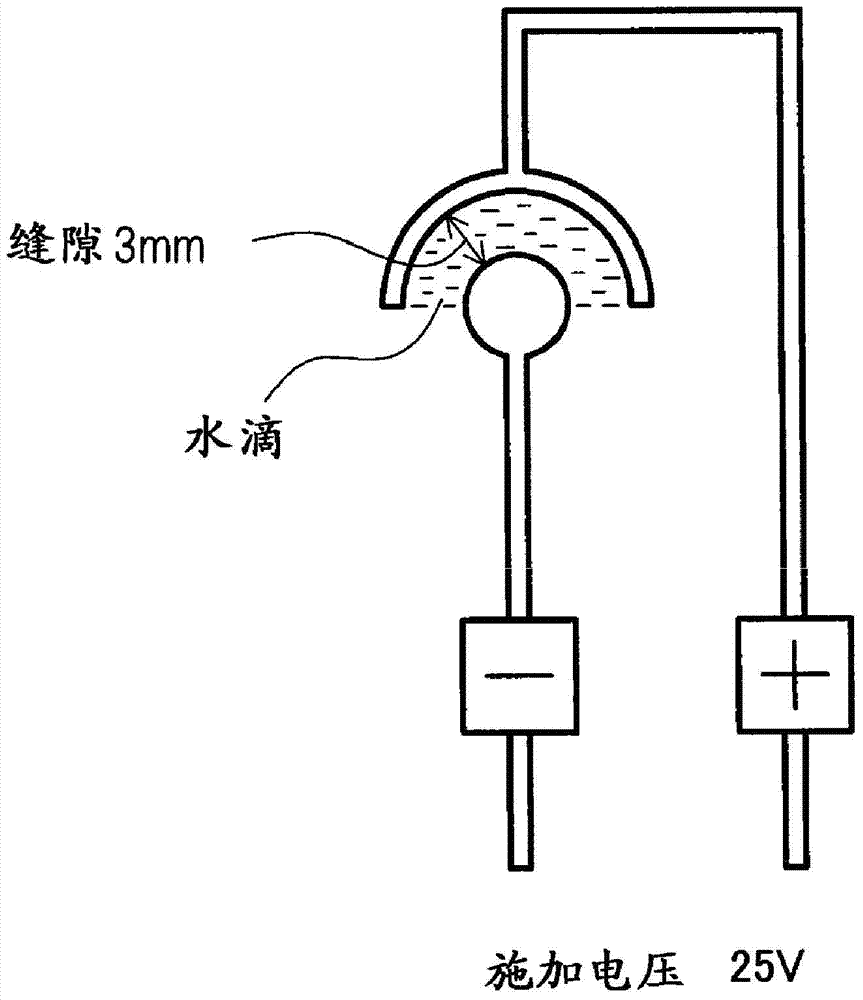

[0060] The obtained paste was screen-printed to print a 2 cm x 2 cm square pattern on a polyimide film (Capton 100V, manufactured by Toray Dupo...

Embodiment 2

[0062] Using 5.4 g of copper powder 1100Y (spherical shape, D50=1110 nm) manufactured by Mitsui Metal Mining Co., Ltd. and 0.6 g of N300 (flat shape (thickness: 30 nm), D50=470 nm) manufactured by Tokusen Industry Co., Ltd. as silver particles, and Example 1 A paste for printing was prepared in the same manner. The obtained paste was subjected to pattern printing and light irradiation in the same manner as in Example 1. The thickness of the formed conductive pattern was 23 μm.

Embodiment 3

[0064] Using 5.4 g of copper powder 1400Y (spherical, D50 = 5700 nm) manufactured by Mitsui Metal Mining Co., Ltd. and 0.6 g of N300 (flat shape (thickness: 30 nm), D50 = 470 nm) manufactured by Tokusen Industry Co., Ltd. as silver particles, and Example 1 A paste for printing was prepared in the same manner. The obtained paste was subjected to pattern printing and light irradiation in the same manner as in Example 1. The thickness of the formed conductive pattern was 26 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com