Circuit board structure and manufacturing method thereof

A manufacturing method and circuit board technology, which are applied in the directions of printed circuit manufacturing, laminated printed circuit boards, circuit covers, etc., to achieve the effect of omitting the pasting steps, reducing production costs, and avoiding cutting waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0056] see Figure 4 to Figure 8 , which is the first embodiment of the present invention. What needs to be explained first is that this embodiment corresponds to the relevant quantities and shapes mentioned in the accompanying drawings, and is only used to specifically illustrate the implementation of the present invention, so as to facilitate understanding of its content , not to limit the protection scope of the present invention.

[0057] This embodiment is a method for manufacturing a circuit board structure, including step a) to step e). The sequence of steps described below is only for understanding this embodiment, but the sequence of these steps is not limited. The various steps of the manufacturing method of the circuit board structure in this embodiment are roughly described as follows:

[0058] Step a): See Figure 4 As shown, a circuit board 1 is provided, and the circuit board 1 is preferably a flexible circuit board or a rigid-flex board in this embodiment, bu...

no. 2 example

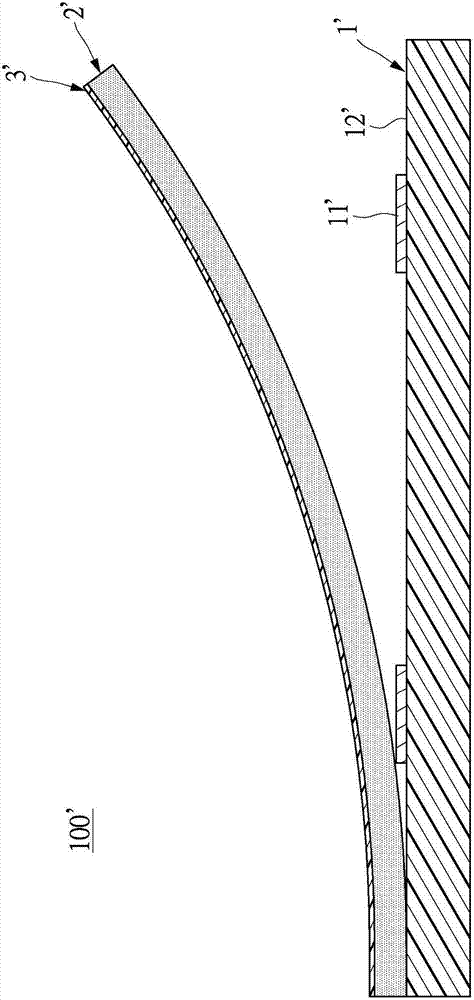

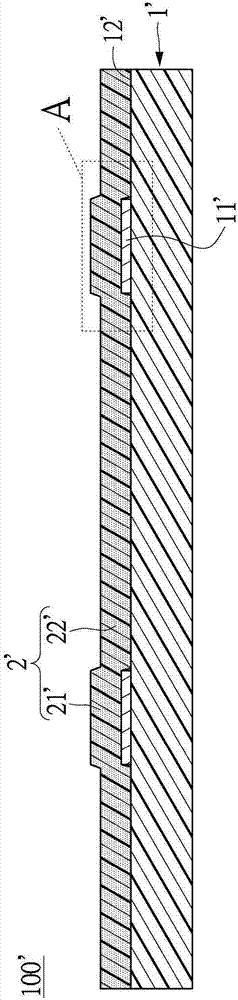

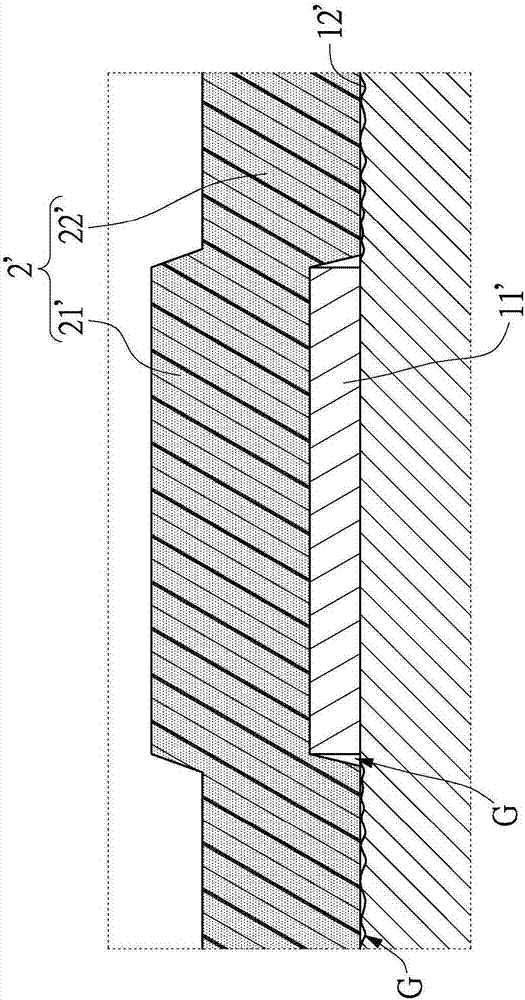

[0076] see Figure 10 to Figure 13 , which is the second embodiment of the present invention. This embodiment is similar to the above-mentioned first embodiment, and the same parts will not be repeated. The difference between the two mainly lies in the manufacturing method of the circuit board structure. The specific differences are as follows:

[0077] Step a): See Figure 10 As shown, a circuit board 1 is provided, and the circuit board 1 is preferably a flexible circuit board or a rigid-flex board in this embodiment, but it is not limited thereto. Wherein, the circuit board 1 has a first board surface 11 and a second board surface 12 on opposite sides, and the circuit board 1 includes at least one conductive circuit 13 arranged on the first board surface 11, the first The board surface 11 defines a predetermined area (not marked), and the conductive circuit 13 is at least partially located on the predetermined area.

[0078] Furthermore, the predetermined area of the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com