Bi-directional conduction electric-heating tube

An electric heating tube and tubular technology, which is applied in the field of bidirectional heat conduction electric heating pipes, can solve the problems of qualified rate risk, the structural design of electric heating elements cannot meet the overall development requirements of high power and small volume, and cannot bear the needs of high heat transfer, etc., to achieve life expectancy improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

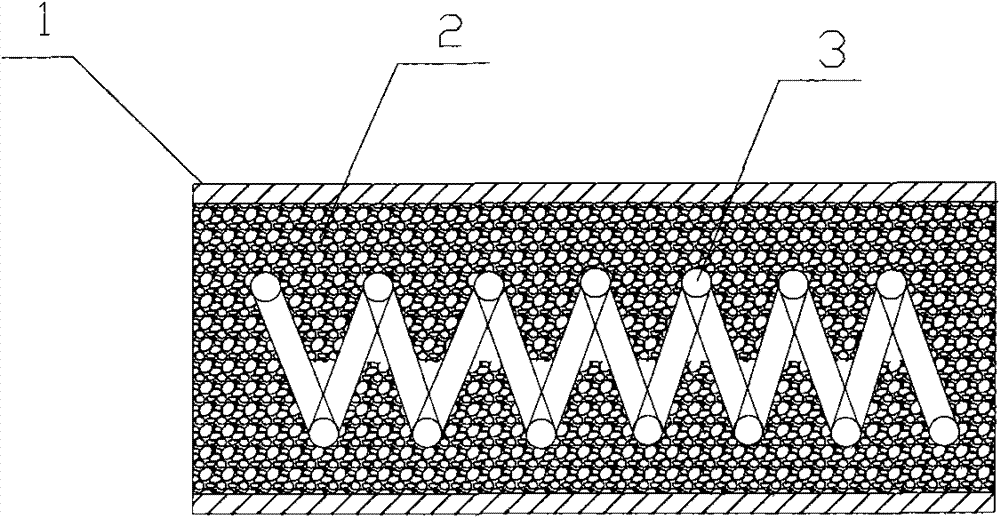

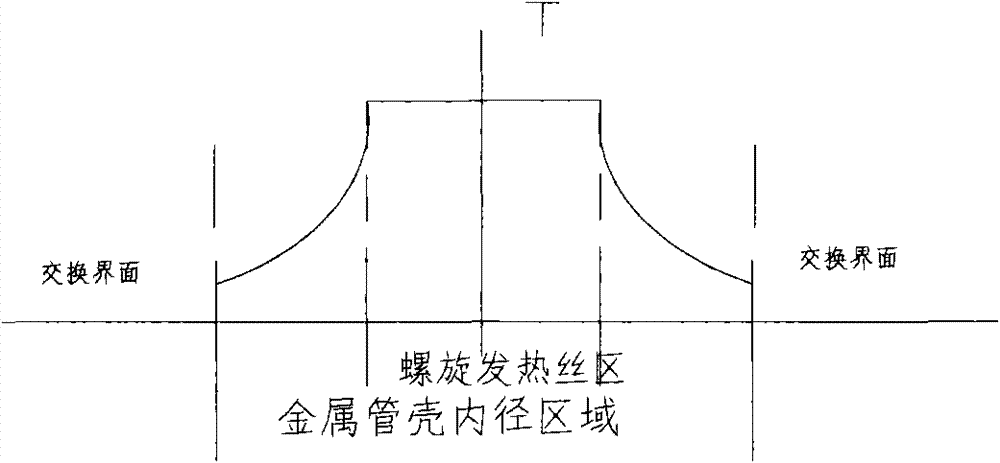

[0060] see image 3 When the working voltage is applied to the lead rod 6 shown in the figure, the heating wire 2 connected to the lead rod 6 generates heat, and the heat is transferred to the metal tubes 1 and 5 through the filling materials 3 and 4, so that they are respectively connected to the heated Heat exchange occurs in the medium.

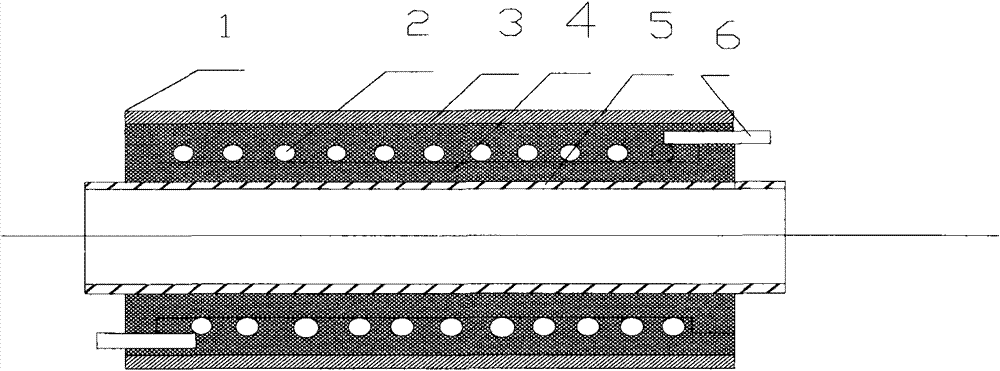

[0061] see Figure 5 ; The working principle of the device shown in the figure is introduced as follows: It is a schematic diagram of a multi-power product. Although the structure in the figure is an integral component, it can realize four different powers, that is, use the inner side alone The power of P1 can be obtained when the heating wire is 8, and the power obtained when the heating wire 4 is used alone is P2. If the heating wire 4 and 8 are connected in series, the power obtained is P3. Similarly, if the heating wire 4 and 8 are connected in parallel to obtain The power is P4. The principle is that the biggest difference from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com