Laser light source and lighting device

A laser light source and laser diode technology, applied in the field of lighting, can solve the problems of not fully utilizing the advantages of the fixed plate to transmit heat, the temperature of the fluorescent sheet is too high, and the conduction efficiency is low, so as to reduce heat accumulation, prolong the life of the fluorescent sheet, and speed up the The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

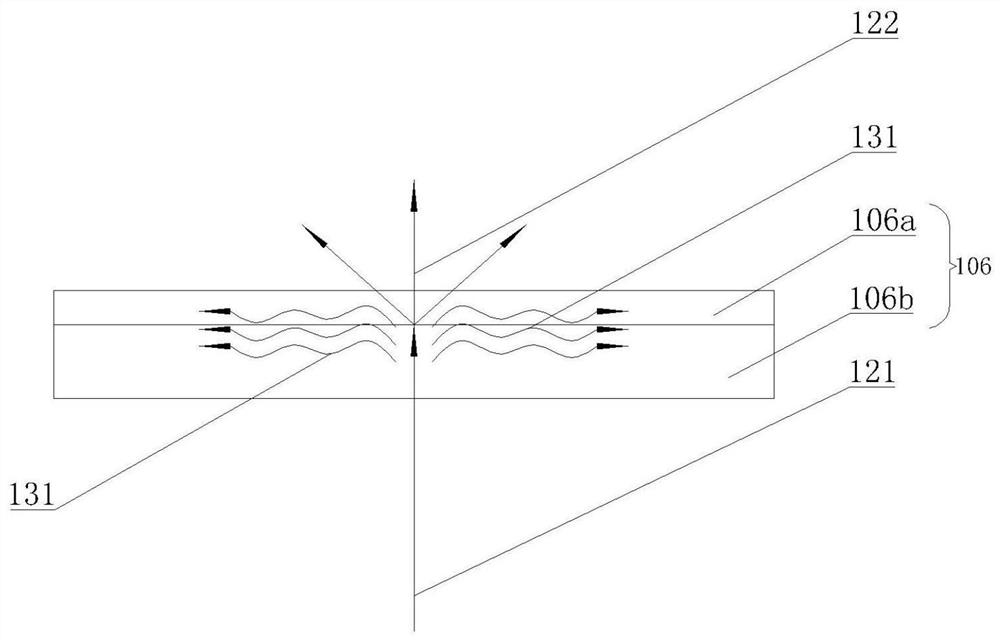

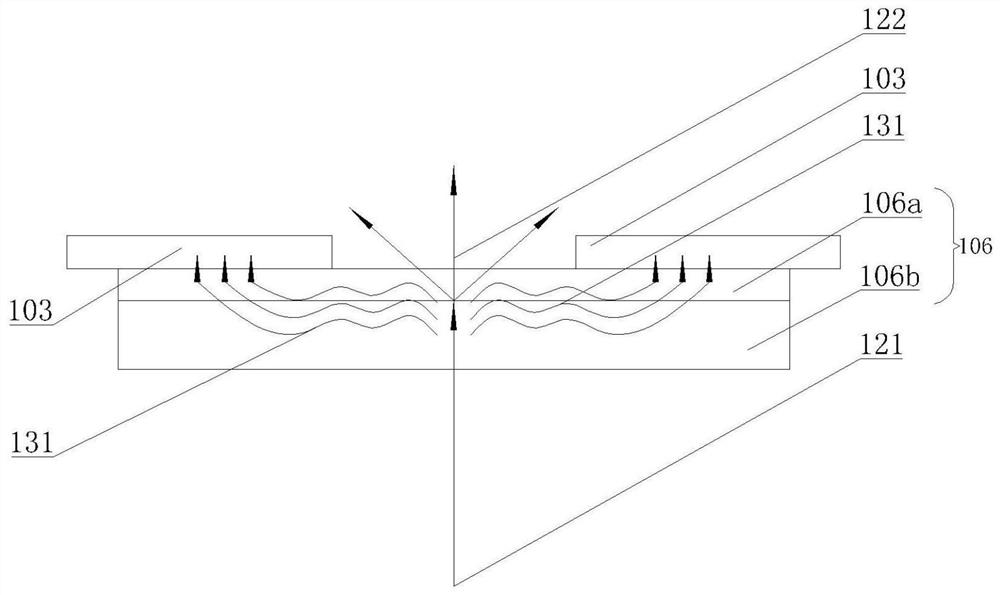

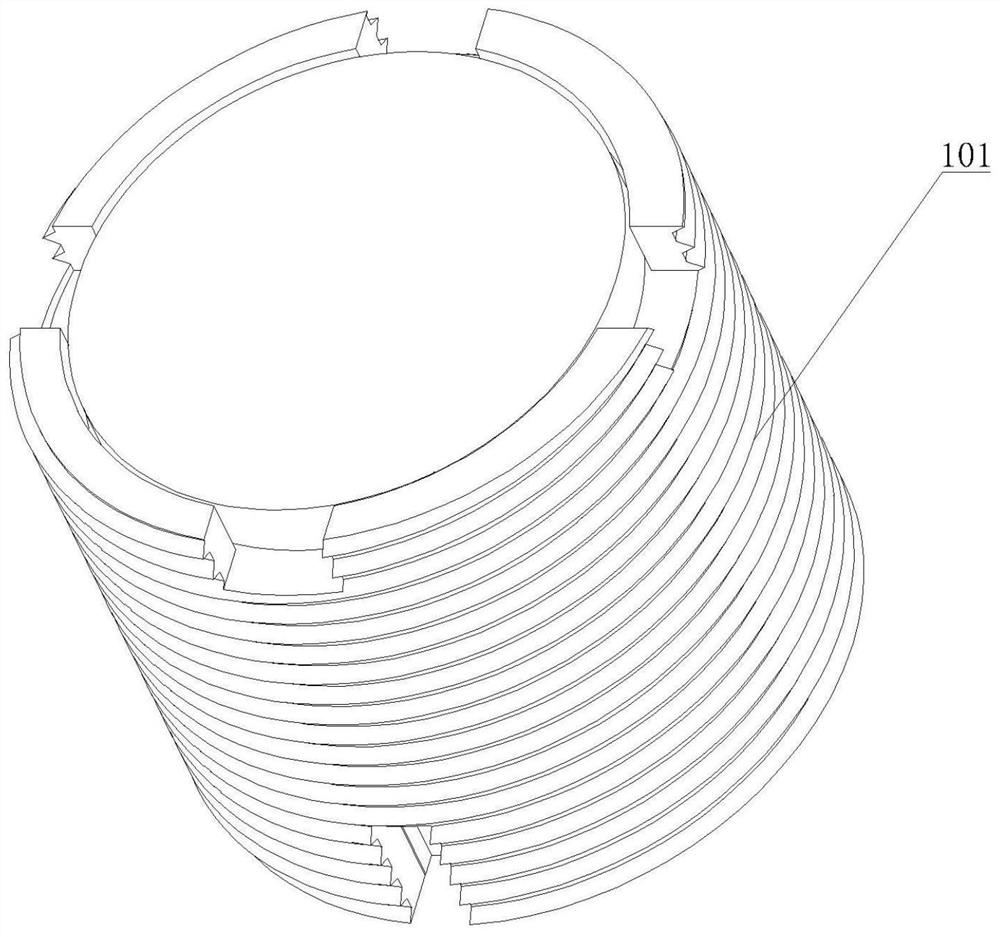

[0026] Such as Figure 3-7 As shown, a laser light source includes a laser diode emitting laser light 121 and a fluorescent sheet 106 excited by the laser diode. The fluorescent sheet 106 includes a transparent thermally conductive substrate 106b and a fluorescent material 106a covered on the surface of the substrate 106b. It also includes a fixing plate 102 and a fixing block 103 for fixing the fluorescent sheet 106. Since the fixing block 103 is used to transfer the heat 131 of the fluorescent sheet 106 to the fixing plate 102, the fixing block 103 needs to be connected with the fluorescent sheet 106 and the fixing plate 102. Therefore, the fixing block 103 is disposed on the fixing plate 102 . The fixed block 103 is in direct contact with the fixed plate 102, and the heat transfer speed is fast and the heat transfer efficiency is high; for example, preferably, the fixed block 103 and the fixed plate 102 are integrally formed, and there is no interface between the two at thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com