Lost pattern, method for producing lost pattern, and method for producing die using lost pattern

A manufacturing method and technology of metal molds, applied in the direction of manufacturing tools, forming tools, metal processing equipment, etc., can solve problems such as difficult operations, and achieve the effect of high shape accuracy and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

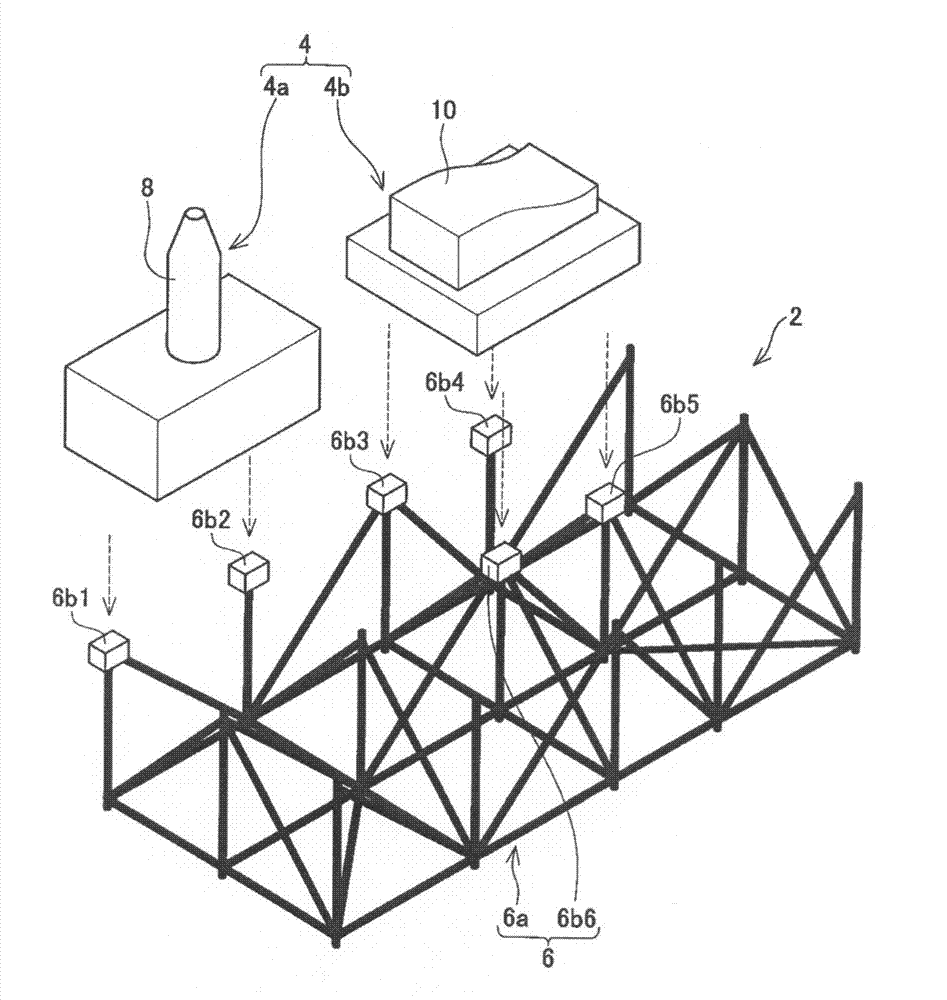

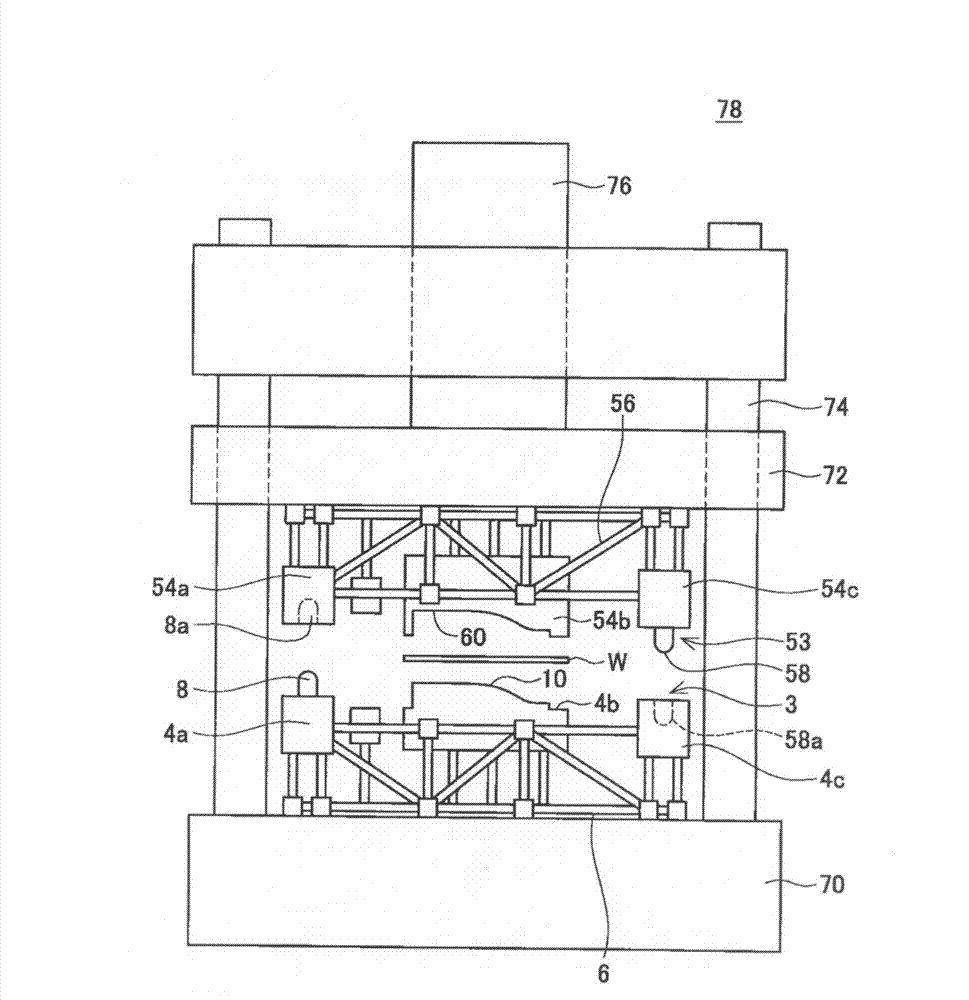

[0042] figure 1 An exploded perspective view showing part of the vanishing model 2 partially formed of the three-dimensional mesh structure 6 . Although in figure 1 In the figure, it shows the situation after the blocks 4a and 4b are detached from the three-dimensional mesh structure 6, but actually the blocks 4a and 4b are fixed on the three-dimensional mesh structure 6, and the relative positional relationship between the blocks 4a and 4b is fixed by the three-dimensional mesh structure 6. Positional relationship.

[0043] The vanishing model 2 is a model produced by cutting a foamed styrene block. The vanishing model 2 can be cut out from the foamed styrene block by using a machine tool that rotates the end mill and adjusts the relative positional relationship between the workpiece and the end mill to a commanded positional relationship.

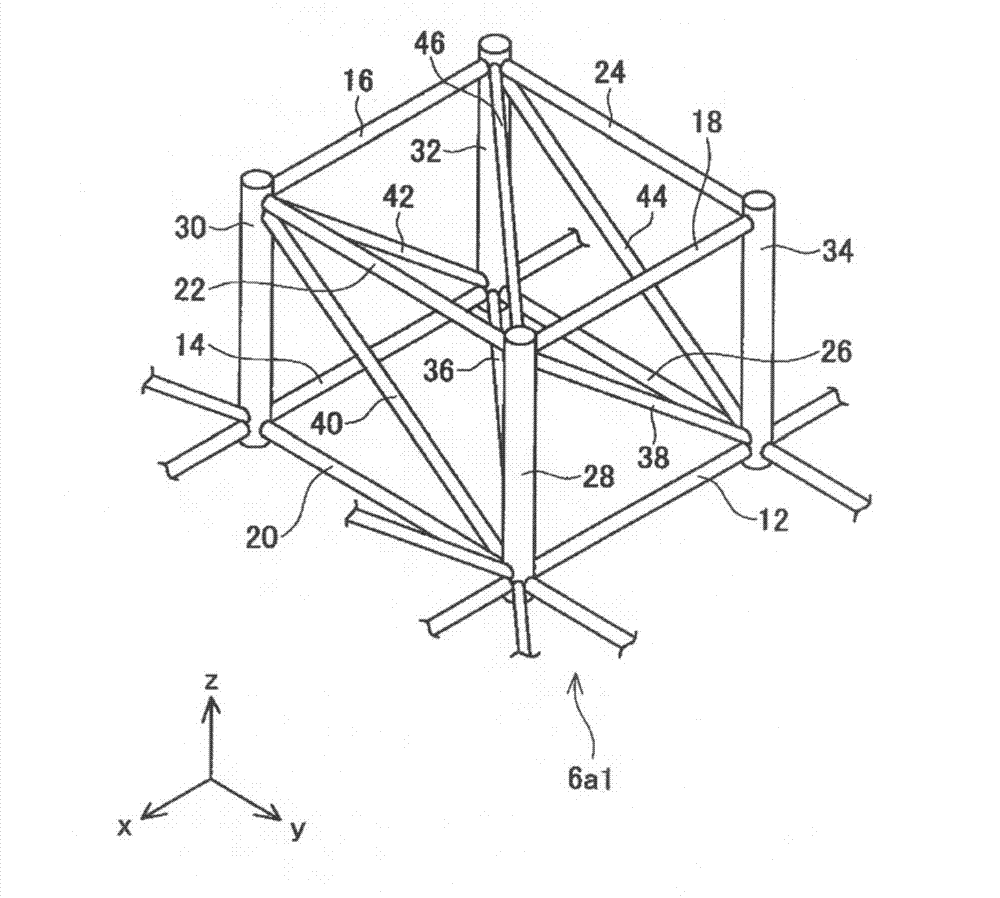

[0044] The three-dimensional mesh structure 6 is formed by a plurality of rod-shaped parts 6a, the ends of the rod-shaped parts 6a ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com