Torque distribution control method for a four-wheel drive motor vehicle and corresponding vehicle

A torque distribution, motor vehicle technology, applied in the direction of control devices, vehicle components, transportation and packaging, etc., can solve problems such as not provided, and achieve the effect of avoiding the danger of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

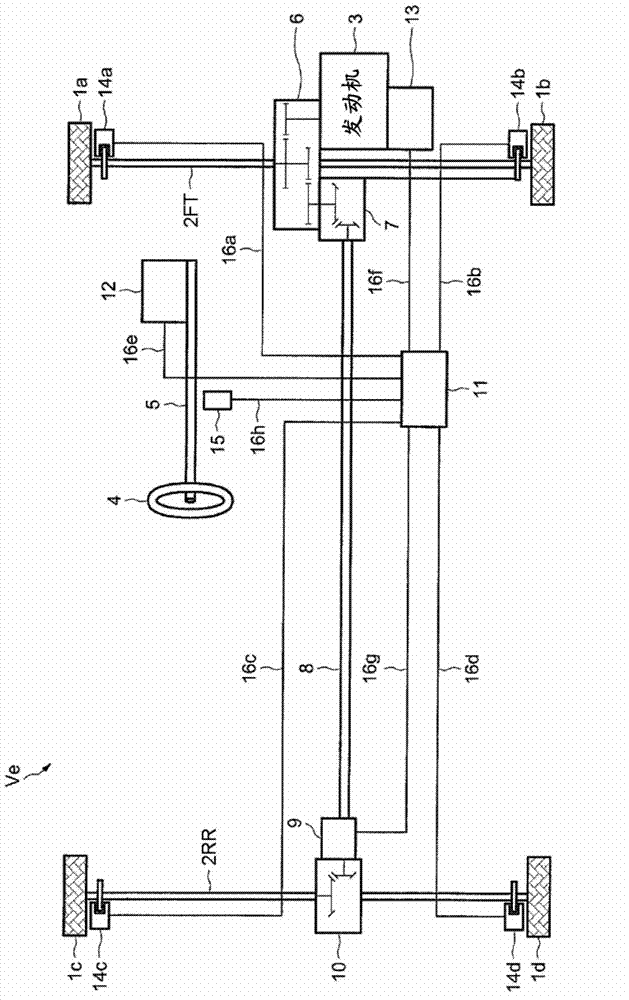

[0038] figure 1 The main components of a four-wheel drive motor vehicle Ve are schematically shown with permanent engine torque transmission to the front axle 2FT. This type of vehicle is selected as an example. The engine of the vehicle may be an internal combustion engine 3 , an electric motor or a hybrid combination. The persistent transmission of engine torque can be applied equally to the rear axle 2RR.

[0039] The vehicle includes four wheels 1a, 1b, 1c, 1d mounted on a front axle 2FT and a rear axle 2RR, respectively. The vehicle also includes a steering wheel 4 connected to a steering column 5 . The vehicle also includes a gearbox 6 that transmits torque from the engine 2 to a front axle 2FT and a front transfer case 7 . A transfer shaft 8 driven by this transfer case 7 is connected to a rear axle transfer case 10 through a coupling 9 in order to transmit torque from the transmission case 6 to the rear axle 2RR.

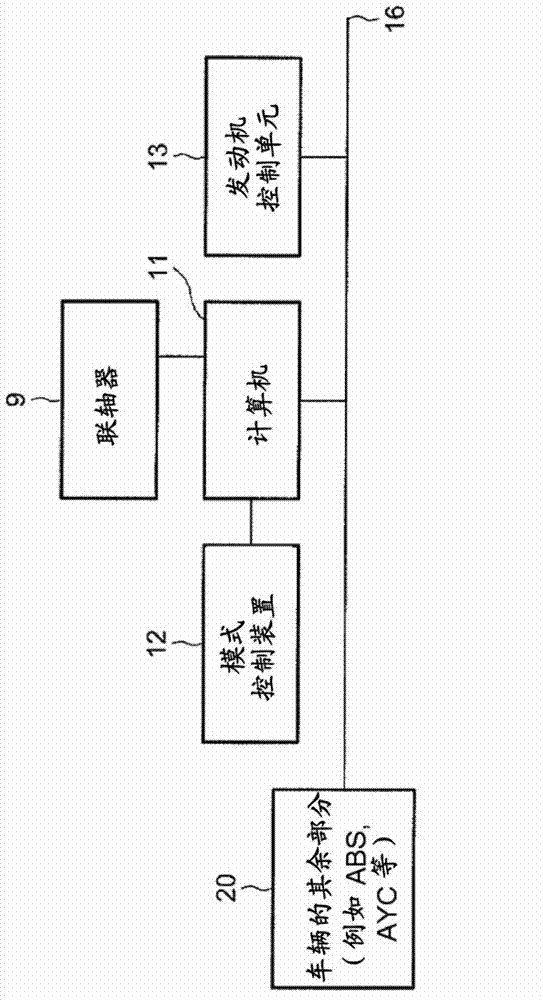

[0040] The vehicle also comprises a computer 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com