A motor automatic calibration method, device and controller

A technology of automatic calibration and motor temperature, applied in the estimation/correction of motor parameters, etc., can solve the problems of over-temperature danger, influence of fitting results, influence of data accuracy, etc., to avoid the effect of over-temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

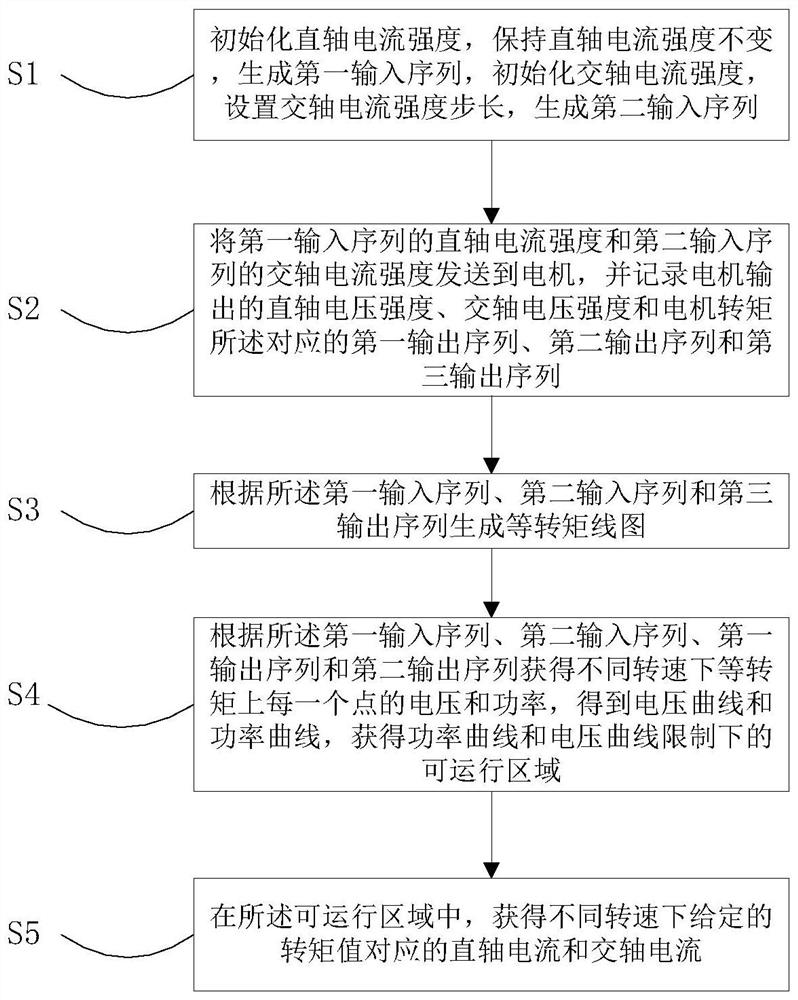

[0058] An embodiment of the present invention provides a motor automatic calibration method, such as figure 1 As shown, the method includes:

[0059] S1. Initialize the direct-axis current, keep the direct-axis current unchanged, generate the first input sequence, initialize the quadrature-axis current, set the step size of the quadrature-axis current, and generate the second input sequence.

[0060] S2. Send the direct-axis current of the first input sequence and the quadrature-axis current of the second input sequence to the motor, and record the corresponding first output sequence of the direct-axis voltage intensity, quadrature-axis voltage intensity and motor torque output by the motor , the second output sequence and the third output sequence.

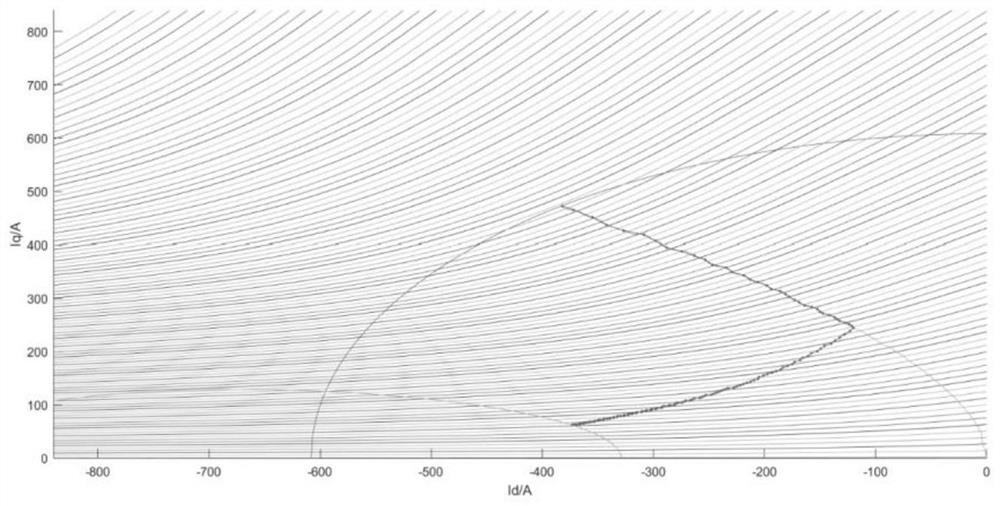

[0061] S3. Generate an isotorque diagram according to the first input sequence, the second input sequence and the third output sequence.

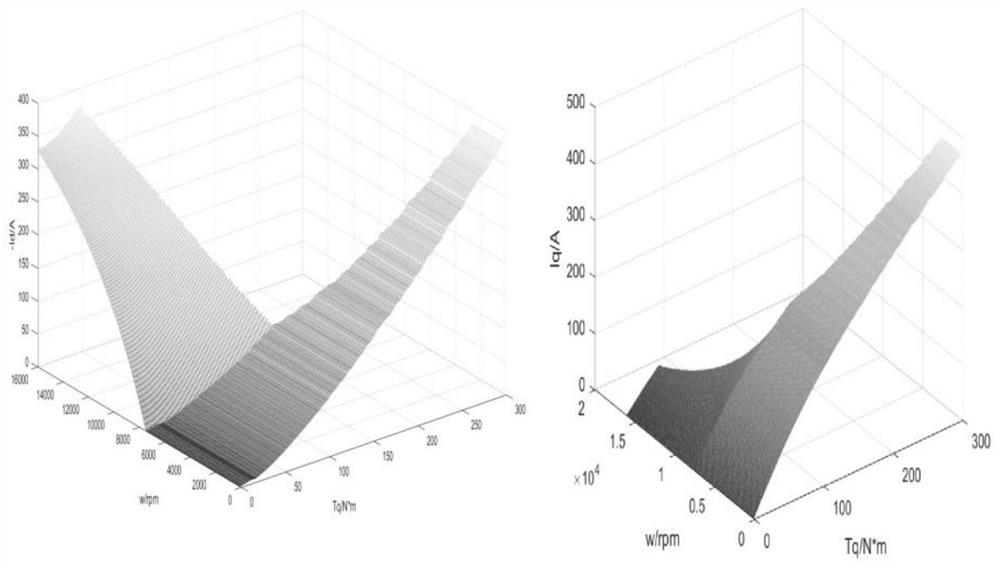

[0062] S4. According to the first input sequence, the second input sequence, the first o...

Embodiment 2

[0097] A feasible embodiment of the present invention provides an automatic motor calibration device. Specifically, such as Figure 4 As shown, the motor automatic calibration device includes: an initialization sequence acquisition module, a motor control module, a data processing module and a temperature detection module.

[0098] The initialization sequence acquisition module is used to initialize the direct axis current, initialize the quadrature axis current and set the step size of the quadrature axis current, and obtain the initialized direct axis current list and the initialized quadrature axis current list;

[0099] The motor control module is used to obtain and record the motor torque, direct-axis voltage intensity and quadrature-axis voltage intensity according to the initialized direct-axis current list and the initialized quadrature-axis current list;

[0100] The data processing module is used to perform data processing on the direct axis current, quadrature axis...

Embodiment 3

[0138] An embodiment of the present invention provides a controller, which includes the above-mentioned automatic calibration device for a motor. A computer-readable storage medium is included in the controller, and at least one instruction, at least one section of program, code set or instruction set are stored in the storage medium, and the at least one instruction, the at least one section of program, the code The set or instruction set is loaded and executed by the processor to realize the above-mentioned automatic calibration method of the motor.

[0139] The controller is used to obtain the direct-axis current of the first input sequence and the quadrature-axis current of the second input sequence, and record the motor torque, the direct-axis voltage intensity and the quadrature-axis voltage intensity corresponding to the output of the first output sequence, the second Second output sequence and third output sequence.

[0140] The controller can also obtain the isotorqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com