Segmented elastomeric vibration mount with edge control

An elastic layer and flange technology, applied in the field of segmented elastic vibration supports, can solve problems such as support failure, and achieve the effect of enhancing durability and bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Example embodiments will now be described more fully with reference to the accompanying drawings.

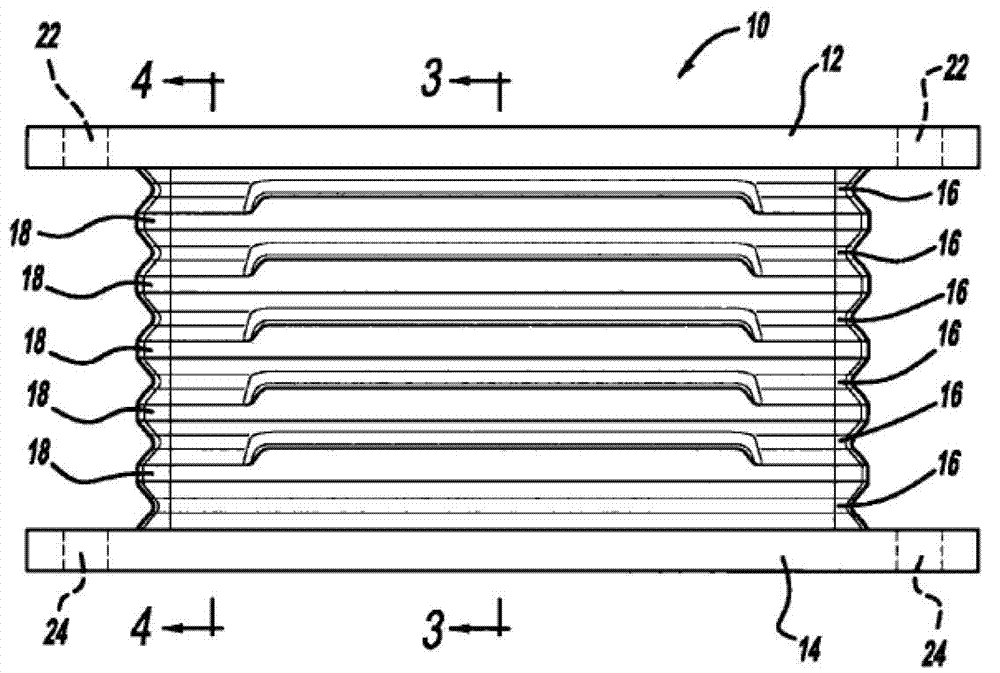

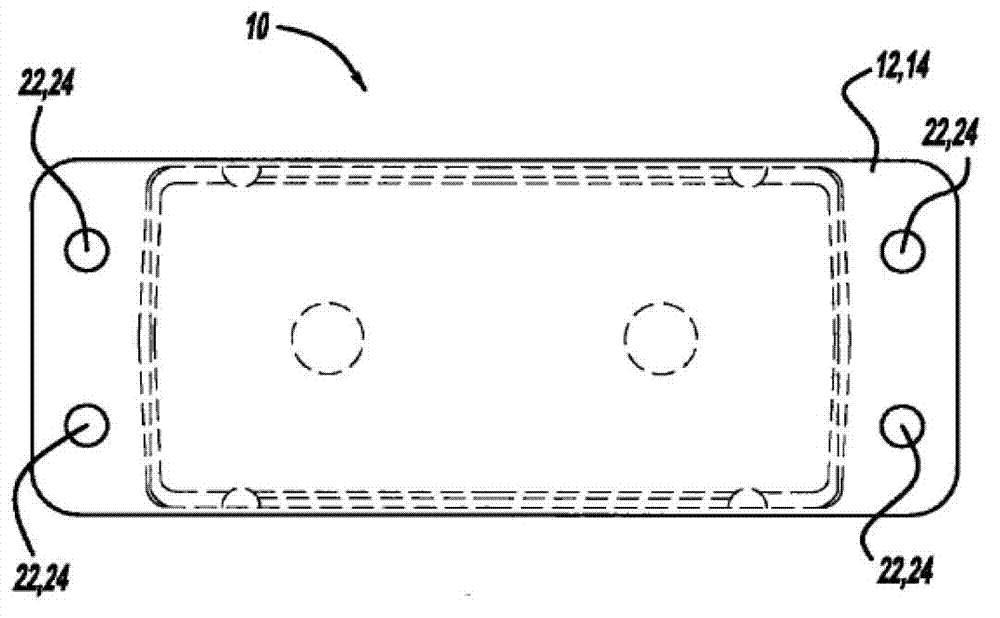

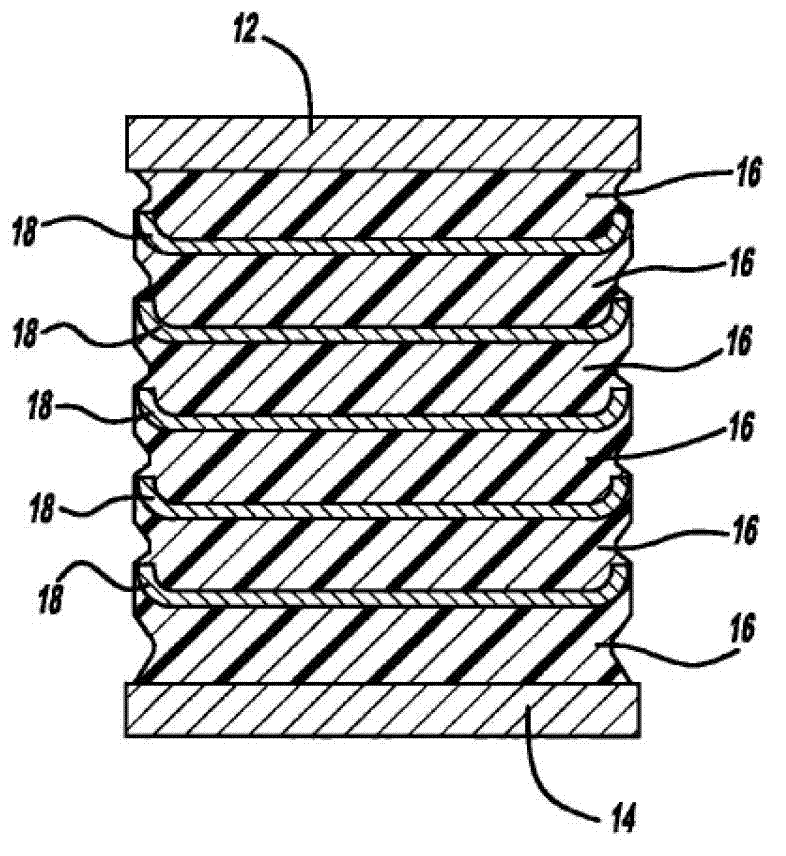

[0019] see Figure 1 to Figure 4 , a bracket assembly according to the present disclosure is illustrated and generally indicated by the reference numeral 10 . The bracket assembly 10 includes a first mounting plate 12 , a second mounting plate 14 , a plurality of elastic layers 16 and a plurality of spacers 18 .

[0020] The first mounting plate 12 is a generally rectangular plate having a plurality of mounting holes 22 extending through the first mounting plate 12 . The bracket assembly 10 is designed to be placed between two components and a plurality of mounting holes 22 are provided to receive suitable fasteners to attach the first mounting plate 12 to one of the two components. The second mounting plate 14 is a generally rectangular plate having a plurality of mounting holes 24 extending through the second mounting plate 14 . A plurality of mounting holes 24 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com