Solar cell array

A technology of solar cells and arrays, applied in the field of solar cell arrays, which can solve problems such as excessive construction hours and raw materials, and the inability to arrange solar cell modules beautifully

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

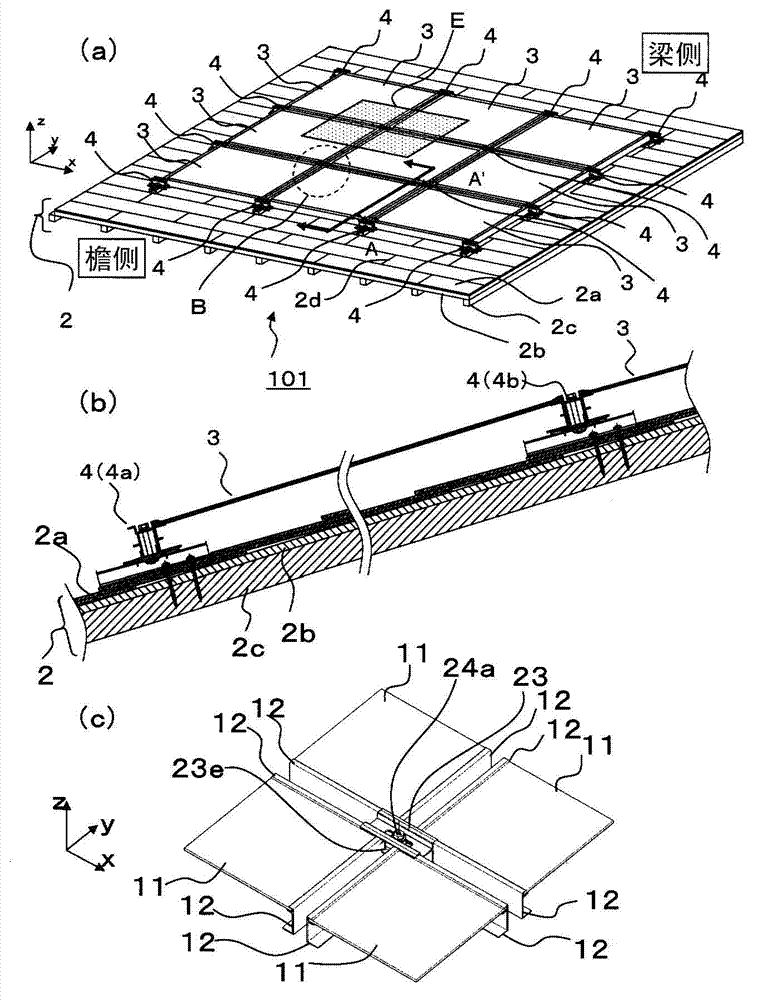

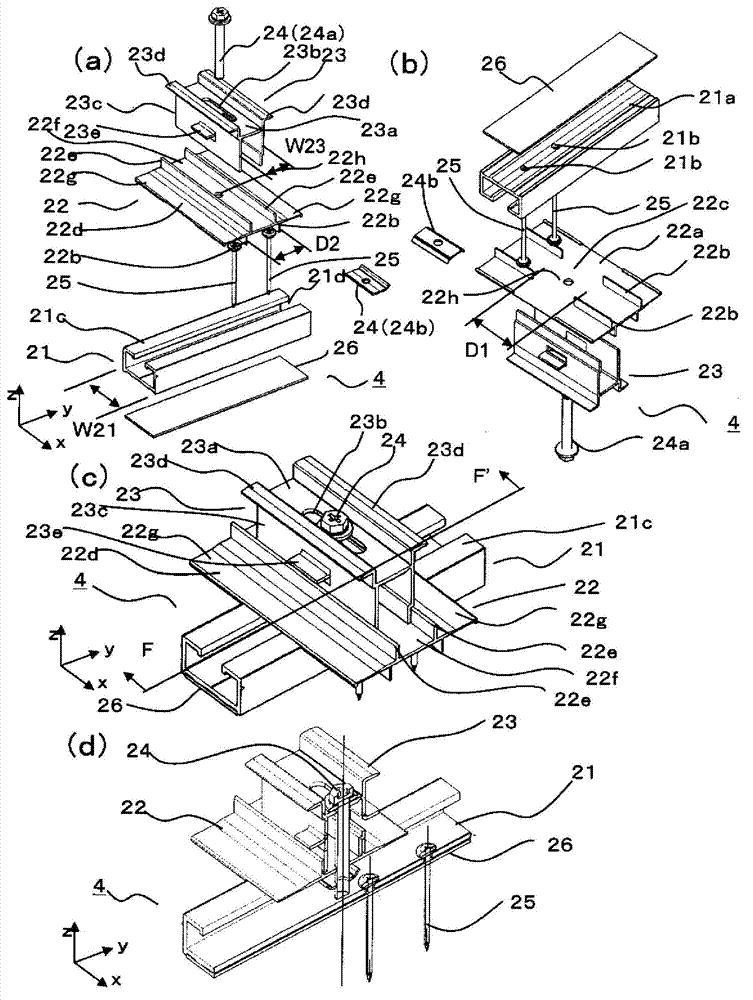

[0026] Such as figure 1 As shown in (a) and (b), the solar cell array 101 has a plurality of solar cell modules 3 and mounting members 4 . Such a solar cell array 101 is fixed to the base 2 (roof surface) including the roof panel 2a, the roof panel 2b, and the rafters 2c. In addition, the plurality of solar cell modules 3 are arranged so as not to overlap with each other with the back surface thereof as the lower side. In this embodiment, if figure 1 As shown in (a), a plurality of solar cell modules 3 are arranged along two directions, the Y direction which is the direction in which the inclined surface 2 is inclined, and the X direction perpendicular to the Y direction.

[0027]

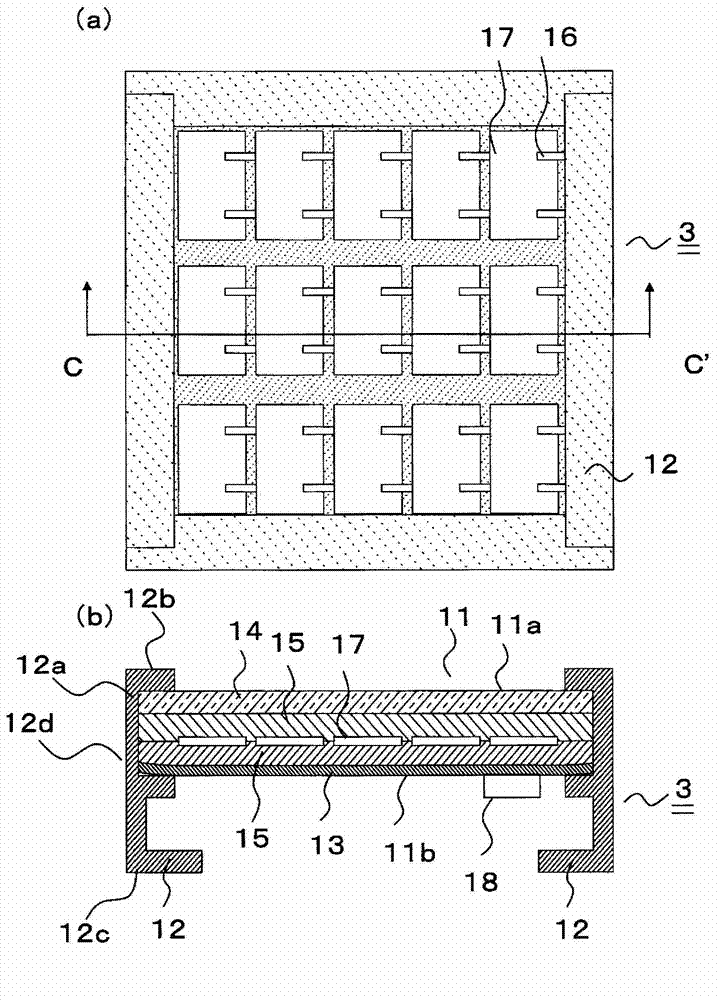

[0028] Such as figure 2 As shown, the solar cell module 3 has a solar cell panel 11 and a frame 12 .

[0029] Such as figure 2 As shown in (b), the solar cell panel 11 has a light-receiving surface 11a (one main surface of the light-transmitting substrate 14) that mainly receives light, an...

no. 2 approach

[0094] Next, use Figure 8 to Figure 10 , the solar cell array 201 of the second embodiment will be described in detail. It should be noted that description of the same configuration as that of the first embodiment will be omitted.

[0095]

[0096] Such as Figure 8 As shown, the solar cell array 201 of this embodiment further includes the eaves side member 5 for fixing the eaves side frame 12e of the solar cell module 3 arranged at the lowermost part in the inclined Y direction.

[0097] It should be noted that, in this embodiment, if Figure 8 As shown, hereinafter, the inclined direction of the base 2 is referred to as the Y direction, the direction normal to the base 2 is referred to as the Z direction, and the direction perpendicular to the Y direction and the Z direction is referred to as the X direction. In addition, among the solar battery modules 3 adjacent along the Y direction, the solar battery module located at the bottom (most on the front side of the eaves...

no. 3 approach

[0132] Next, use Figure 11 (a) and (b) illustrate the solar cell array 301 of the third embodiment.

[0133] Such as Figure 11 As shown in (a), the solar cell array 301 of the third embodiment is different from the solar cell array 201 of the second embodiment in the structure of the protective member 33 .

[0134] In this embodiment, the cross section of the hollow portion 33c of the protective member 33 cut along the direction perpendicular to the longitudinal direction of the track groove 33a is a quadrangular closed cross section.

[0135] In this way, the torsional rigidity is approximately doubled compared to the case of a hollow triangular cross-section having approximately the same size. Thereby, the strength of the eaves front side of the solar cell array 301 can be greatly improved.

[0136] In addition, in order to improve appearance, the hollow part 23c may be the cross-sectional shape of the trapezoid which has a hypotenuse at the front side of the hollow par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com