Pressure-controllable high-pressure hydration reaction device

A high-pressure hydration and reaction device technology, which is applied to chemical/physical/physical-chemical fixed reactors, pressure vessels used in chemical processes, etc., can solve problems such as safety, high pressure in the kettle, and uncontrollable pressure, etc., to achieve The effect of improving efficiency and safety and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

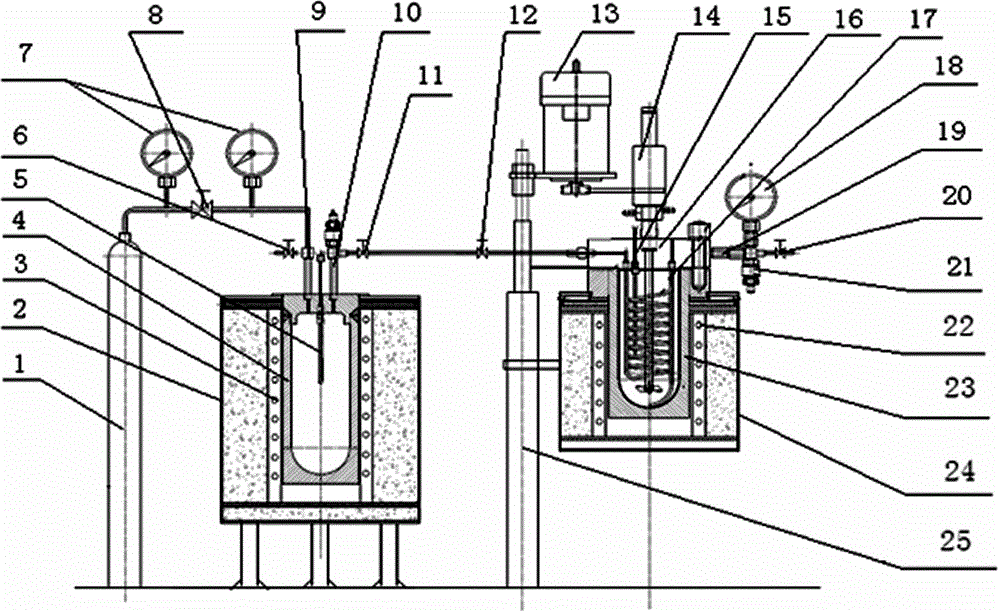

[0017] As shown in the figure, the pressure-controllable high-pressure hydration reaction device includes a compressed gas storage tank 1, a booster tank 2 and a high-pressure reactor 24; the gas outlet of the compressed gas storage tank 1 and the booster gas inlet of the booster tank 2 9 communicates; the pressurized gas outlet 10 of the pressurized tank 2 communicates with the gas inlet of the high-pressure reactor 24.

[0018] The high-pressure reaction kettle 24 of the present invention comprises a magnetic stirrer, a pressure-resistant reaction tank body 23, a cooling pipe 17 and a reactor heating furnace wire 22; the cooling pipe 17 is located in the pressure-resistant reaction tank body 23; the magnetic stirring The working end of the device is put into the cooling pipe 17; the heating furnace wire 22 of the heating reactor is fixedly arranged on the outer periphery of the pressure-resistant reaction tank body 23.

[0019] The pressurized tank 2 of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com