Laser head height adjusting device and method based on CCD (charge coupled device) vision

A height adjustment device and height adjustment technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of decreased welding or cutting accuracy, differences, changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

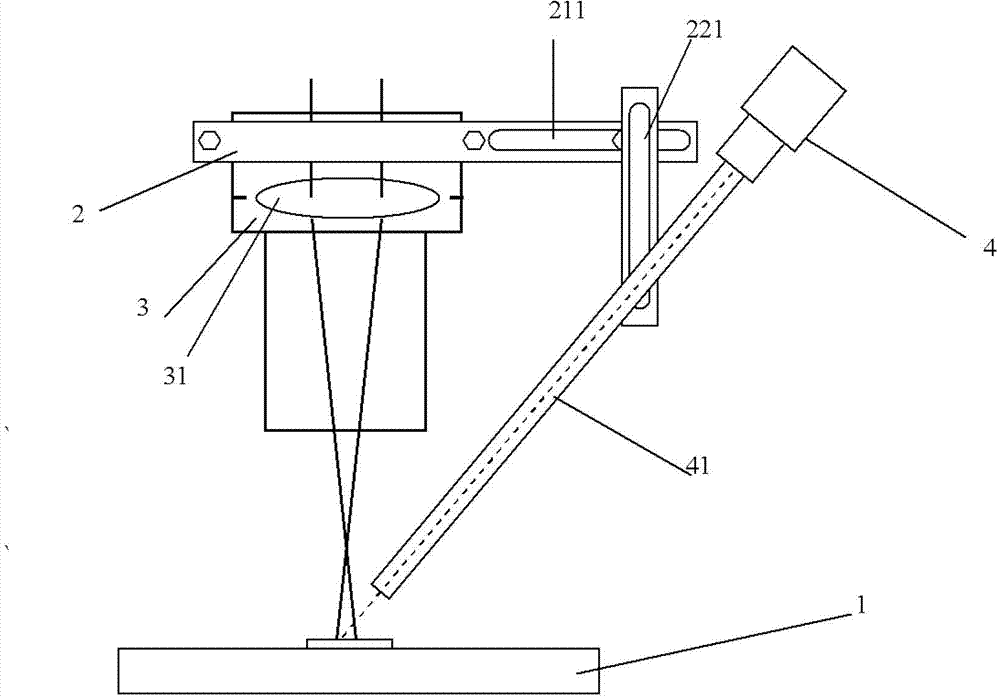

[0019] see figure 1 As shown, the present invention provides a kind of laser head height adjustment device based on CCD vision, comprising:

[0020] A processing platform 1;

[0021] A clamping device 2, which is located above the processing platform 1, the clamping device 2 includes a transverse clamping connection part 21 and a longitudinal clamping connection part 22, and the horizontal clamping connection part 21 and the longitudinal clamping connection part 22 are pivoted to each other Then, there is a transverse sliding groove 211 on the transverse clamping connection part 21 of the clamping device 2, which facilitates the sliding of the longitudinal clamping connection part 22 of the clamping device 2, and there is a longitudinal clamping connection part 22 on the clamping device 2 The longitudinal chute 221 is convenient for the CCD camera 4 pivotally connected to the longitudinal clamping connection part 22 of the clamping device 2 to slide and adjust the angle;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com