Vacuum adsorbing system for clamping and fixing thin plate during milling and use method thereof

A vacuum adsorption system, clamping and fixing technology, applied in the field of mechanical processing, to improve processing quality, solve clamping deformation, and improve the effect of milling processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

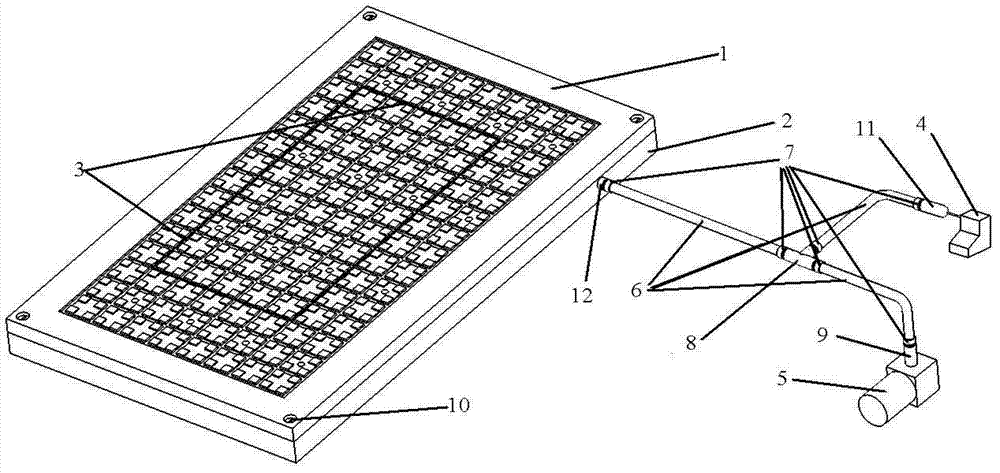

[0039] 1) see figure 1, the present invention is a vacuum adsorption system for clamping and fixing thin plate milling, including a vacuum platform 1, a base 2, a rubber sealing strip 3, pipelines, a digital vacuum gauge 4, a vacuum pump 5 and other parts. The position connection relationship between them is: the vacuum platform 1 is located on the base 2, the rubber sealing strip 3 is placed in the sealing groove on the base 2 and the vacuum platform 1, and the pipeline is composed of a threaded gas nozzle 12, a PTFE tube 6, and a ferrule 7. A three-way joint 8 and a threaded connector 9 are used to connect the base 2, the digital display vacuum gauge 4 and the vacuum pump 5.

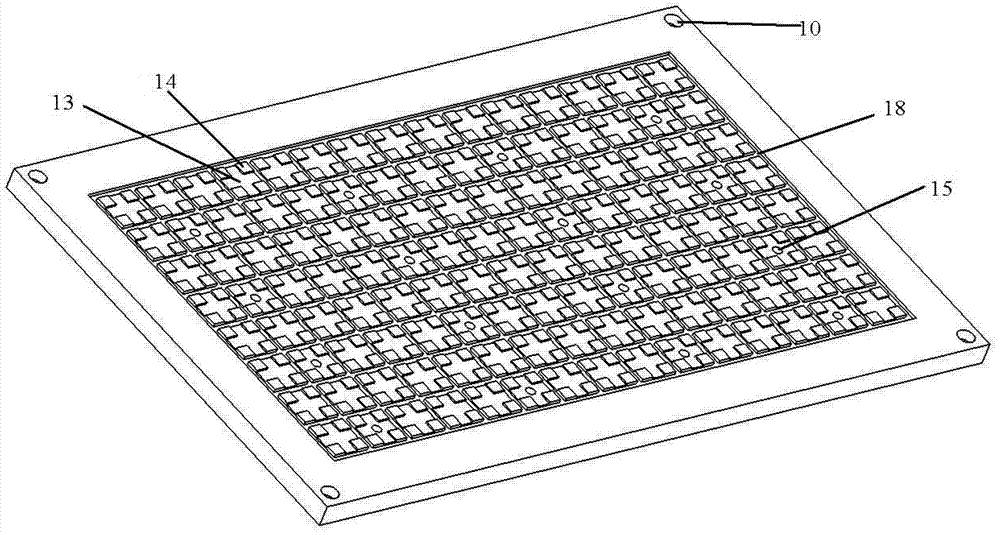

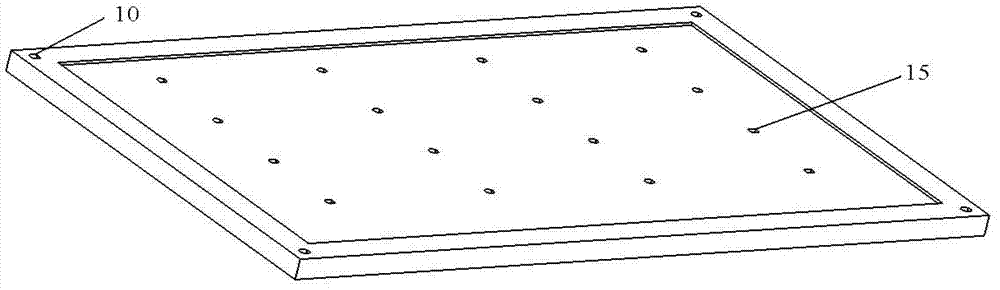

[0040] The vacuum platform 1 is processed from a thick aluminum plate, such as figure 2 Material shown is 6061-T6. The overall shape of the vacuum platform 1 is an inverted concave shape, which is convenient for installation and positioning with the base 2 (convex shape). The schematic diagram of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com