Release air-blowing device of flexible rubber mould

A blowing device and mold technology, which is applied in the field of release blowing devices for soft rubber molds, can solve problems such as product strain, poor release, deformation, etc., and achieve the goal of improving automation and stability, and improving quality and pass rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

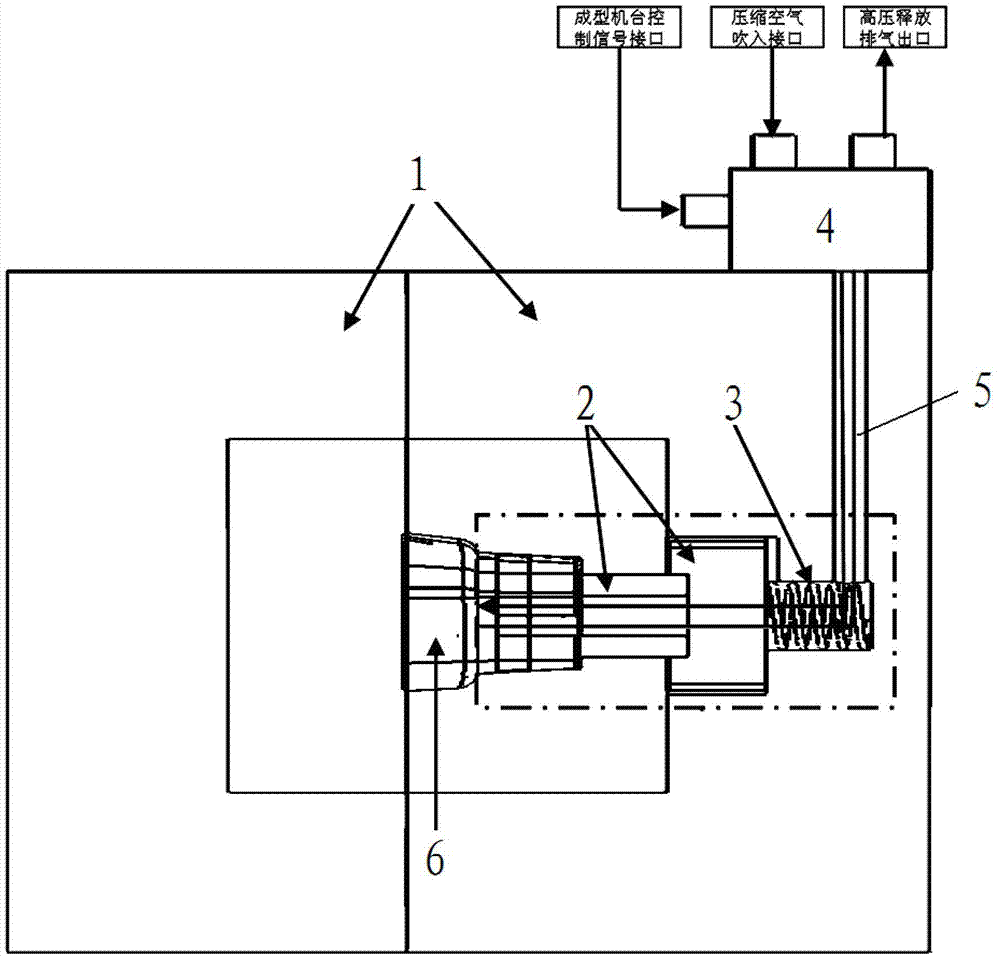

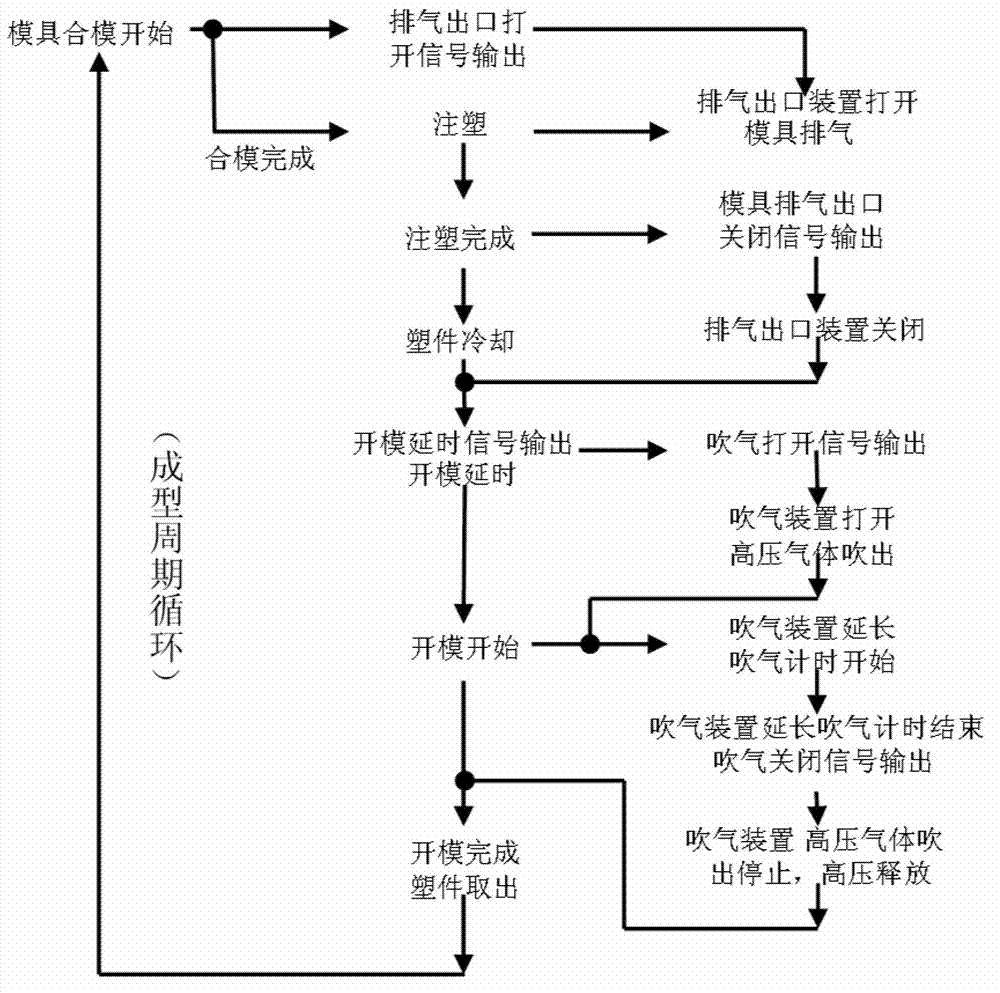

[0013] Such as figure 1 As shown, a soft rubber mold release blowing device includes compressed air blowing equipment, insert 2, spring 3 and conversion controller 4, insert 2 inside the mold 1 that is prone to poor release, and insert An opening is provided behind the mold core of the side mold 1, the insert 2 can be inserted into the opening, a spring 3 is connected to the rear end of the insert 2, a conversion controller 4 is arranged on the side mold 1, and the insert 2 can be inserted into the opening. The conversion controller 4 is connected with the gas pipeline 5 in the side mold, and the gas pipeline 5 is facing the connection between the opening and the inlet 2 , and the inlet 2 and the spring 3 are arranged in the gas pipeline 5 . The conversion controller 4 is also connected with the compressed air blowing equipment, and a high-pressure release / exhaust por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com