Developing machine

A developing machine and time-delay relay technology, which is applied in the field of developing machines, can solve the problems of high cost, remaining drops, expensive nozzles, etc., and achieve the effects of improved quality and pass rate, low cost, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical scheme of the utility model is described in detail below in conjunction with specific embodiments and accompanying drawings.

[0025] Under normal circumstances, the developing machine sprays the developer first and then the rinse solution or sprays out at the same time. The time of the two is adjustable, and the liquid can only be sprayed out within the specified time. If it exceeds the specified time, it is defined as residual drops.

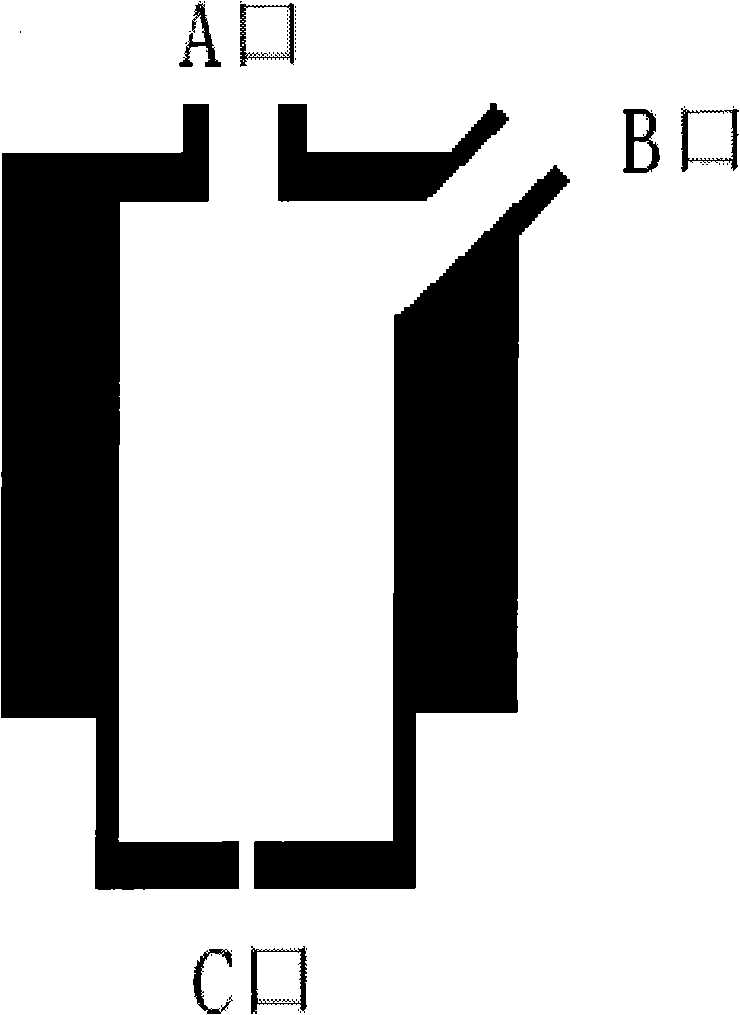

[0026] At least two connection holes and one nozzle are arranged on the nozzle of the developing machine. Such as figure 1 As shown, the overall shape of the nozzle is a long cylinder, the upper part is slightly larger than the lower part, and the A port is a connecting hole, that is, the liquid inlet, which is a liquid inlet pipe with a diameter of about 4mm; the B port is a connecting hole, That is, the air inlet, which is also 4mm in diameter; the C port is a nozzle, which is a very narrow and long port with a width of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com