Coating working gas constant-temperature heating device

A constant temperature heating and working gas technology, which is applied in the field of auxiliary equipment for glass coating, can solve problems affecting the quality of the coated glass film layer, and achieve the effects of improving quality and pass rate, uniformity and penetration, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

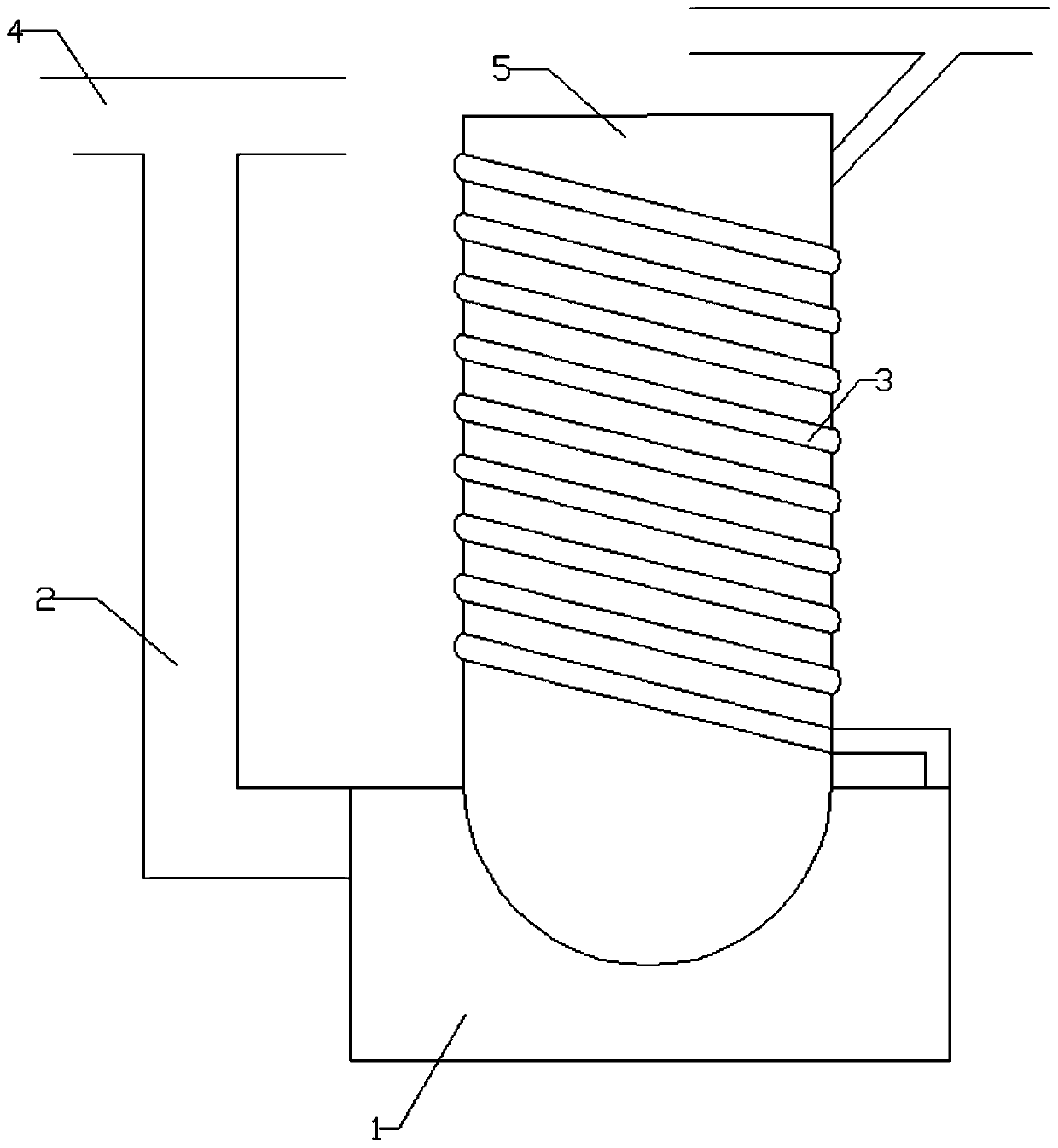

[0012] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

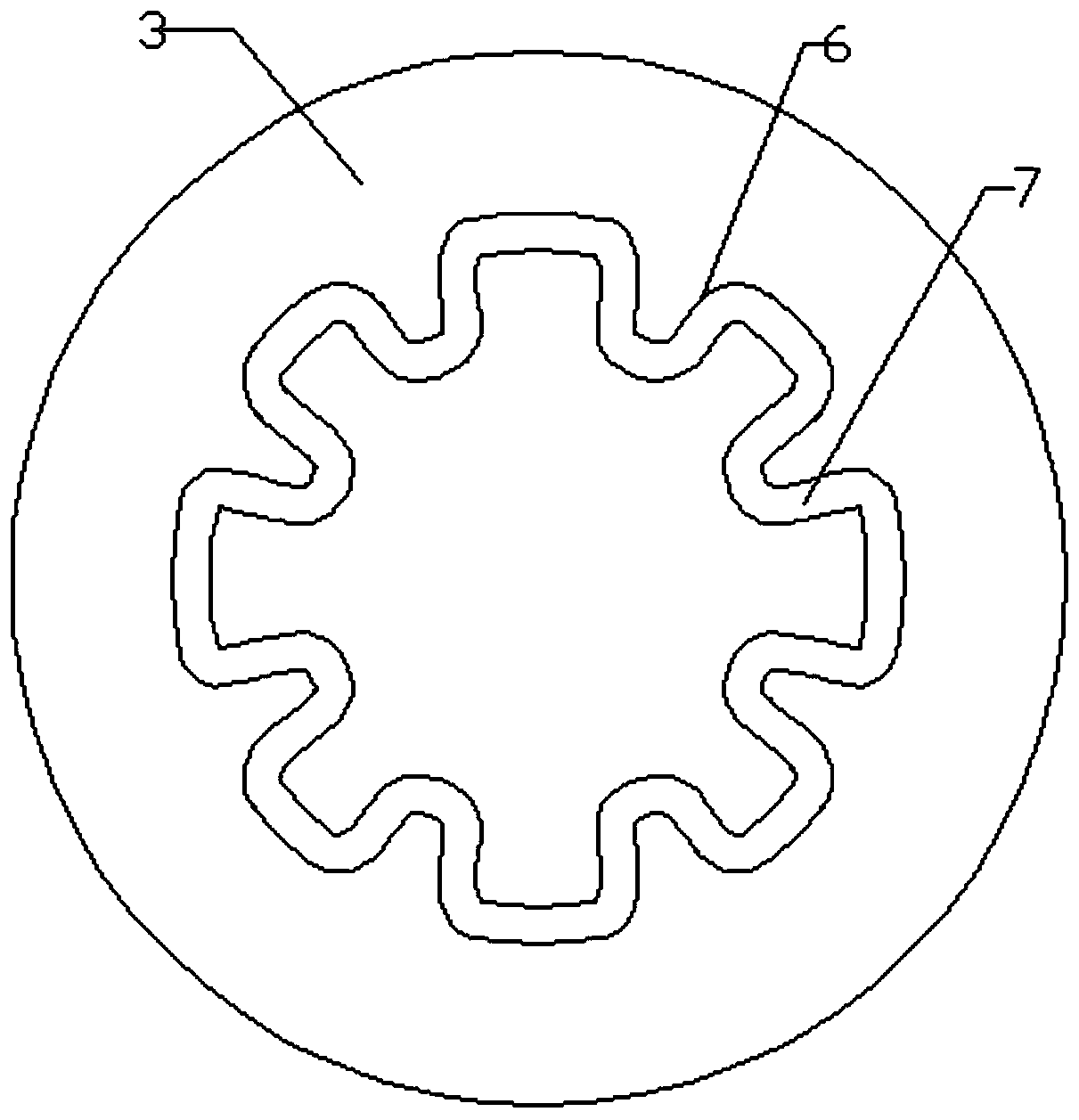

[0013] The present invention provides a coating working gas constant temperature heating device, which is arranged between the coating chamber and the gas cylinder 5, and includes a heat exchanger 1, a connecting water pipe 2 and a thin copper tube 3, and the heat exchanger 1 passes through the connecting water pipe 2 It is connected with the water outlet pipe 4 of the coating chamber, and the heat exchanger 1 is arranged under the gas cylinder 5. One end of the copper thin tube 3 is connected with the heat exchanger 1, and the other end is connected with the cooling room through the connecting water pipe 2. 3 is wound on the cylinder 5.

[0014] The principle of the new coating working gas constant temperature heating device is that the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com