Copper wire drawing and annealing method

A copper wire and annealing technology, which is applied in the direction of furnace type, furnace, heat treatment furnace, etc., can solve the problems of copper wire surface oxidation, steam and coolant leakage, low copper rate, etc., so as to improve the pass rate and quality, and prevent product oxidation , the effect of reducing the cost of annealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

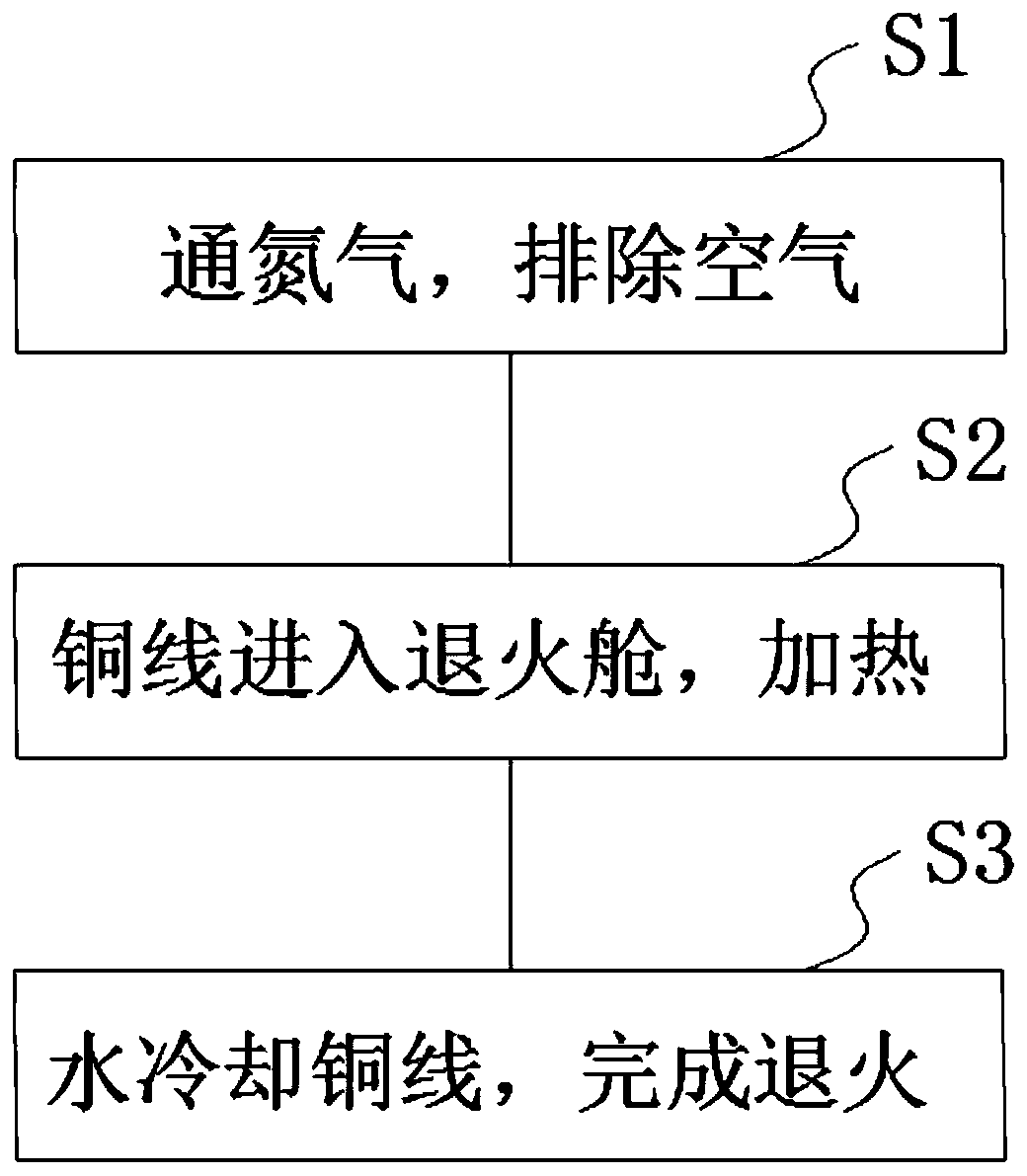

[0025] Such as figure 2 Shown, a kind of copper wire drawing annealing method is characterized in that: comprises the following steps:

[0026] S1. Nitrogen gas, air removal,

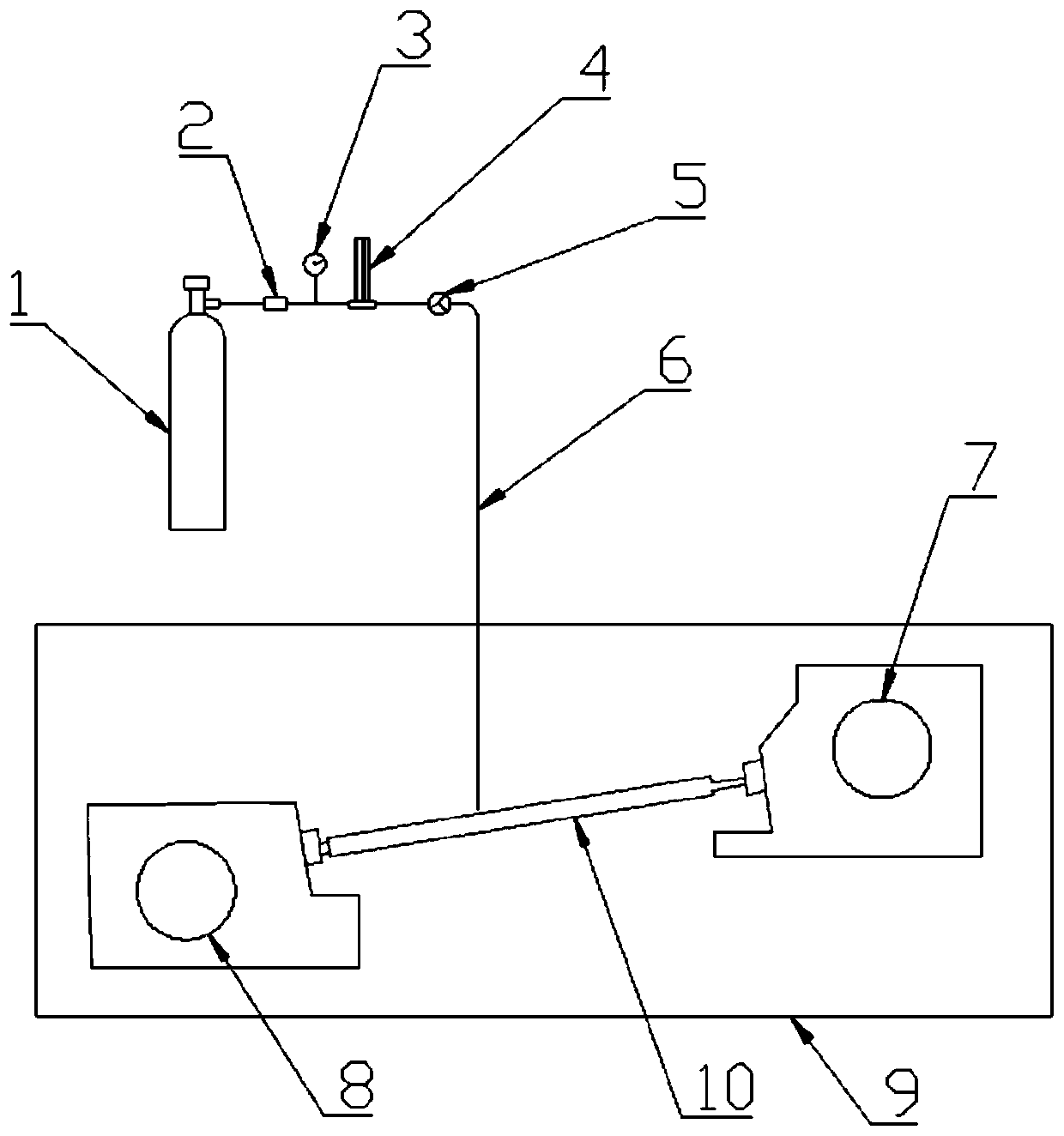

[0027] Such as figure 1 As shown, the nitrogen storage tank 1 is connected with the dryer 2, the flow meter 4, the switch valve 5, and the annealing chamber 9 through the connecting pipe 6 in sequence. 5 control the switch of nitrogen, and finally enter the sealed tube 10 of the annealing cabin 9;

[0028] S2. The copper wire enters the annealing cabin 9 and is heated,

[0029] Fill the sealed tube 10 with nitrogen gas, then pass the copper wire through the sealed tube 10, the copper wire passes through the sealed tube 10 and enters the annealing chamber 9, and is annealed by the first annealing wheel 7 and the second annealing wheel 8; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com