Draft gear of bogie

A technology of traction device and bogie, which is applied in the direction of bogie, transportation and packaging, railway car body parts, etc., and can solve the problems of complex assembly process and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

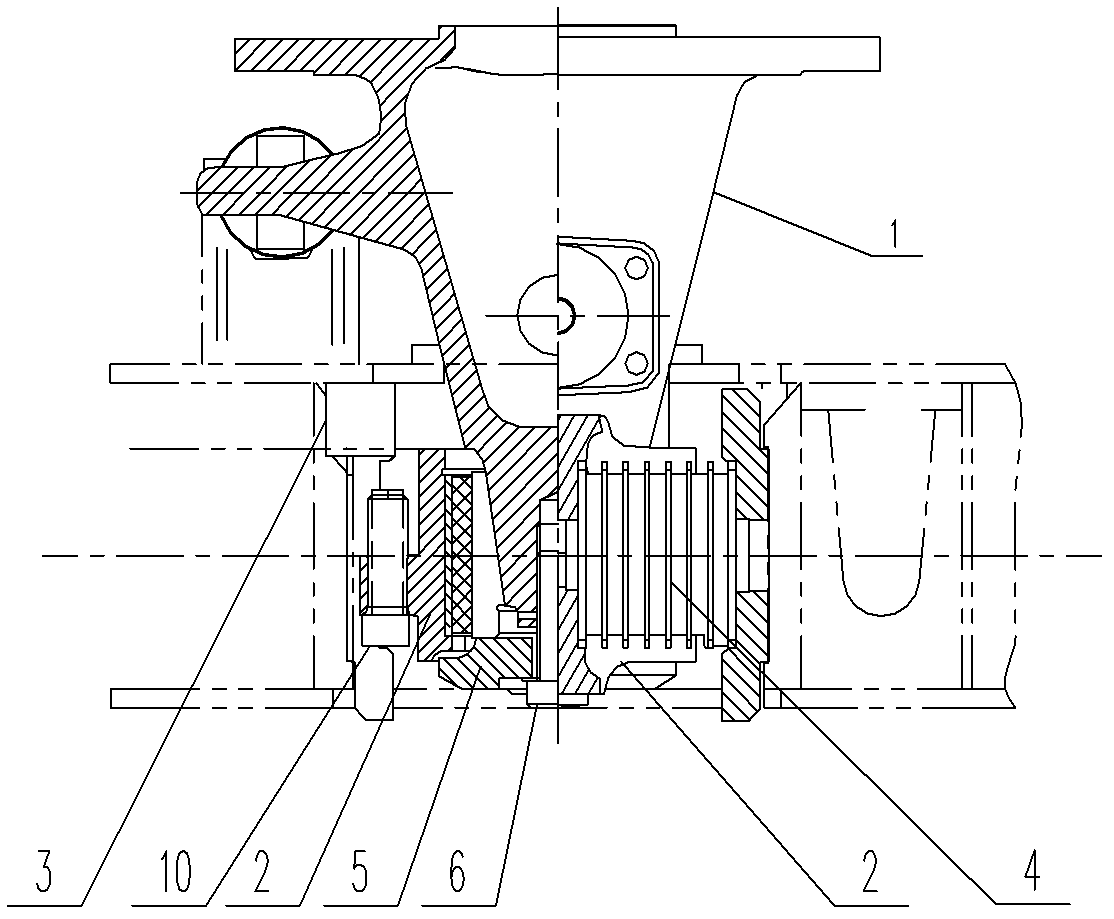

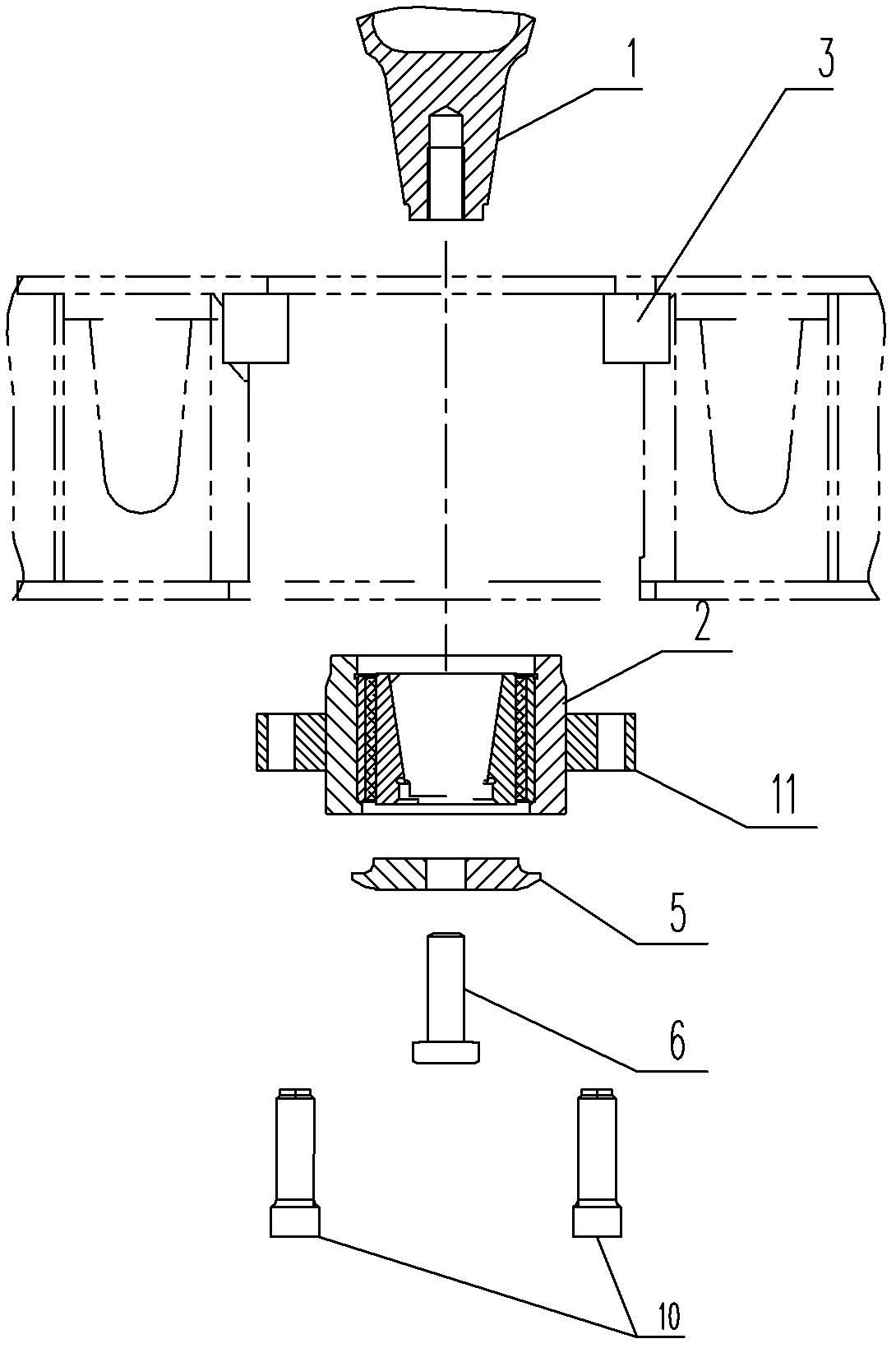

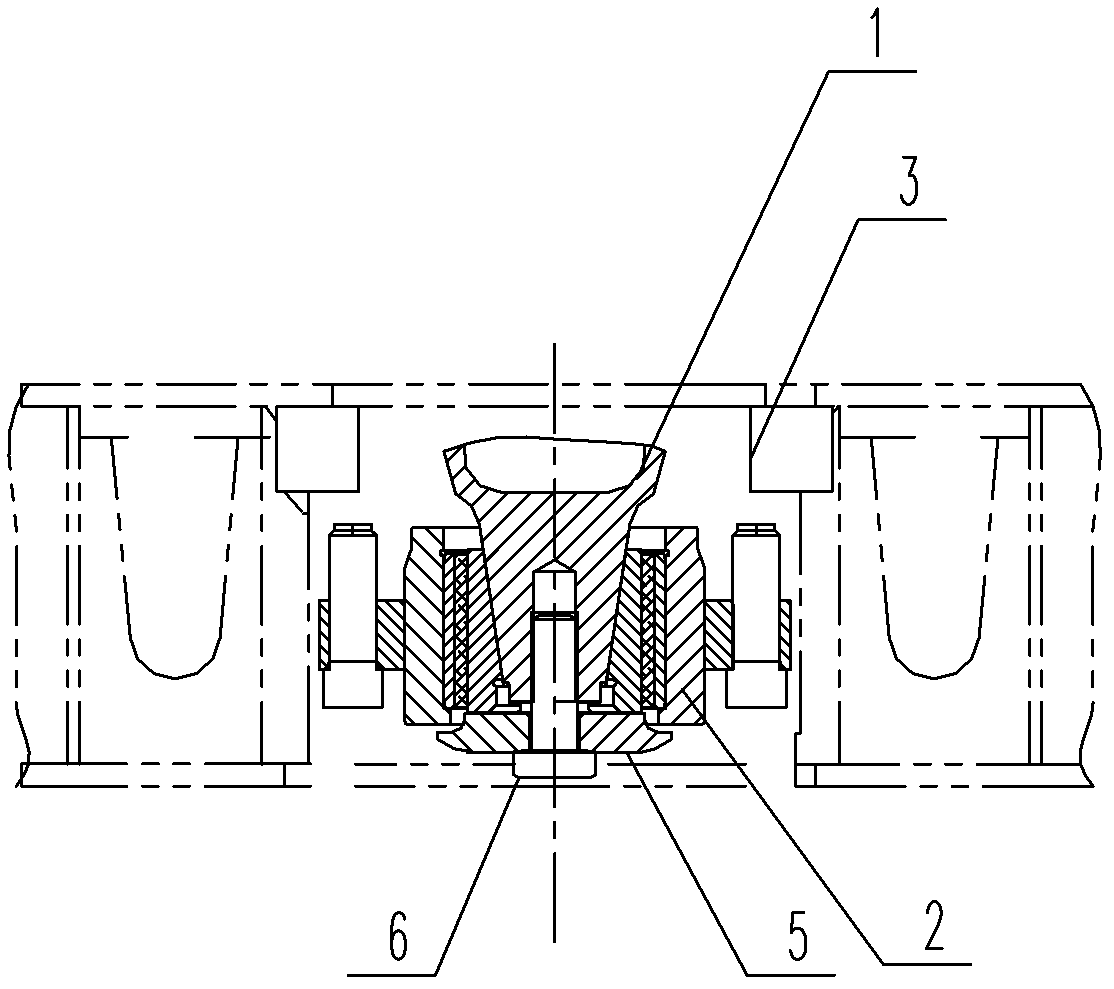

[0024] The bogie traction device of the present embodiment, such as Figure 3-5 As shown, the composition includes: traction center pin 1, traction center seat 2, traction rubber pile 4, anti-overcharge stopper 3, lifting pad 5, which also has a hanging pad 7 fixed under the lifting pad 5, and the outside of the hanging pad 7 The diameter is greater than the distance between the anti-overfill stopper 3, and the maximum width of the traction center seat 2 is smaller than the distance between the anti-overcharge stopper 3. In the middle and lower positions, the lifting pad 7 cooperates with the filling stopper 3 to realize lifting. The hanging pad 7 is fixed to the lifting pad 5 by the lifting pad fastening bolt 9, and the hanging pad fastening bolt 9 is screwed into the lifting pad 7 and the lifting pad 5 from bottom to top, and the lower surface of the hanging pad 7 is tightly connected to the lifting pad. Adjustment pads 8 are arranged between the upper surfaces of the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com