Assembled follow fixture system

A technology of accompanying fixtures and elevators, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of slow workpiece transmission, inconvenient use, and low operating accuracy, and achieve high reciprocating operation accuracy, simple maintenance, and The effect of a high degree of standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

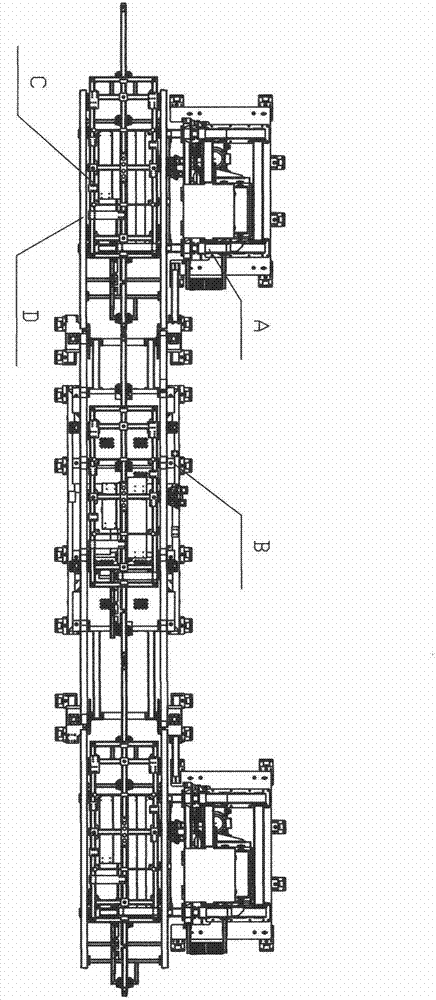

[0015] refer to Figure 1-4 , this specific embodiment adopts the following technical scheme: it includes elevator equipment A and double-layer transmission equipment B, and the two sides of double-layer transmission equipment B are provided with elevator equipment A.

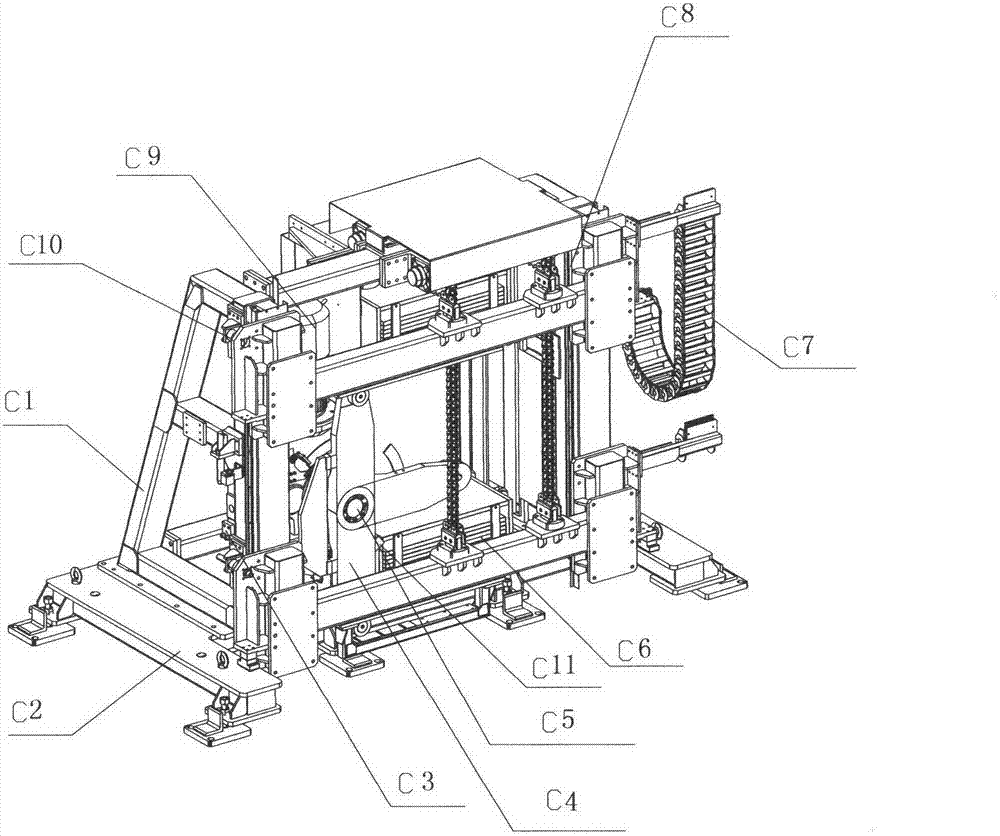

[0016] The elevator equipment A includes a lifting device C and a lifting transmission device D, and the lifting transmission device D is installed above one side of the lifting device C.

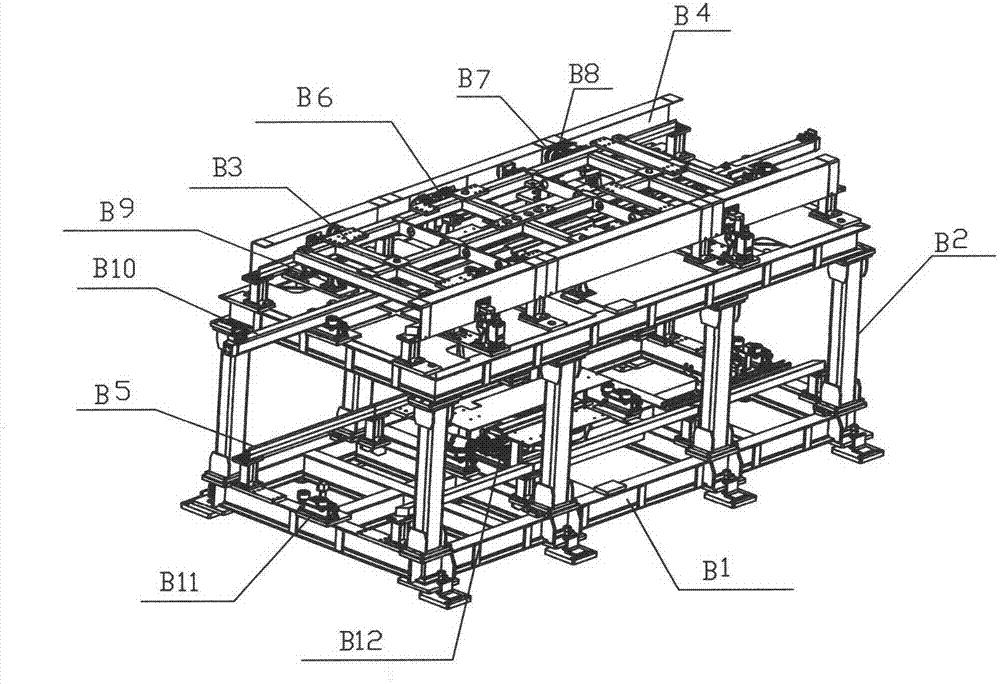

[0017] The double-layer transmission equipment B includes a transmission frame B1, a lifting connection frame B2, a transmission trolley B3, a first guide rail B4, a second guide rail B5, an X-direction positioning block B6, a Y-direction positioning block B7, a roller B8, and a Z-direction positioning block. The positioning block B9, the reciprocating rod B10, the guide wheel B11 and the motor limit transmission device B12, the guide wheel B11 is arranged on the middle cross bar of the transmission frame B1, the motor limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com