Feeding adjustment stud on sewing machine

A technology for adjusting studs and sewing machines, applied in sewing machine components, sewing equipment, cloth feeding mechanisms, etc., can solve the problems of reducing product quality, high noise, affecting the performance of the whole sewing machine, etc., so as to reduce noise, reduce production costs, and improve The effect of the performance of the whole machine and the quality of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

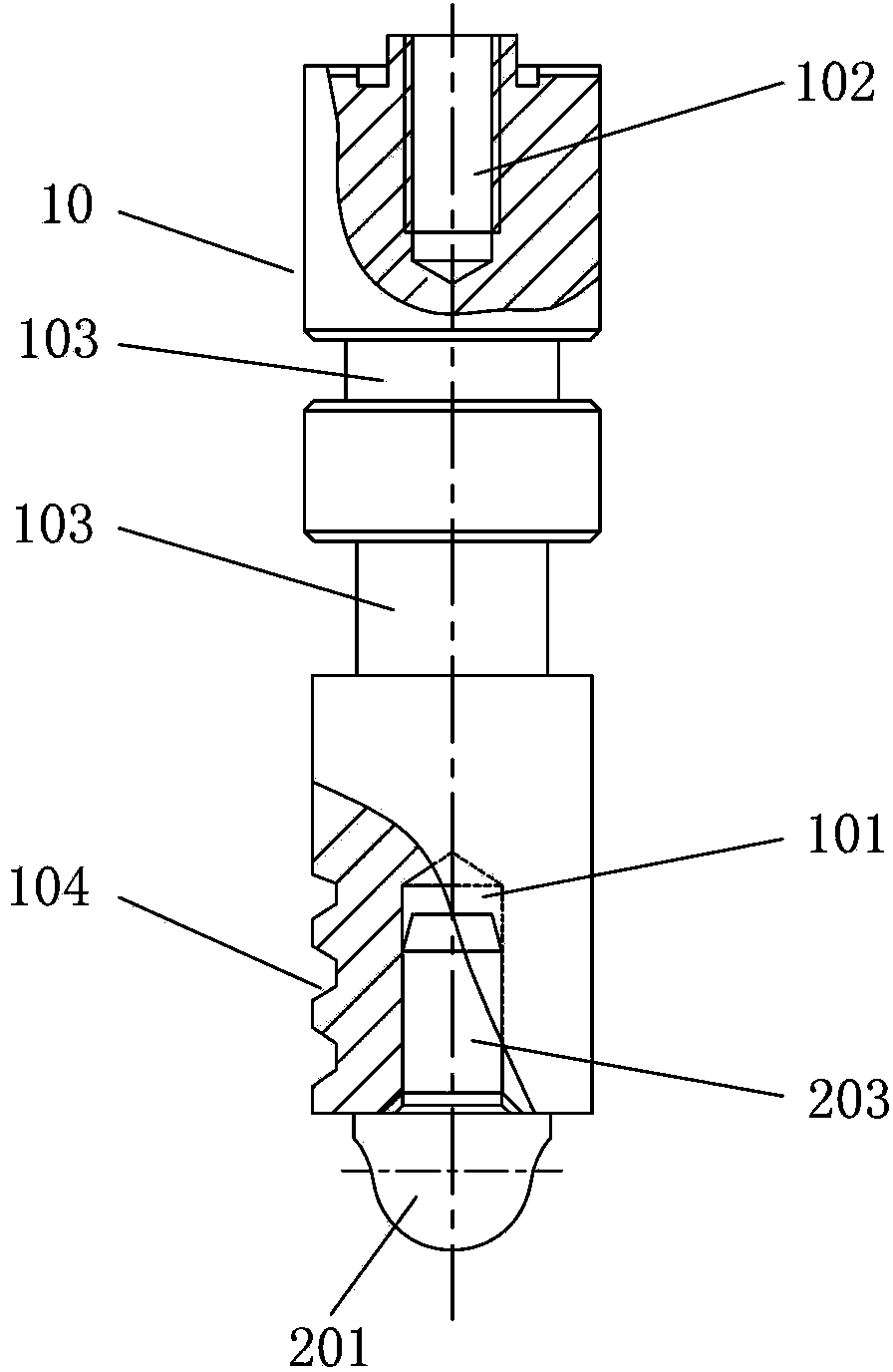

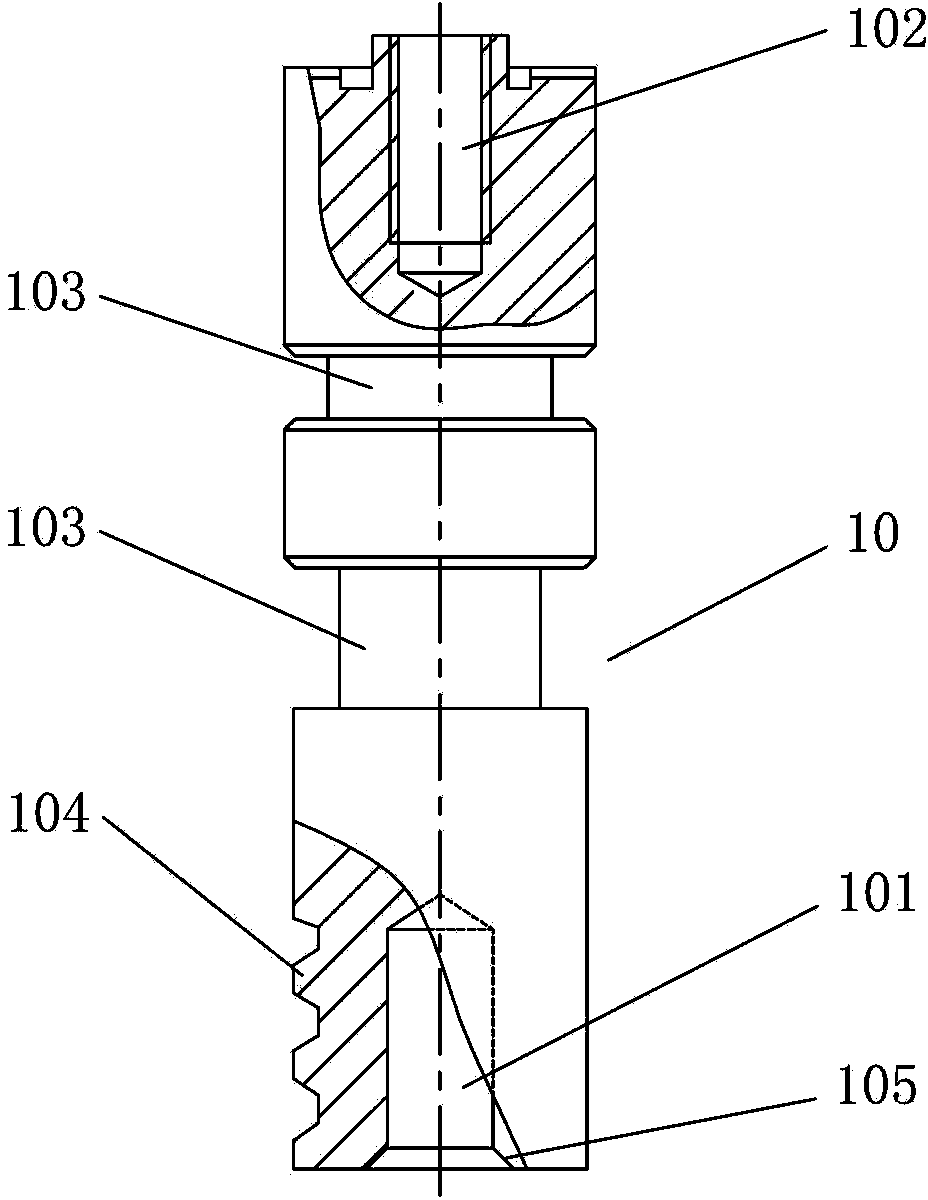

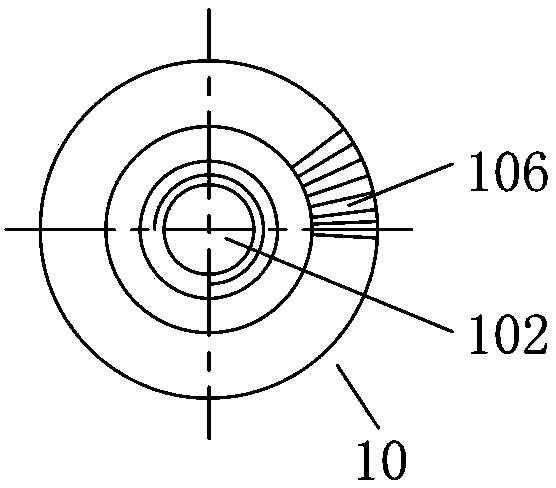

[0020] The present invention will be further described below with specific embodiment, see figure 1 —4:

[0021] The feeding adjustment stud on the sewing machine includes an adjustment stud cylinder 10 and a head 20 connected in contact with the feed regulator. The axes of the cylinder body 10 are collinear.

[0022] The above-mentioned adjusting stud cylinder 10 is: one end of the cylinder is axially provided with a head mounting hole 101 collinear with the axis of the cylinder, and the other end is provided with a threaded hole 102 whose axis is collinear with the cylinder. Two constricted portions 103 are provided at intervals in the middle of the outer cylindrical surface of the cylinder, and external threads 104 are arranged on the outer cylindrical surface of the cylinder near the end where the head mounting hole 101 is provided. The external thread 104 is a trapezoidal thread or a rectangular thread.

[0023] The opening end of the head mounting hole 101 of the adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com