Connecting structure for self-tension pull bar

A technology for connecting structures and tie rods, which is applied in the direction of building components, building structures, walls, etc., can solve the problems of single method of applying pre-tightening force, inability to apply large and medium-sized equipment on site, and cumbersome on-site operation, etc., to achieve beautiful exterior decoration , humanized design, solid and durable overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

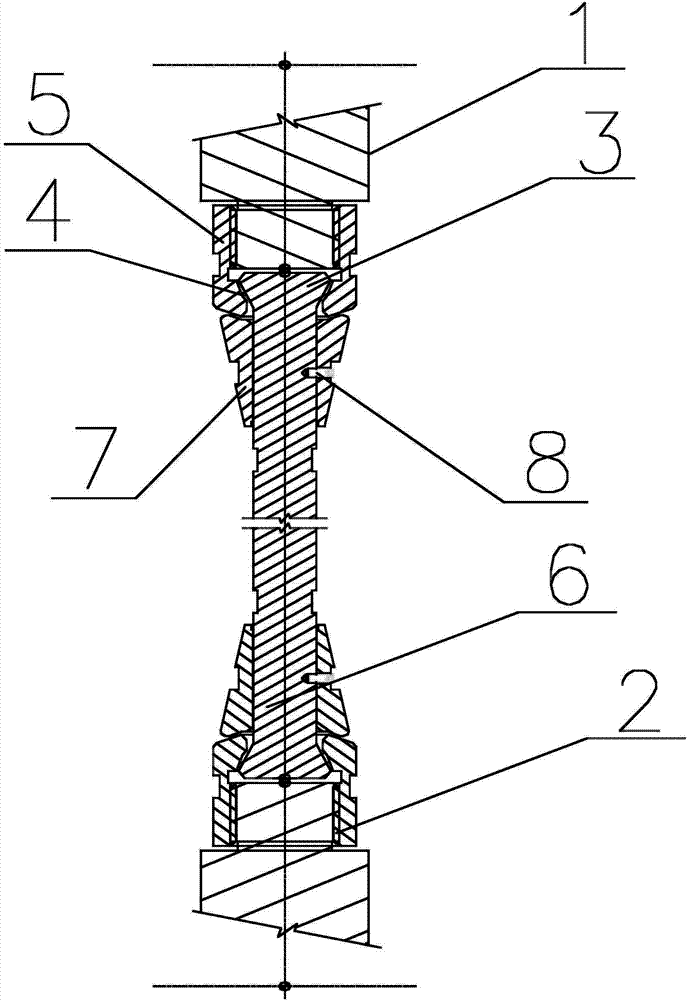

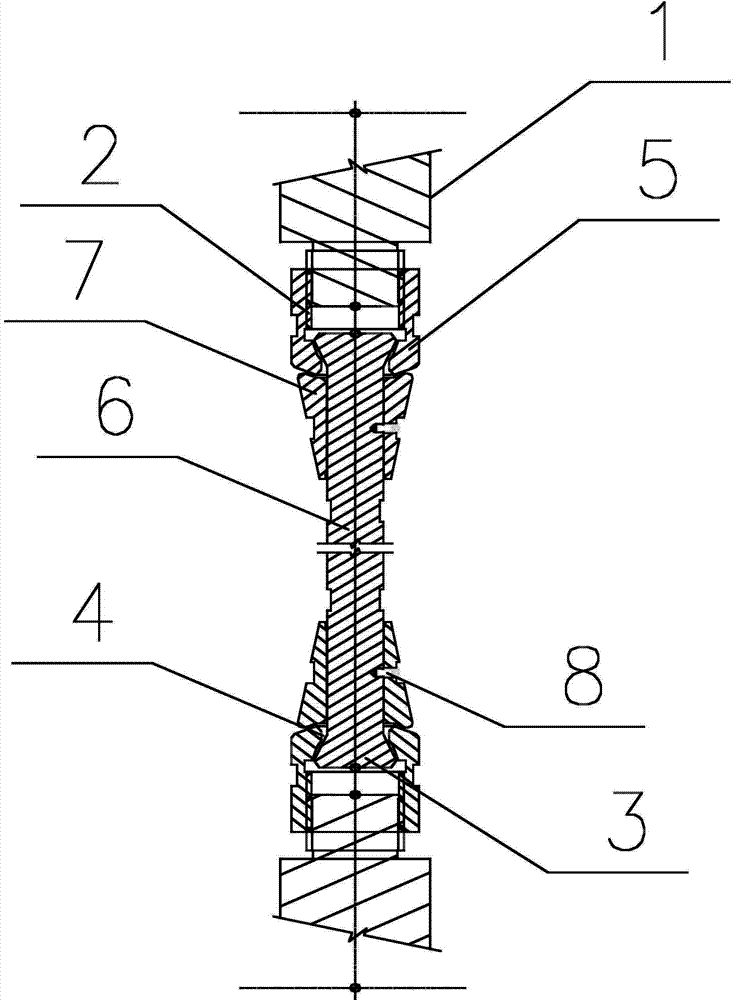

[0017] Such as figure 1 , figure 2 As shown, a self-tensioning tie rod connection structure includes a tie rod 6 with ball ends 3 at both ends, and connecting posts 5 are respectively arranged on the ball ends 3 of the tie rods 6; the outer ends of the connecting posts 5 have internal threads 2. The inner end has a spherical groove 4, and the ball end 3 of the tie rod 6 is matched with the spherical groove 4 of the connecting column 5; the tie rods 6 inside the two connecting columns 5 are respectively provided with dead end pads 7, The dead head block 7 is fixed on the pull rod 6 through a top screw 8, and the top screw 8 plays a position-limiting role. All components of the present invention are made of stainless steel.

[0018] During the connection process, the internal thread 2 of the connecting column 5 of the present invention is connected with the stud 1 with external thread; this structure can resist component deformation caused by temperature expansion and contrac...

Embodiment 2

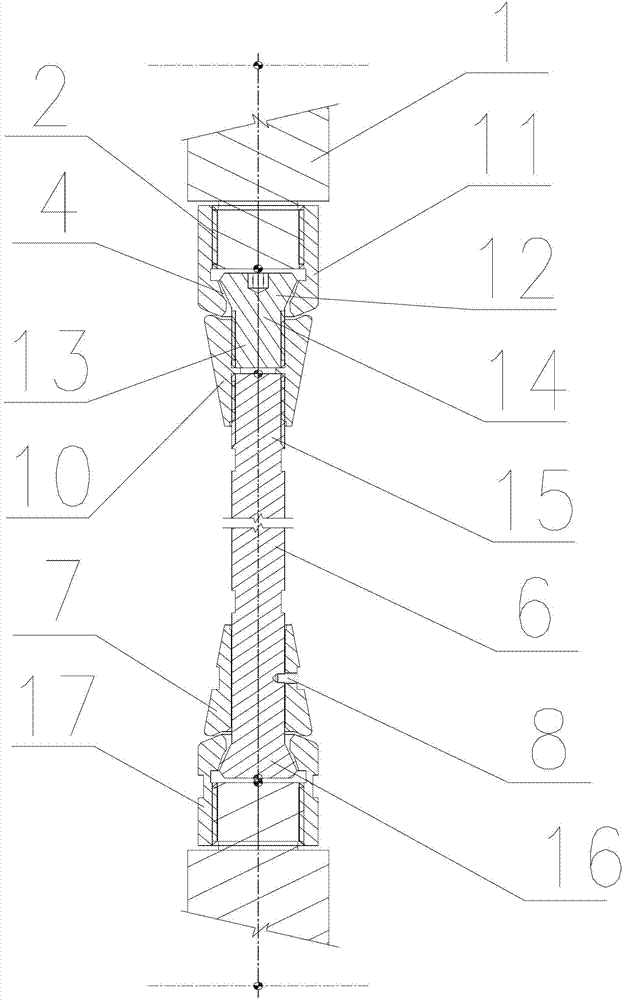

[0021] Such as image 3 , Figure 4 As shown, a self-tensioning tie rod connection structure includes a pull rod 6, a pendulum rod 14, a movable head block 10, a dead end block 7 and a connecting column 5, and one end of the pull rod 6 is a rod end with an external thread, and the other One end is a ball end, and one end of the pendulum rod 14 is a rod end with external threads, and the other end is a ball end, and the pendulum rod 14 plays the role of connecting the first connecting column 11 and the movable head block 10; The ball end 12 of the stick is provided with a first connecting post 11, the outer end of the first connecting post 11 has an internal thread 2, and the inner end has a spherical groove 4, and the ball end 12 of the pendulum stick is connected to the first connecting post 11. The spherical groove 4 matches; the rod end 15 of the pull rod and the rod end 13 of the pendulum rod are all arranged in the internally threaded hole of the movable head pad 10, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com