Header for 630 DEG C steam parameter power station boiler

A technology for power station boilers and steam parameters, which is applied to the components of steam boilers, steam boilers, steam boiler accessories, etc., can solve problems such as poor thermal fatigue resistance, and achieve excellent fatigue resistance, simple structure, and safety requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

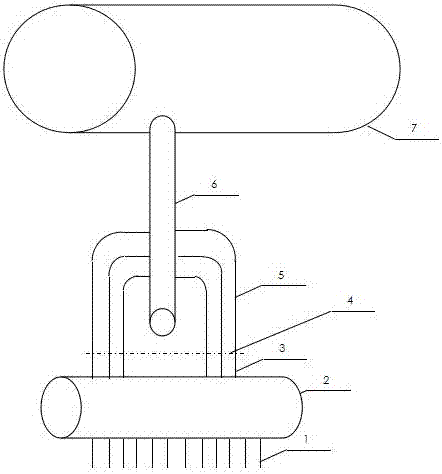

[0021] A header for a 630°C steam parameter power plant boiler, which consists of: a large header 7 and a small header 2, the large header is a high-temperature steam collection header, and the small header is a high-temperature heating surface steam Outlet header, the high-temperature heating surface steam outlet header is connected to the high-temperature heating surface pipe of the high-temperature heating surface steam outlet header through a set of pipe joints A1, and the high-temperature heating surface steam outlet header is connected through a set of The pipe joint B3 is connected to the pipe joint C5, and the pipe joint C is connected to the large header connecting pipe 6, and the large header connecting pipe is connected to the high-temperature heating surface steam outlet header.

Embodiment 2

[0023] According to the header of the 630°C steam parameter power plant boiler described in Example 1, the pipe joint A and the pipe joint B are made of TP316H small-diameter pipes, and the pipe joint C is made of G115 small-diameter pipes.

Embodiment 3

[0025] According to the header of the 630°C steam parameter utility boiler described in embodiment 1 or 2, the outer diameter of the pipe joint B and the pipe joint C is less than 108 mm, and the outer diameter of the large header connecting pipe is larger than 108mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com