Mechanical-electrical integrated electronic lock body

An electronic lock and lock body technology, applied in the field of locks, can solve the problems of troublesome assembly, disassembly and maintenance, not economical and applicable, complex structure, etc., and achieve the effects of convenience, reliability, simple structure, and compact structure connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

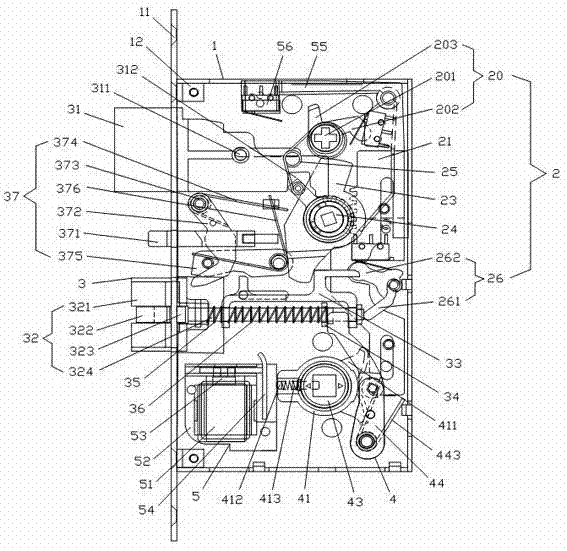

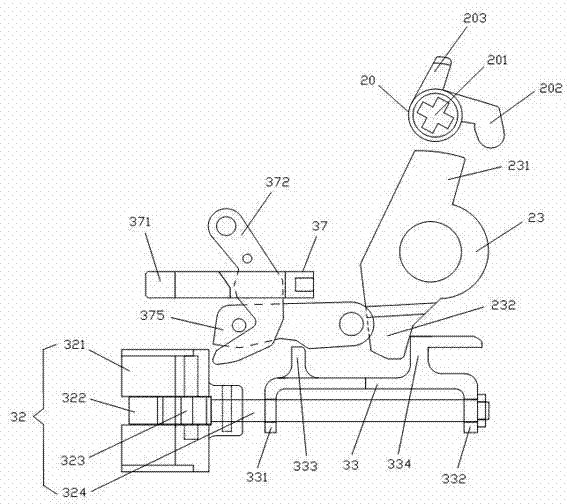

[0121] Such as Figures 1 to 12 As shown, the electromechanical integrated electronic lock body of the present invention includes a lock housing 1 and a mechanical drive mechanism 2 , a locking mechanism 3 , a deadbolt actuator 4 and an electronically controlled drive mechanism 5 disposed in the lock housing 1 .

[0122] The lock housing 1 is used to carry the mechanical driving mechanism 2, the locking mechanism 3, the bolt actuator 4 and the electric control driving mechanism 5. The lock housing 1 is roughly rectangular, and one side is provided with a side trim 11. Both ends are provided with U-shaped connecting plates 12 for assembly.

[0123] The mechanical drive mechanism 2 includes a key toggle 20, a gear plate 21, a gear seat 22, a drive plate 23, a deadbolt toggle 24, a main lock tongue spring 25 and a positive turning throw 26.

[0124] The key toggle 20 is located on one side of the drive plate 23, and includes a key socket 201, a transmission end 202 and a contact...

Embodiment 2

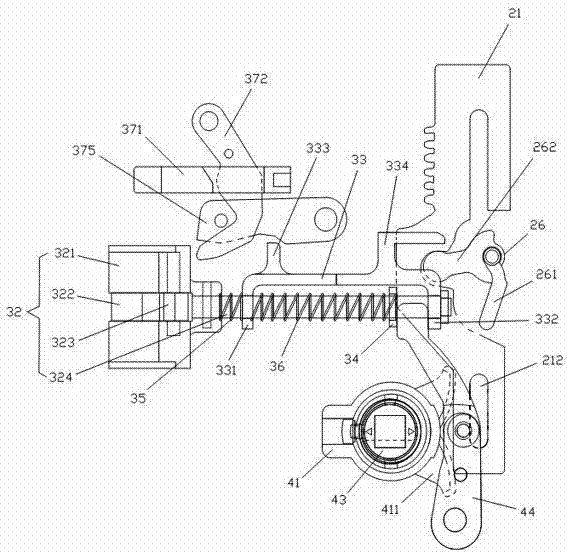

[0150] Such as figure 2 and Figures 13 to 15 As shown, Embodiment 2 of the present invention is the same as Embodiment 1, and also includes a lock case 1 and a mechanical drive mechanism 2 , a locking mechanism 3 , a bolt actuator 4 and an electric drive mechanism 5 disposed in the lock case 1 .

[0151] Compared with Embodiment 1, the electromechanical integrated electronic lock body of Embodiment 2 of the present invention differs in that:

[0152] The mechanical driving mechanism 2 of Embodiment 2 of the present invention includes a key toggle 20, a gear plate 21, a gear seat 22, a drive plate 23, a bolt toggle 24 and a main bolt spring 25, wherein the The gear plate 21 is roughly rectangular, with two guide slots 212 respectively, one side of which is provided with teeth, and the other side is provided with a U-shaped slot 213 .

[0153] The deadbolt actuator 4 of Embodiment 2 of the present invention includes a clutch seat 41, an outer shift fork 42, an inner shift fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com