A test device and test method for strong oxidation of lubricating oil

A test device and test method technology, which is applied in the field of engineering lubricants, can solve the problems that multiple oil samples cannot be tested at the same time, the repeatability is poor, and the actual oxidation time is not represented.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

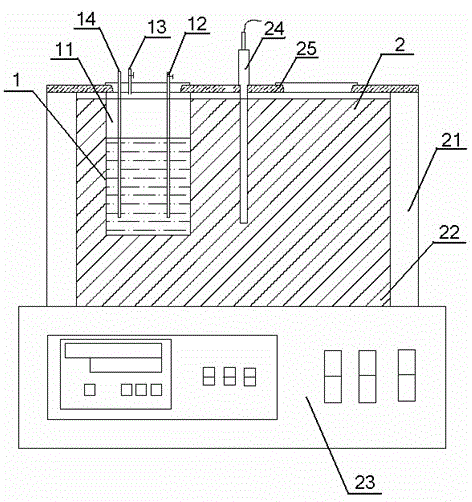

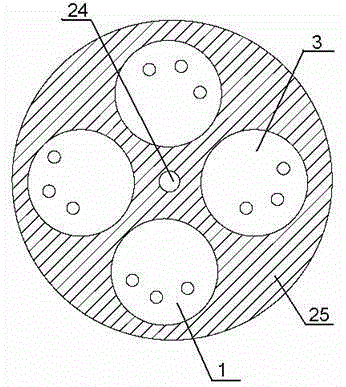

[0035] The present invention will be explained in detail below in conjunction with the accompanying drawings.

[0036] Such as figure 1 A strong oxidation test device for lubricating oil according to an embodiment of the present invention shown in , includes a first oxidation chamber 1 and a heater 2 for heating the first oxidation chamber 1 . The first oxidation chamber 1 is placed in the heater 2 . The first oxidation chamber 1 includes a sealed chamber 11 containing lubricating oil and a sampling tube 12 . The sampling tube 12 is arranged on the sealed cavity 11 , one end of the sampling tube 12 is placed in the sealed cavity 11 , and the other end of the sampling tube 12 is placed outside the sealed cavity 11 .

[0037] The embodiment of the present invention adopts adjustable temperature conditions and a sampling tube 13 that can be sampled and ventilated at any time, and has a simple structure and greater flexibility in operation.

[0038] In the embodiment of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com