Method and device for compressing numerical control machining built-in parts

A pressing device and embedded technology, applied in metal processing machinery parts, positioning devices, metal processing equipment, etc., can solve the problems of tool damage, collision risk, surface level difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

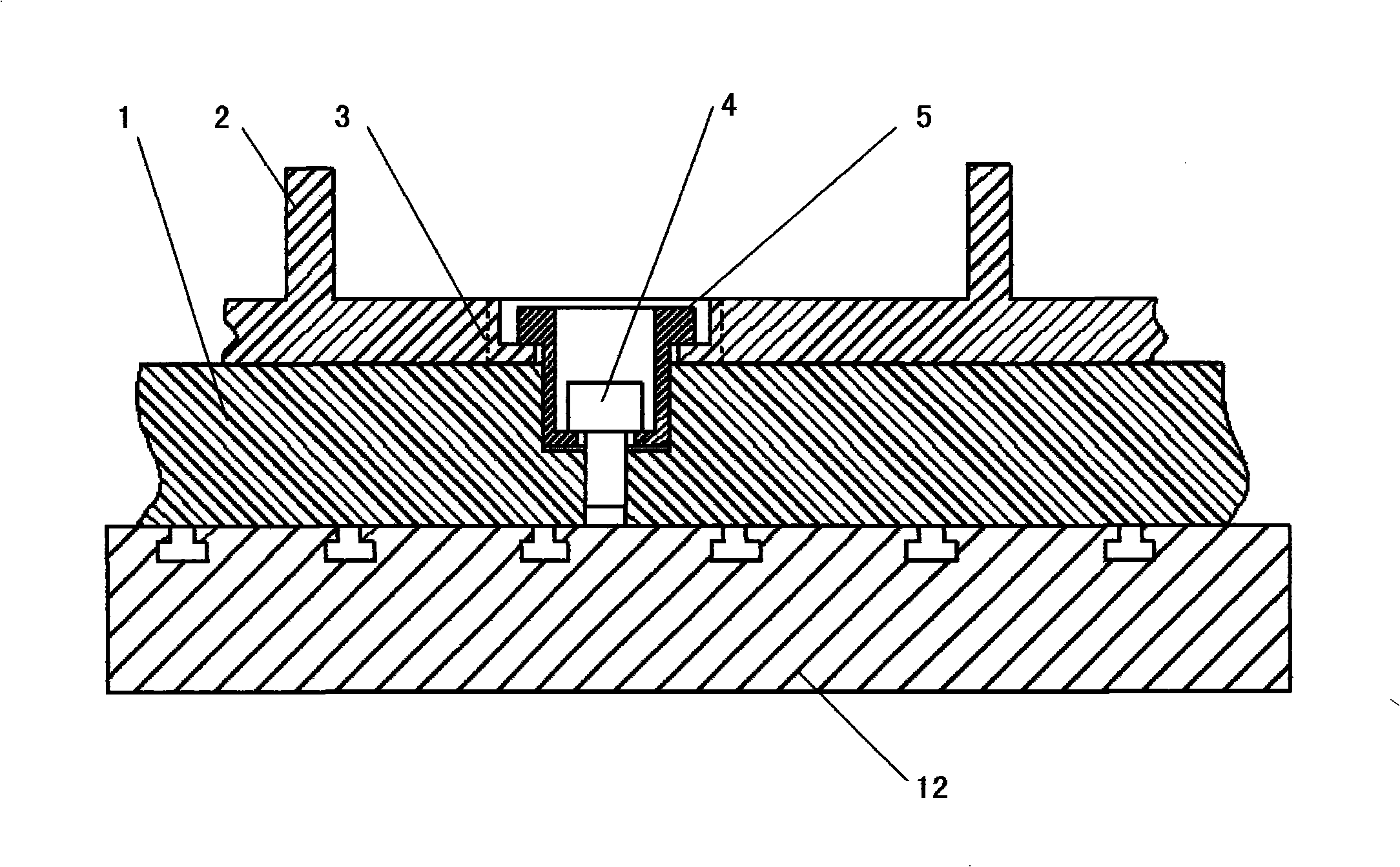

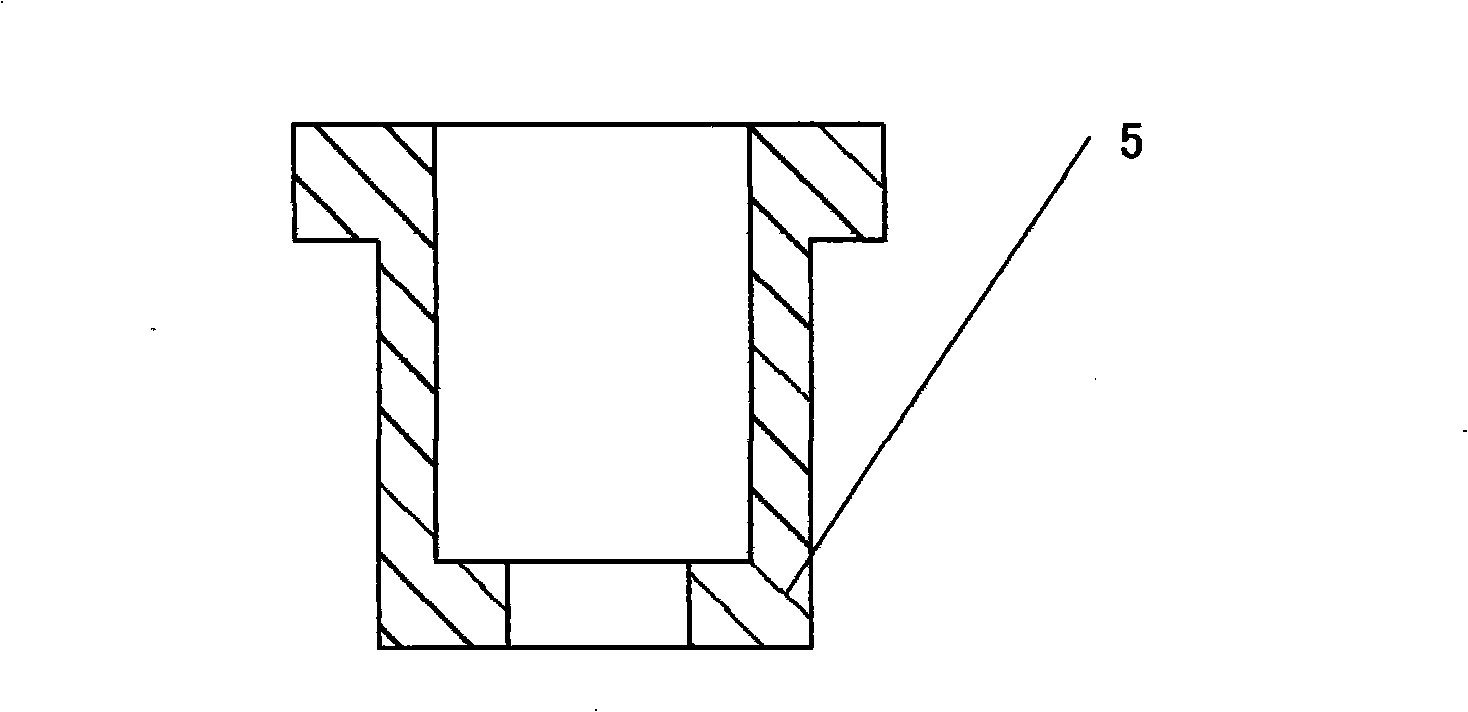

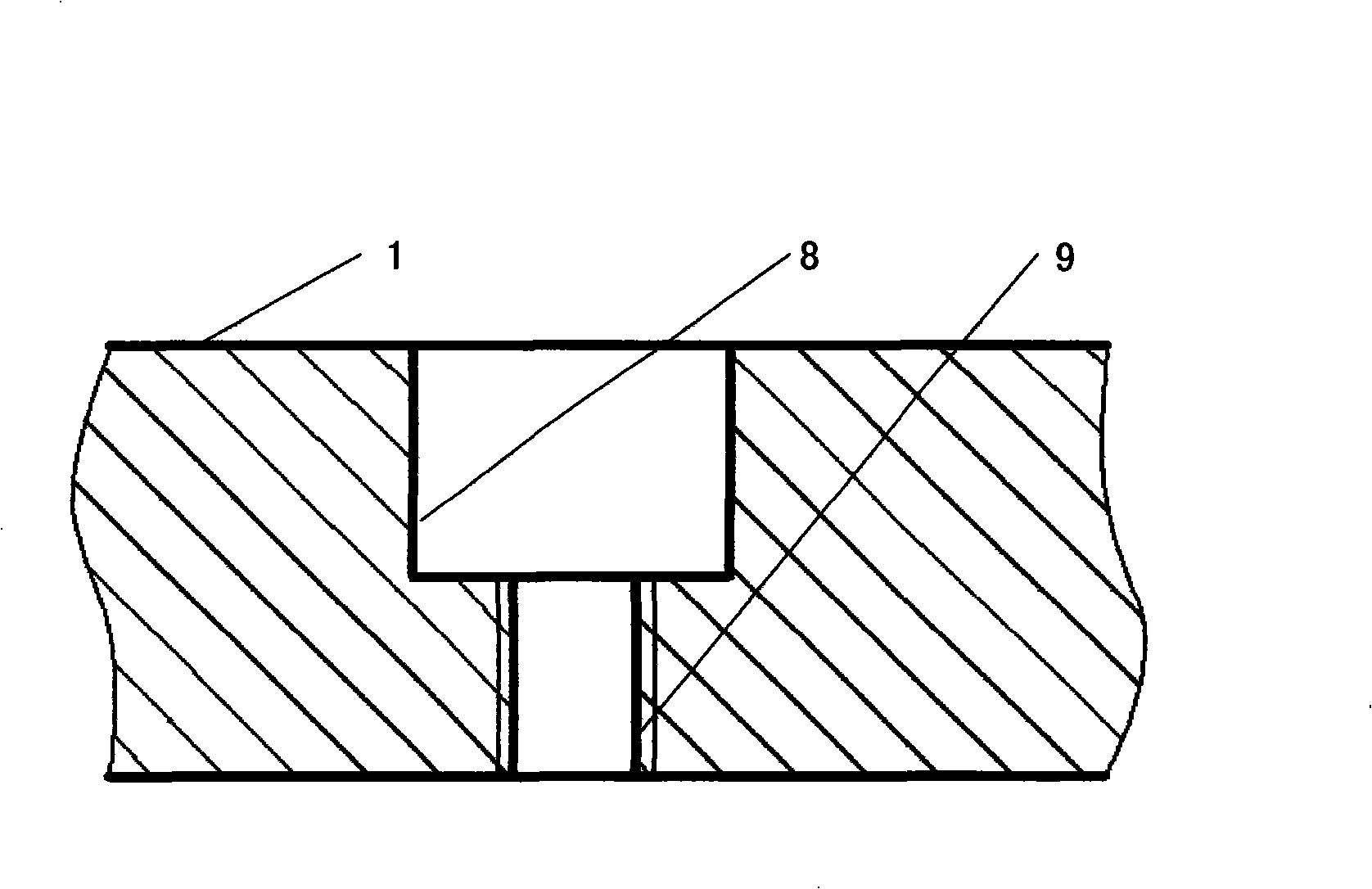

[0021] see figure 1 , the structural gap 3 of the part 2 is set as the clamping and pressing point, and a step hole 6 is provided on the pressing point. The fixture platform 1 is a metal platform larger than the outline of the part, and the fixture platform can be fixed on the workbench 12 of the CNC machine tool On the fixture platform, there is a counterbore 8, the part 2 to be processed is placed on the fixture platform 1, the step hole 6 of the part 2 corresponds to the position of the counterbore 8 on the fixture platform, and then the bushing 5 is pressed against the part and fix the bushing in the counterbore of the fixture platform with fasteners 4.

[0022] The implementation of the embedded compression method is firstly to select the appropriate position and structural gap to set the compression point 11 for the part 2 to be processed. Generally, select the structural holes, gaps and other parts on the part (too small holes cannot be used) , roughly evenly distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com