Intelligent full-automatic integral Zea mays noodle maker

A noodle machine, fully automatic technology, applied in the direction of dough mixer, dough extruder, dough forming machinery or equipment, etc., can solve the problems of discontinuous discharge, discontinuous noodles, easy to break, etc., to achieve good heat dissipation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

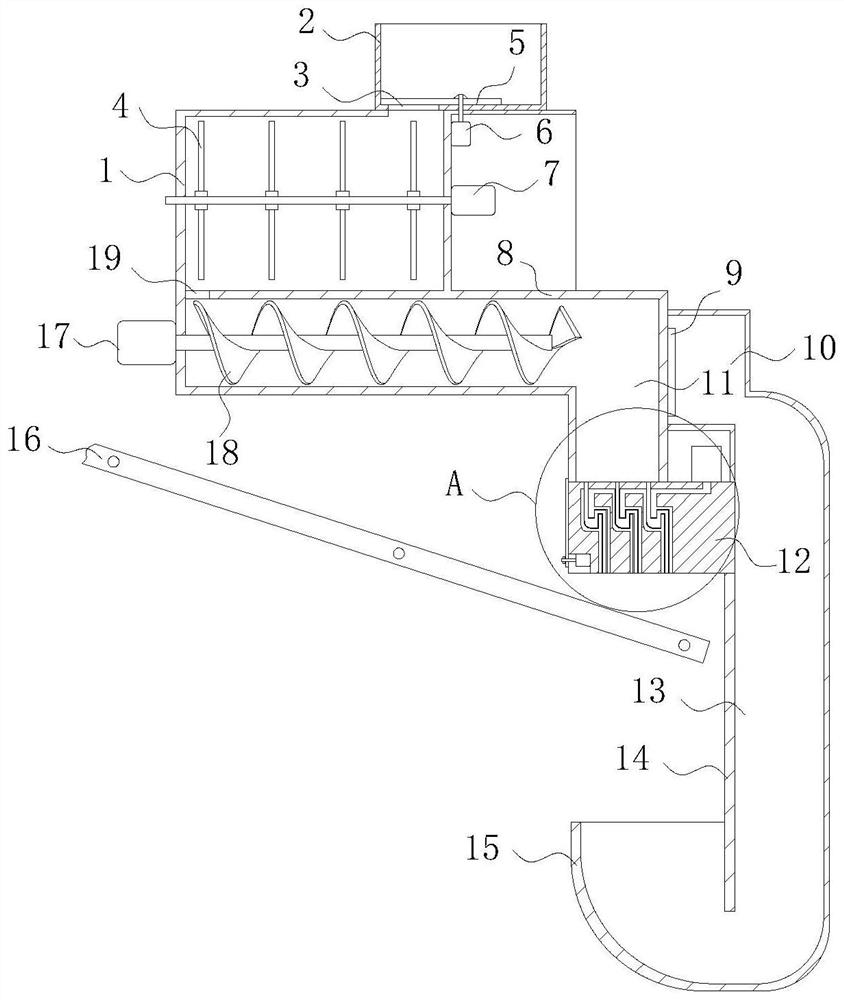

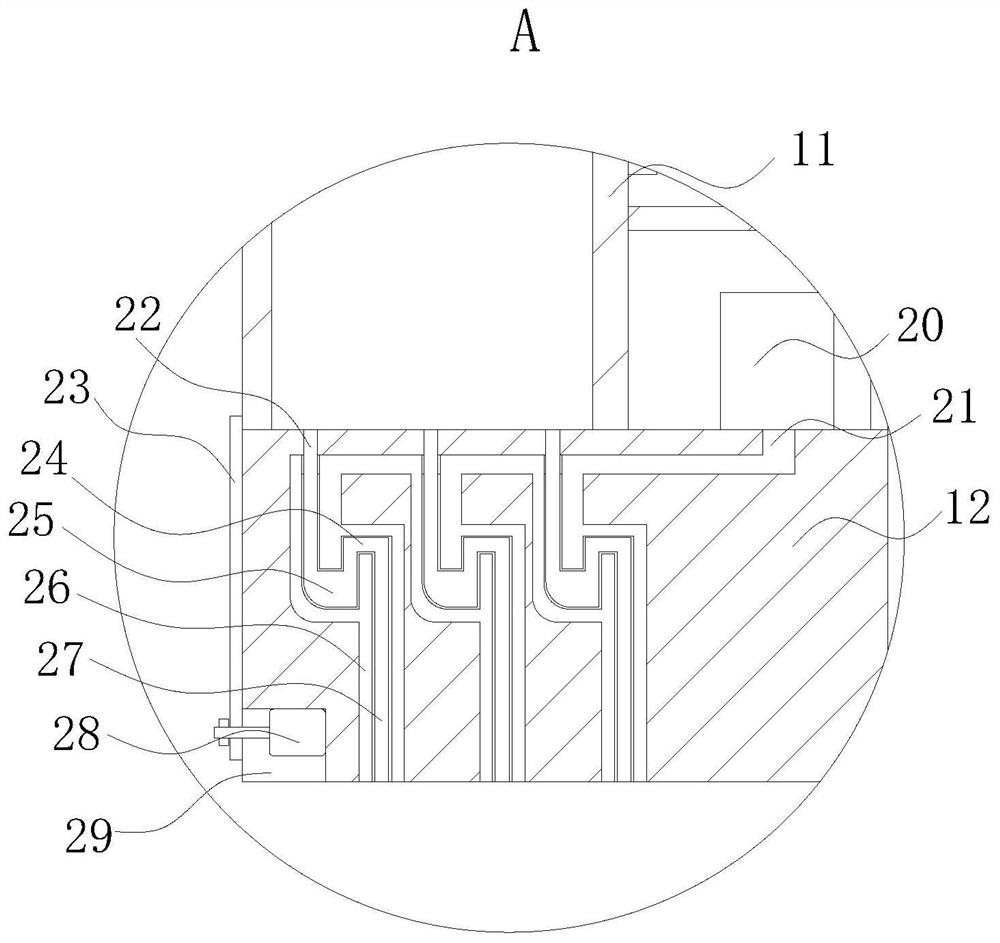

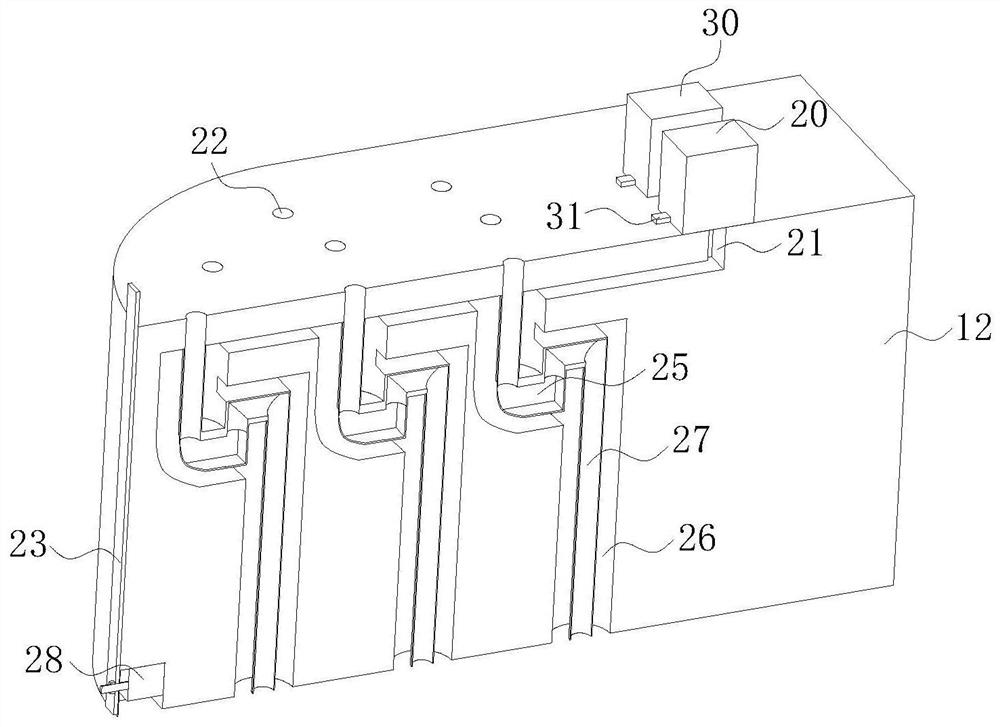

[0030] As an embodiment of the present invention, the lower side of the forming box 12 is provided with a partition 14; one side of the partition 14 is provided with a U-shaped outer plate 15; the partition 14 and the outer plate 15 A circulation channel 13 is formed between them, and the opening of the circulation channel 13 corresponds to the directly below the molding box 12 ; the upper end of the circulation channel 13 leads to the heating box 10 . When working, when the cold air passing through the air inlet unit 20 passes through the second channel 26 to blow off the heat between the noodles, the heat is driven by the wind and enters downward from the opening of the circulation channel 13, and flows into the heating box 10 through the circulation channel 13. The heat transfers heat energy in the heating box 10 to the processing box 11 through the inner wall of the heating box 10, so as to achieve the purpose of heat recycling.

[0031] Concrete workflow of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com