Strip conveying system

A conveying system and strip technology, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of difficult to meet the actual needs of production, the structure is not compact enough, and the floor area is large, so as to achieve mass production. , to achieve the effect of automatic control and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

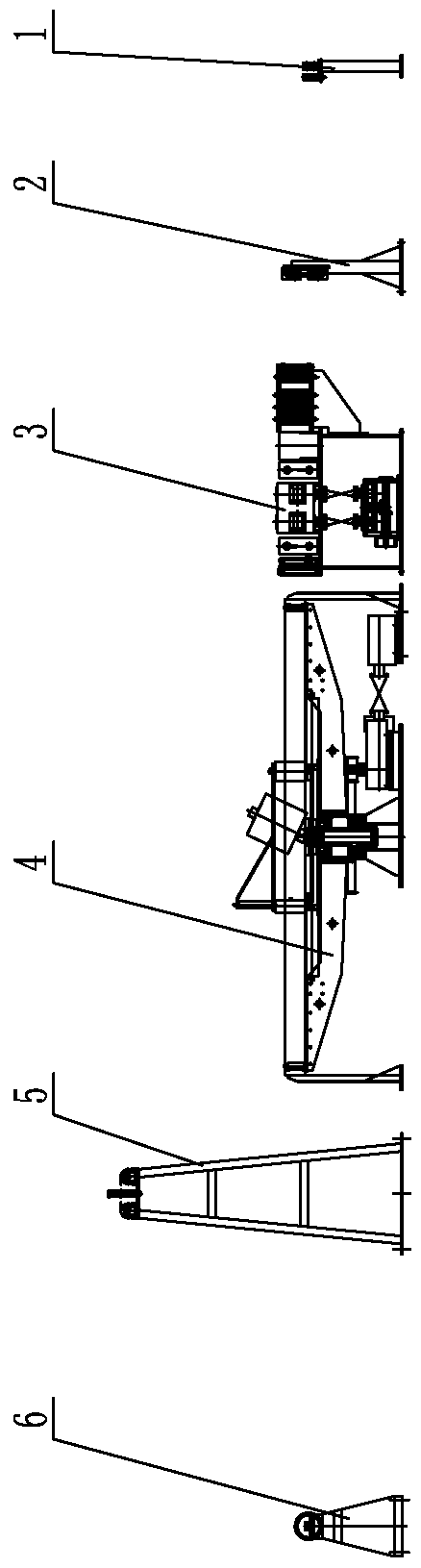

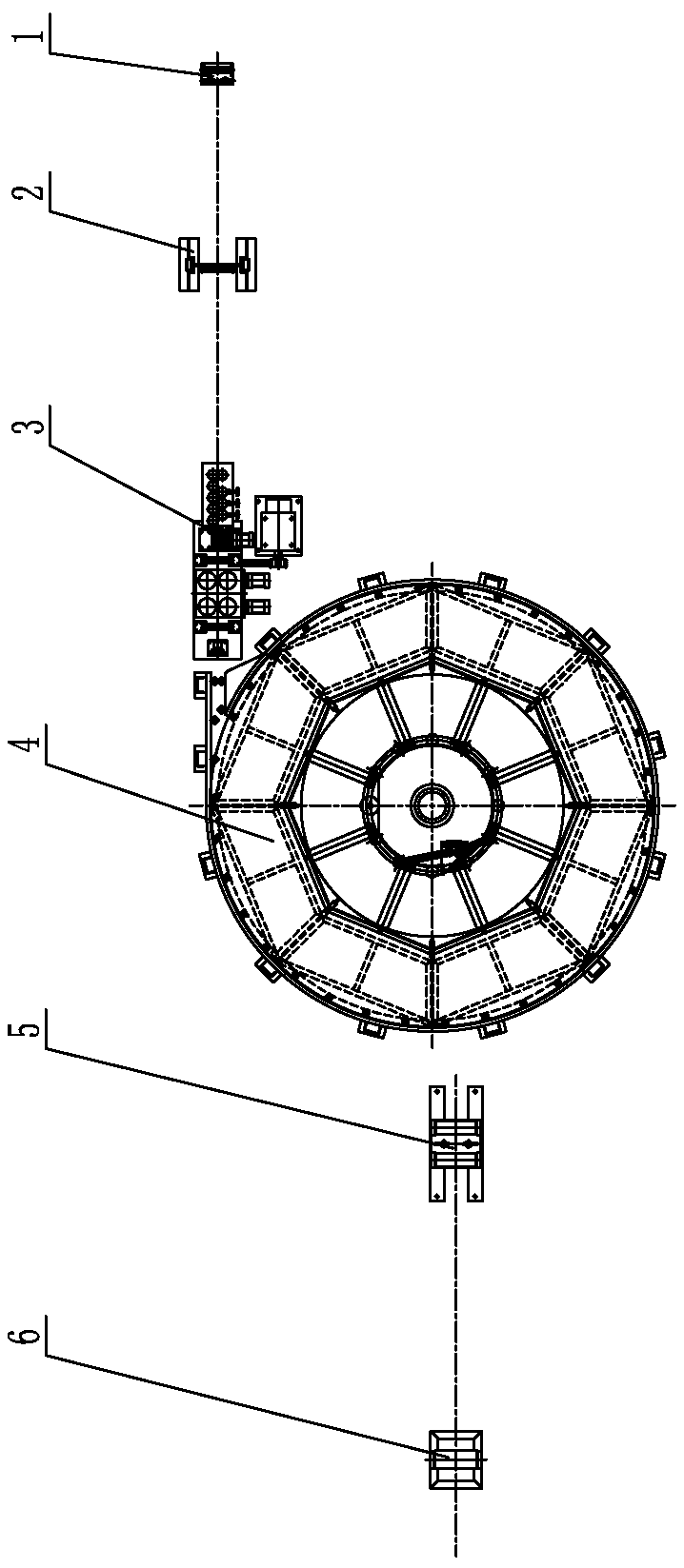

[0032] Such as Figure 1-15 As shown, it is a belt conveying system, which includes a feed guide mechanism, a pinch feeding device 3, a turntable storage device 4 and a discharge guide mechanism arranged in sequence from front to back. The turntable storage device 4 is provided with a feed End and discharge end, the feeding end of the turntable storage device 4 is set correspondingly to the pinch feeding device 3, and the discharge end of the turntable storage device 4 is set correspondingly to the discharge guide mechanism.

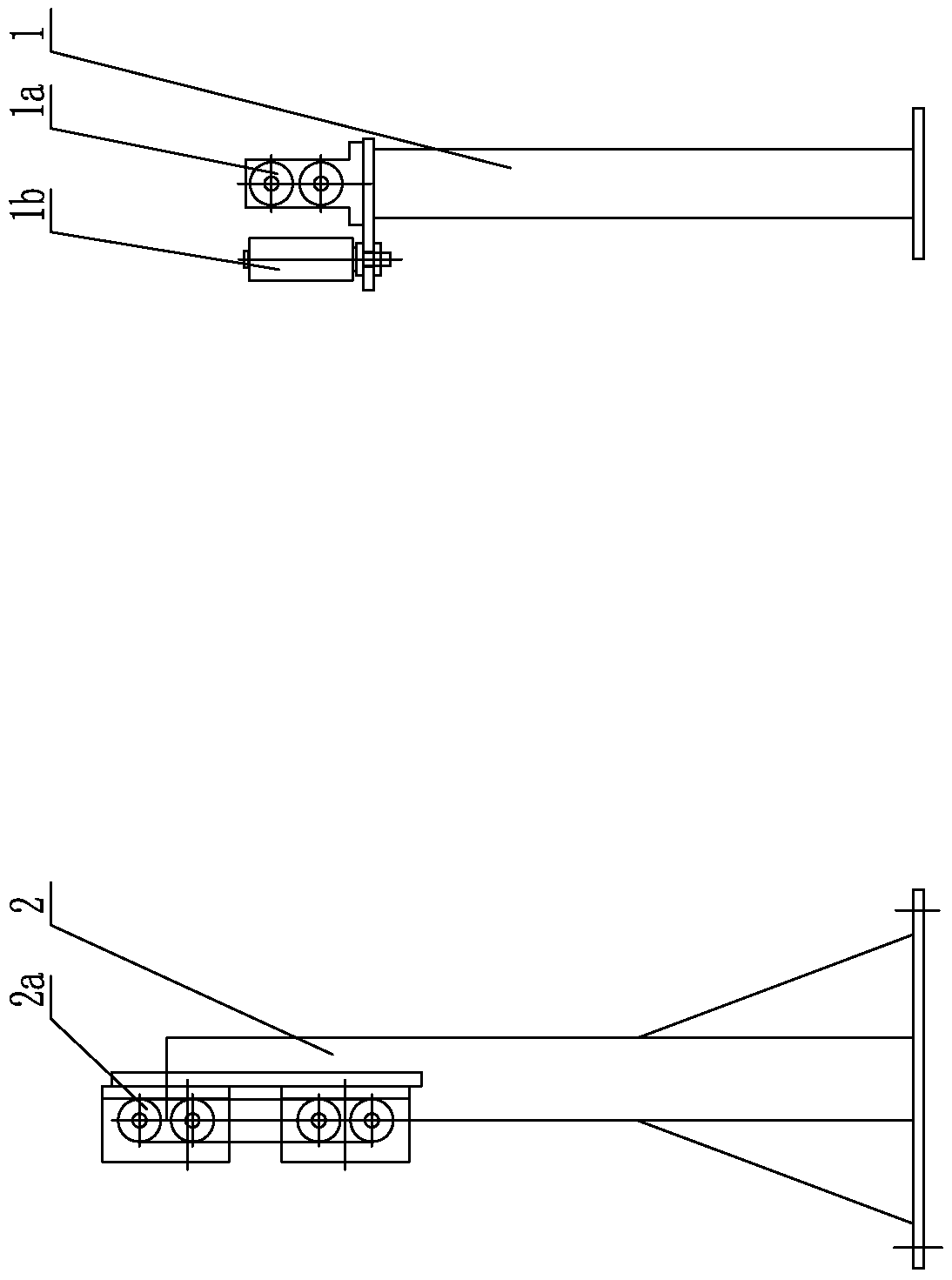

[0033] The feed guide mechanism includes a flat bracket 1 and a direction-changing bracket 2 distributed one after the other. A pair of feeding flat rollers 1a and a pair of feeding vertical rollers 1b are respectively arranged on the flat bracket 1. The feeding flat rollers 1a is arranged correspondingly to the feeding vertical roller 1b, and at least two pairs of direction-changing flat rollers 2a are provided on the direction-changing bracket 2, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com