Mine multiple-system linkage control system based on imaging and control method thereof

A linkage control system and linkage control technology, applied in the direction of electrical program control, comprehensive factory control, etc., can solve the problems of inability to consider system integration, ignoring system connections and interlocking relationships, and equal effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] 1. System construction

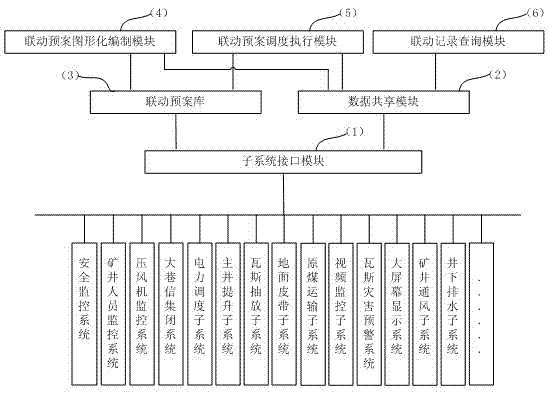

[0045] The system installs data acquisition server, database server, WEB server, management workstation, linkage host and other hardware equipment in the computer room of the mine dispatching center. The subsystem interface module (1), data sharing module (2) and linkage plan are respectively installed in these equipment Library (3), linkage pre-plan graphical compilation module (4), linkage pre-plan scheduling execution module (5) and linkage record query module (6).

[0046] The organization chart of the system is as follows figure 1 shown.

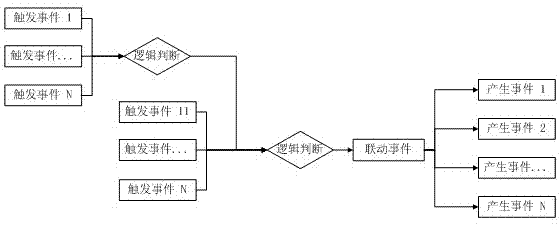

[0047] The subsystem interface module (1) is connected to each subsystem through industrial Ethernet, and is responsible for collecting the data of each subsystem, and then storing it in the data sharing module (2). The graphic compilation module of the linkage plan (4) obtains the collected data points of each subsystem through the shared data module (2), configures and generates the trigger event librar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com