Bell jar type disk-type composite insulator

A composite insulator and disc type technology, which is applied in the direction of suspension/strain insulators, etc., to achieve the effects of reducing operating costs, reducing power frequency arc building rates, and improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

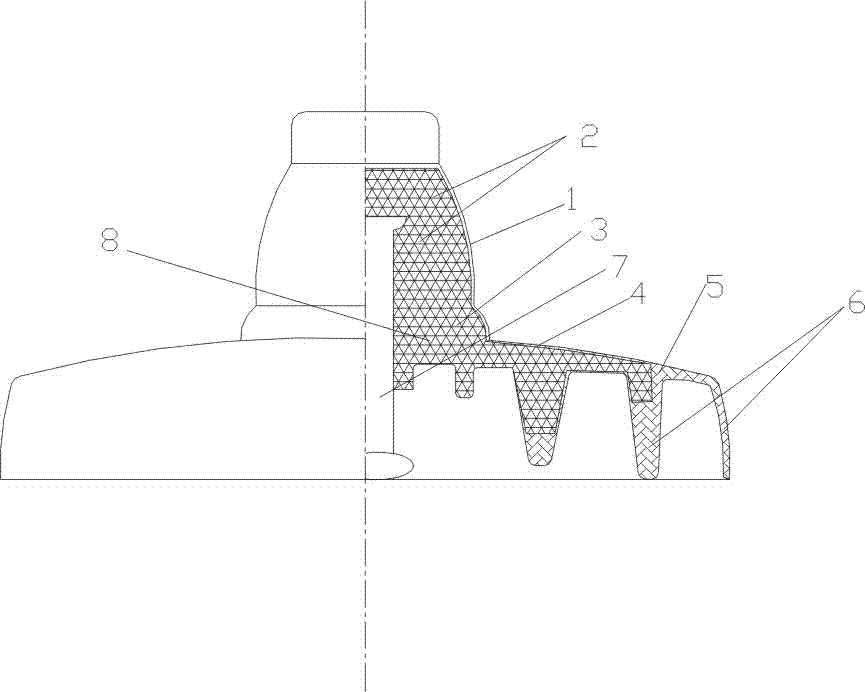

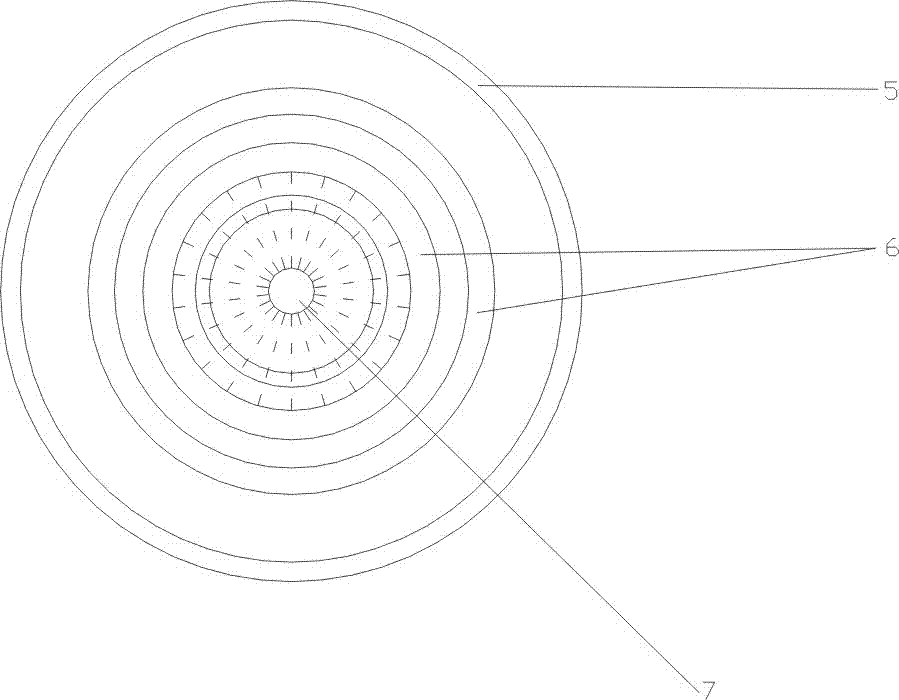

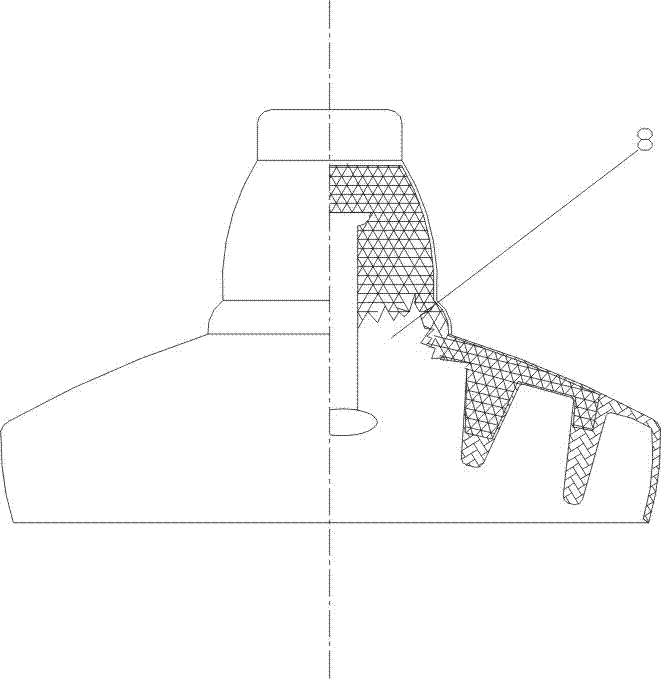

[0012] Bell-type disc-type composite insulator, composed of metal base 1, adhesive 2 tempered glass core 3, coupling agent 4, silicone rubber composite layer and silicone rubber extension shed 5, compounded on the tempered glass inner shed and downward The extended silicone rubber umbrella skirt 6, the metal tie rod 7 and the non-composite silicone rubber area 8 around the metal tie rod 7 are formed. The adhesive 2 in the fitting seat cavity is the insulating filler, and the tempered glass umbrella skirt 3, the fitting holder 1, the metal fitting seat The pull rod 8 is combined into one body, and the upper and lower surfaces of the tempered glass umbrella skirt 3 are compounded with silicone rubber, and form a silicone rubber umbrella skirt extending outward and downward. The contact surface between the upper and lower surfaces of the toughened glass and the silicone rubber layer is through The agent 4 produces molecular effects under high temperature and high pressure, and the...

Embodiment 2

[0014] The bell-type disc-type composite insulator is characterized in that it is composed of a metal base 1, an adhesive 2, a steel ceramic umbrella group 3, a coupling agent 4, a silicone rubber composite layer and a silicone rubber extension shed 5, and is compounded on the inner shed The silicone rubber umbrella skirt 6 extending downward, the metal tie rod 7 and the non-composite silicone rubber area 8 around the metal tie rod 7 are formed. The adhesive 2 in the fitting seat cavity is the insulating filler. The ceramic umbrella skirt, the fitting holder, the metal fittings The pull rods are combined into one body, the upper and lower surfaces of the ceramic shed are compounded with silicone rubber, and the silicone rubber shed is extended outward and downward. Under the molecular effect, the media will penetrate each other, the silicone rubber and the ceramic chain will be integrated, and the 30-50% area under the glass or ceramic core, that is, around the metal tie rod, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com