Multiple-roll dust filter

A dust filter and multi-drum technology, applied in the fields of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of short service life, easy wear of the lead screw, difficult maintenance, etc., and achieve better lubrication effect. Save the cost of use and ensure the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

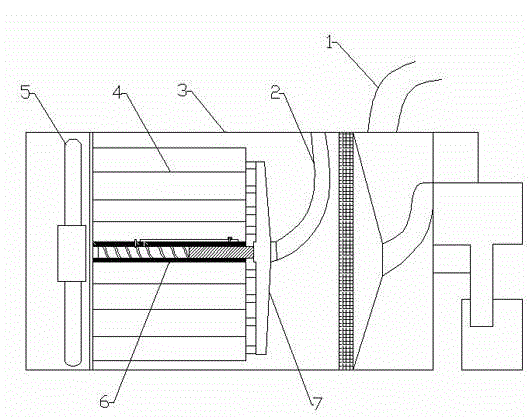

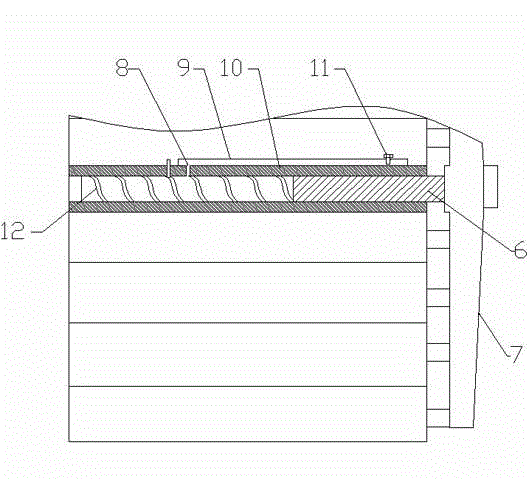

[0016] Specific implementation methods: such as figure 1 , 2 As shown, a multi-drum dust filter includes a device casing 3. One end of the casing 3 is provided with a fan chamber 5, and the other end is a primary dust removal device. The top of the primary dust removal device is provided with an air inlet channel 1, and the middle part is a secondary dust removal device. device, the secondary dust removal device includes a drum type filter cartridge 4, a rotating main shaft 6 is arranged in the middle of the filter cartridge 4, and the main shaft 6 drives several dust suction pipes to rotate in the filter cartridge 4, and a plurality of dust suction pipes are divided by the dust suction pipes. The connector is connected to the main suction pipe 2. The main shaft 6 is a reciprocating lead screw with a thread 12 at one end. The fixed shaft sleeve 10 of the main shaft 6 is provided with an oil storage box 9; the oil storage box 9 is installed above the fixed shaft sleeve 10, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com