Reaction kettle with efficient stirring paddles

A technology of stirring paddle and reaction kettle, which is applied in chemical/physical/physical-chemical stationary reactors, etc., can solve the problems such as prolonging the production time of reactants, failing to achieve rapid cooling, and increasing the production of finished products, thereby reducing weight, Reduced power requirements, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

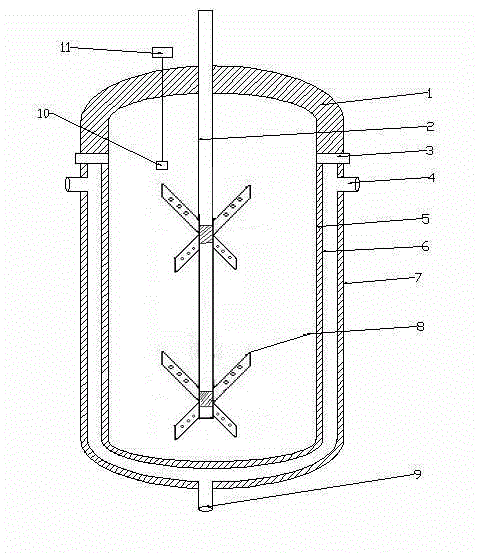

[0015] In order to further understand the reactor with high-efficiency stirring paddles, combined with the attached figure 1 described as follows.

[0016] A reaction kettle with a high-efficiency stirring paddle, which mainly includes: an upper kettle body 1, a lower kettle body and a stirring paddle, and is characterized in that it also includes: a temperature control device and a water circulation device, and the upper kettle body 1 and the lower kettle body are fixed by The device 3 is fixed together, and the stirring shaft paddle passes through the upper kettle body and is placed inside the lower kettle body. The stirring paddle includes: a stirring shaft 2 and a blade group 8, and the blade group 8 is composed of two blades intersecting each other. The included angle of each blade is 30~60 degree, and described blade body is provided with through hole 12, and the diameter of through hole 12 is 10~20mm, and the distance between through hole 12 is the same, between blade g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com