Oiling device for gear case and gear shaft

A technology of oiling device and gear shaft, which is applied to the device and coating of the surface coating liquid, which can solve the problems of unquantifiable oil injection and uneven oil injection by manual operation, so as to save working time, good lubrication effect, and save energy. The effect of working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

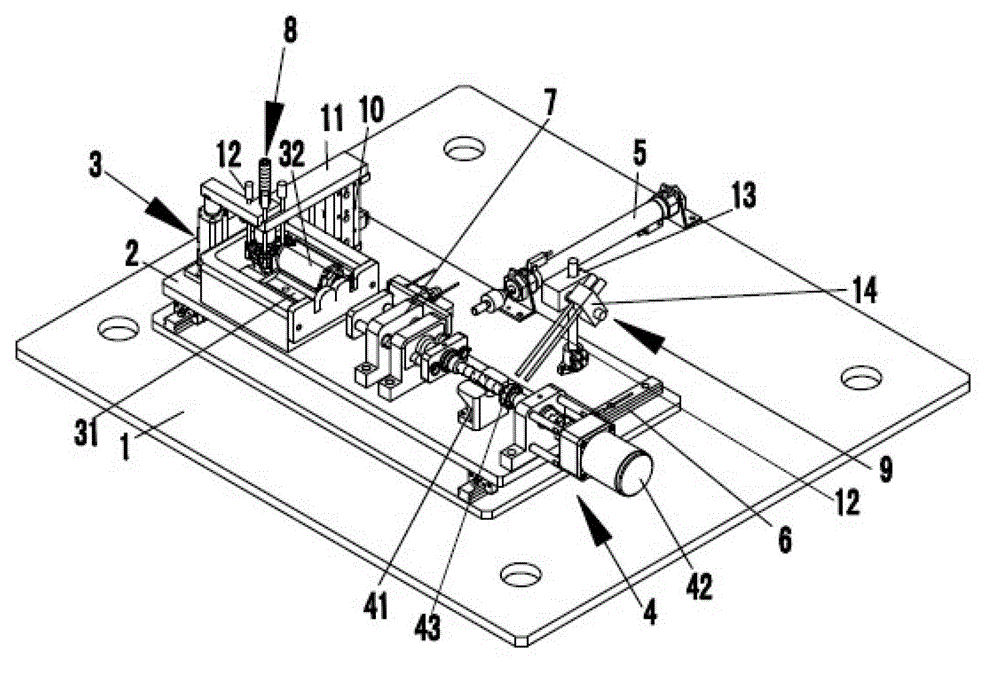

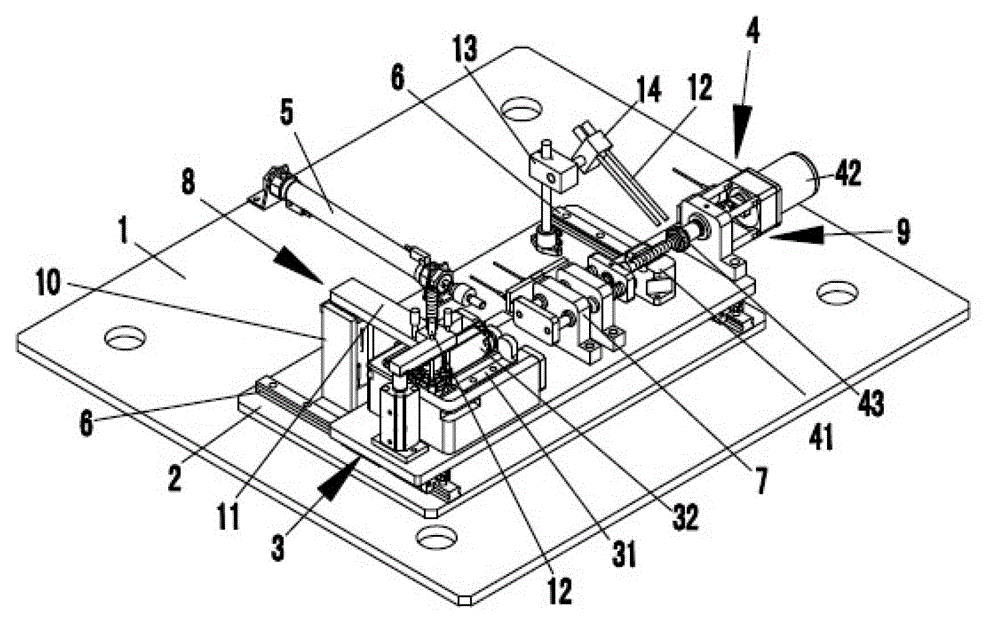

[0025] Such as Figure 1~2 Shown, a gear box, a gear shaft oiling device, including a work surface 1, movable floor 2, gear box oiling station 3, gear shaft oiling station 4, push-pull cylinder 5 guide rail 6 and oiling mechanism; the guide rail 6 set On the work surface 1; the movable bottom plate 2 is slidably arranged on the guide rail 6; Move back and forth along the guide rail 6;

[0026] The gear box oil filling station 3 and the gear shaft oil filling station 4 are arranged side by side on the movable base plate 2; the gear box oil filling station 3 is provided with a gear box placement position 31 for placing a gear box 32; The gear shaft oiling station 4 is provided with a gear shaft placement position 41 and a rotating motor 42 for placing the gear shaft 43; the rotating motor 42 is fixed on the worktable 1, and its main shaft rotates with the gear shaft 43 connect;

[0027] The oil injection mechanism is mainly composed of a gearbox oil injection mechanism 8 and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap