Product turnover box logistics circulation process for cigarette factory

A turnover box and cigarette factory technology, applied in the direction of cooperative devices, instruments, packaging, etc., can solve problems such as extrusion, quality traceability, and affecting the quality of cigarettes, so as to reduce costs and avoid the process of conveying and packing cigarettes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

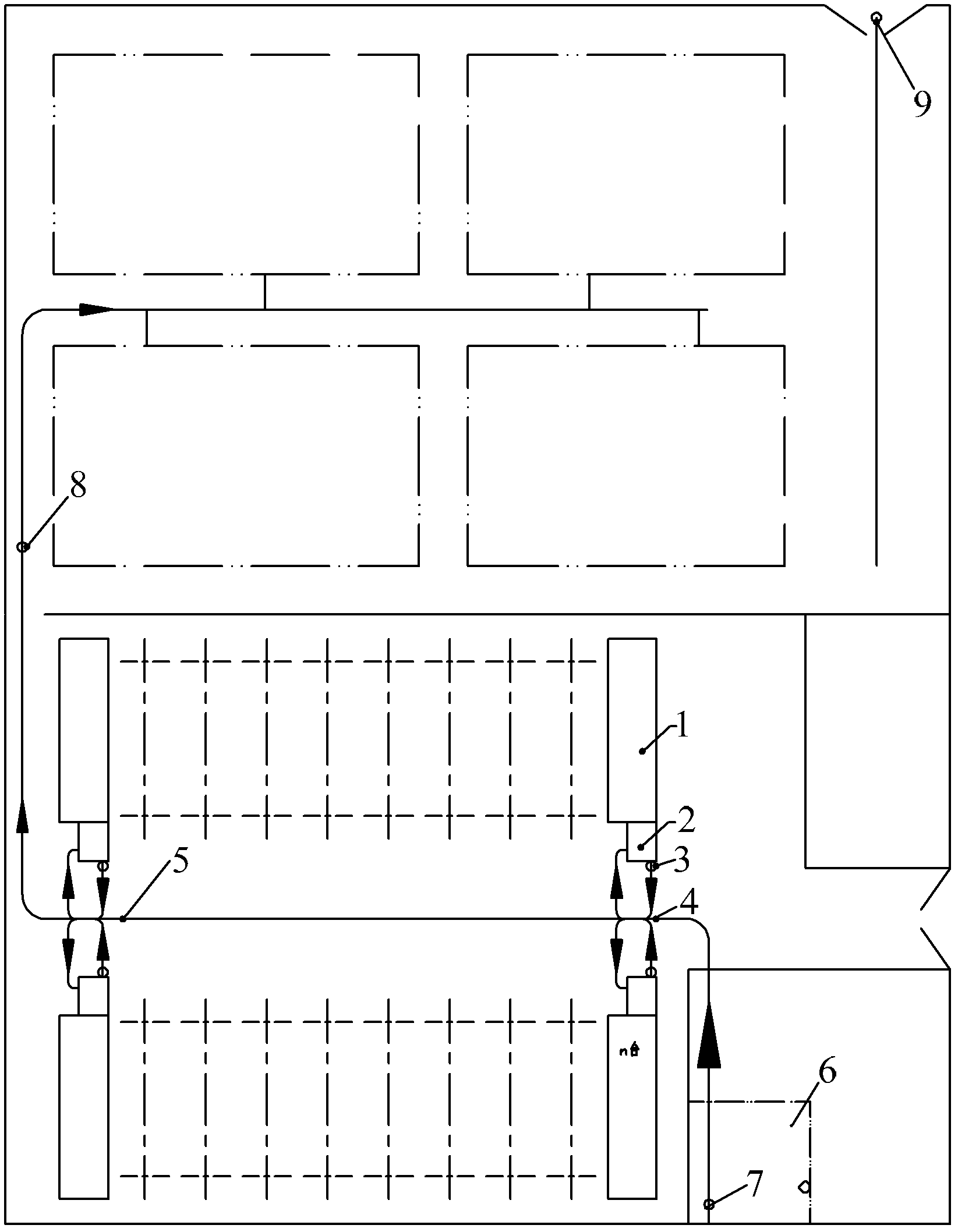

[0014] Such as figure 1 As shown, the present invention is used in the product turnover box logistics circulation process of cigarette factory and comprises the following steps: the empty turnover box recovered from the cigarette sorting and distribution center is sent to the empty box inspection and treatment area 6, and the empty turnover box is installed in the material center empty box The first RFID (Radio Frequency Identification, radio frequency identification) reader 7 at the entrance performs reading and writing verification, and the empty turnover boxes that fail to pass the verification are sent to the empty box manual processing area by the actuator for inspection or affixed with a new label. The qualified empty turnover boxes are sent to the box packing machine 2 by the empt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com