Design method of assembled-type prestressed concrete cylindrical column base

A design method and technology of precast concrete, applied in basic structure engineering, construction, etc., can solve the problems of difficult control of construction temperature cracks, lengthened construction period of foundation, increase of engineering quantity, etc., achieve good bearing effect of basic structure, reduce concrete and steel bars The effect of engineering quantity and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

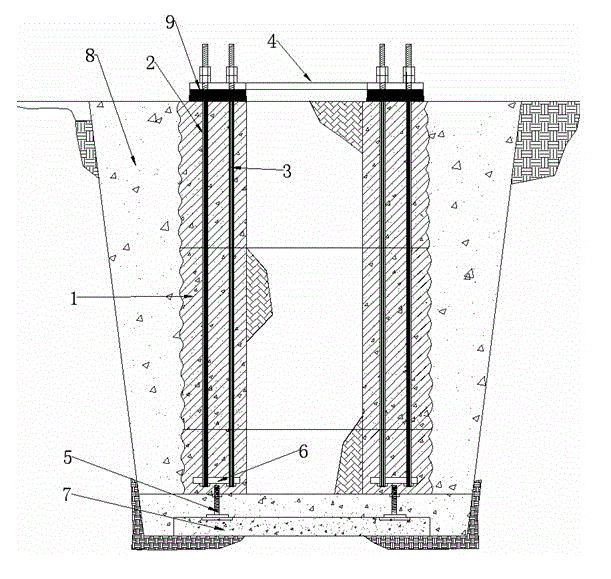

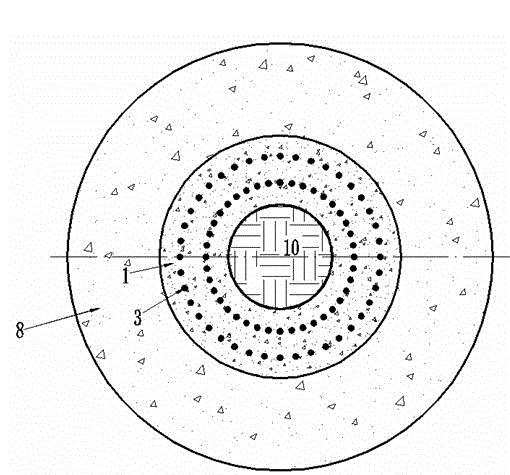

[0022] as attached figure 1 , figure 2 As shown, a design method of prefabricated prestressed concrete cylindrical column foundation, which is formed by assembling prefabricated concrete cylindrical column foundation, and then the concrete is in the In the pre-compressed state, the passive earth pressure of the soil outside the backfilled concrete of the prestressed concrete cylindrical column foundation after assembly is used to resist the load transmitted from the upper towering structure.

[0023] Assembling a prefabricated concrete cylindrical column includes a prefabricated cylindrical concrete column 1; a pre-embedded longitudinal casing 2 pre-embedded in the prefabricated cylindrical concrete column 1; extending through the pre-embedded longitudinal casing 2 to the The anchor cable 3 at the bottom end of the prefabricated cylindrical concrete cylinder 1 extends to the outside of the prefabricated cylindrical concrete cylinder 1 and connects with the high-strength conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com