Waterproofing agent for thermal insulation cement mortar, and application thereof

A cement mortar, thermal insulation technology, applied in the field of chemical materials, can solve problems such as damage, long construction time, poor thermal insulation effect, etc., and achieve the effect of ensuring strength requirements and ensuring waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

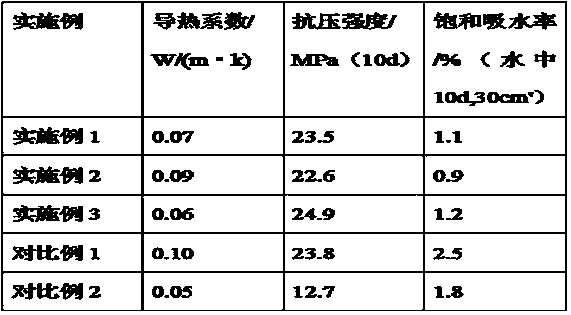

Embodiment 1

[0016] Embodiment 1: Thermal insulation cement mortar, including Portland cement, thermal insulation material and potassium salt of water repellent eicosic acid, the volume ratio of Portland cement and thermal insulation material is 1:2.5, after mixing, a block is formed , the relative density of the block is 352..6Kg / m 3, Then, 14.5% potassium salt of eicosic acid is added to the block to obtain the target product cement mortar.

Embodiment 2

[0017] Embodiment 2: thermal insulation cement mortar, including Portland cement, thermal insulation material and the potassium salt of water repellant eicosic acid, the volume ratio of Portland cement and thermal insulation material is 1:2.4, after mixing, form block , the relative density of the block is 364.5Kg / m 3, Then, 20% of the potassium salt of eicosic acid is added to the block to obtain the target product cement mortar.

Embodiment 3

[0018] Embodiment 3: thermal insulation cement mortar, including Portland cement, thermal insulation material and the potassium salt of water repellant eicosic acid, the volume ratio of Portland cement and thermal insulation material is 1:2.6, after mixing, form block , the relative density of the block is 346.0Kg / m 3, Then, 10.6% potassium salt of eicosic acid is added to the block to obtain the target product cement mortar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative density | aaaaa | aaaaa |

| Relative density | aaaaa | aaaaa |

| Relative density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com