A prestressed concrete steel composite tower capable of assembling a self-supporting wind power generating set and its anchoring method

A technology for wind turbines and anchoring methods, applied in the installation/support of wind turbine configuration, wind power generation, climate sustainability, etc., which can solve the problems of rapid construction of wind farms, long construction period of cast-in-place concrete towers, transportation problems, etc. Difficulty and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

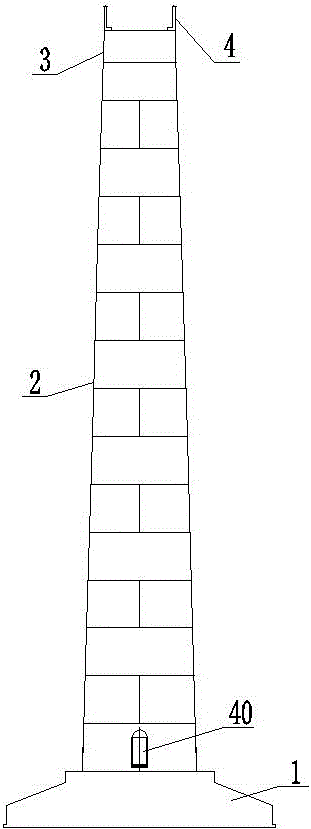

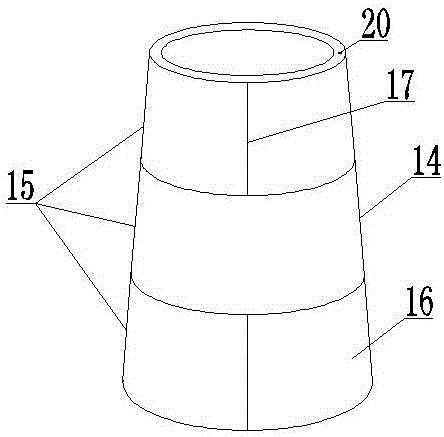

[0061] like figure 1 As shown, a self-supporting prestressed concrete steel composite tower for wind turbines includes a wind turbine foundation 1 and a steel tower section 4 above the wind turbine foundation 1, and also includes a prefabricated concrete tower section 2 and a prefabricated concrete conversion section 3 , the fan foundation 1 , the precast concrete tower section 2 , the precast concrete conversion section 3 , and the steel tower section 4 are connected by prestressed anchor beams 54 sequentially from bottom to top. In this embodiment, part of the tower section is replaced with concrete for the steel tower, which can effectively reduce the cost.

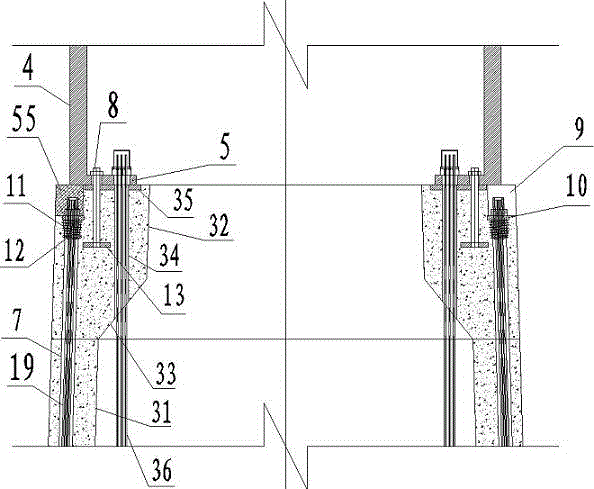

[0062] from figure 1 , 2 , 3, 4, it can be seen that the bottom of the steel tower section 4 is provided with a T-shaped or L-shaped flange 5, and holes are reserved on the flange 5, and the prestressed anchor beam 54 includes the internal prestressed anchor beam 19 and The external prestressed anchor bundle 36, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com