Intelligent digital capacitive liquid level sensor

A capacitive liquid level sensor technology, applied in the field of liquid level sensors, to achieve high-precision measurement and display, simple and easy calibration, and accurate and stable signal output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

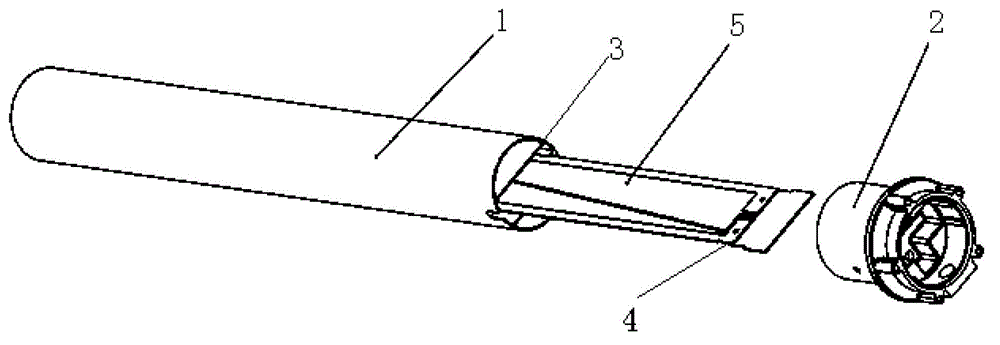

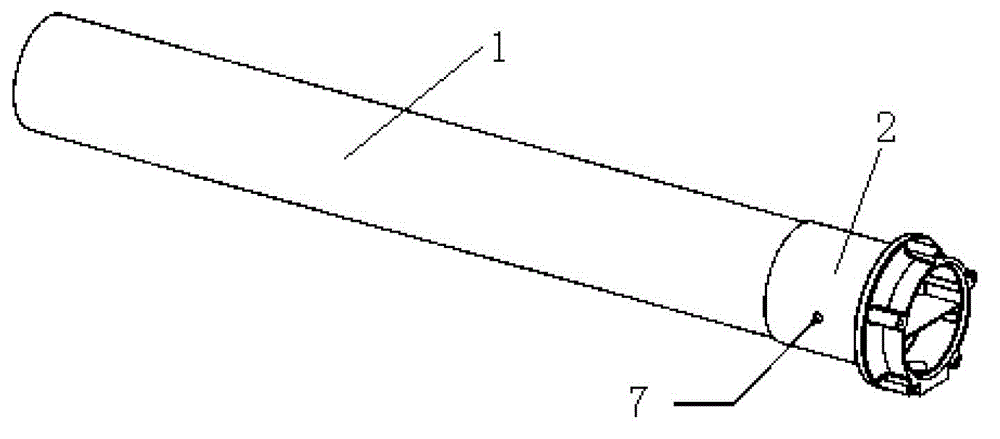

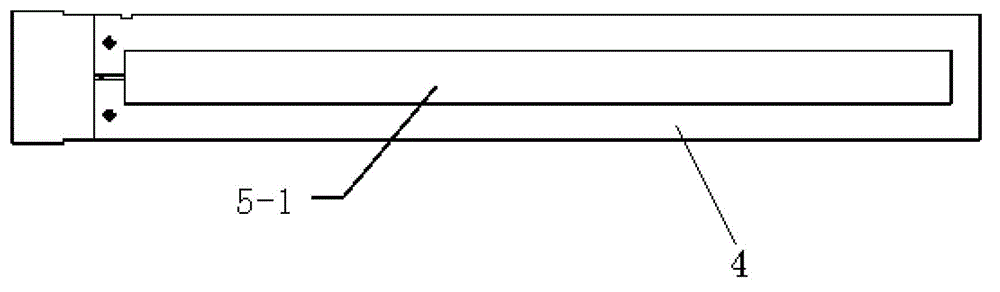

[0029] Referring to the accompanying drawings, an intelligent digital capacitive liquid level sensor includes a cylinder body 1, a top seat 2 is mounted on the top of the cylinder body 1, a data acquisition and processing circuit board is arranged inside the top seat 2, and a pair of The card slots 3 correspond to each other, and the circuit board body 4 is installed in the card slot 3. The circuit board body 4 is covered with one or two pieces of copper foil 5 independent of each other. The surface of the copper foil 5 is covered with a solder resist insulating material for contact with The liquid to be tested is isolated and insulated, and a metal plate 6 parallel to the circuit board body 4 is also provided in the cylinder body 1. The metal plate 6 and the circuit board body 4 constitute the capacitance probe of the sensor, and the output of the capacitance probe and the circuit board part of the data acquisition and processing circuit Connected together, and the data acquis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com