Solar glass reinforced plastic back plate condensing lens assembly and processing method thereof

A technology of condensing lens and processing method, applied in optical components, chemical instruments and methods, optics, etc., can solve the problems of poor aging resistance, high profile error, low reflectivity of condensing lens components, etc. of plastic lenses and plastic backplanes , to achieve the effect of enhancing environmental adaptability, high light transmittance and reflectivity, and simple molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

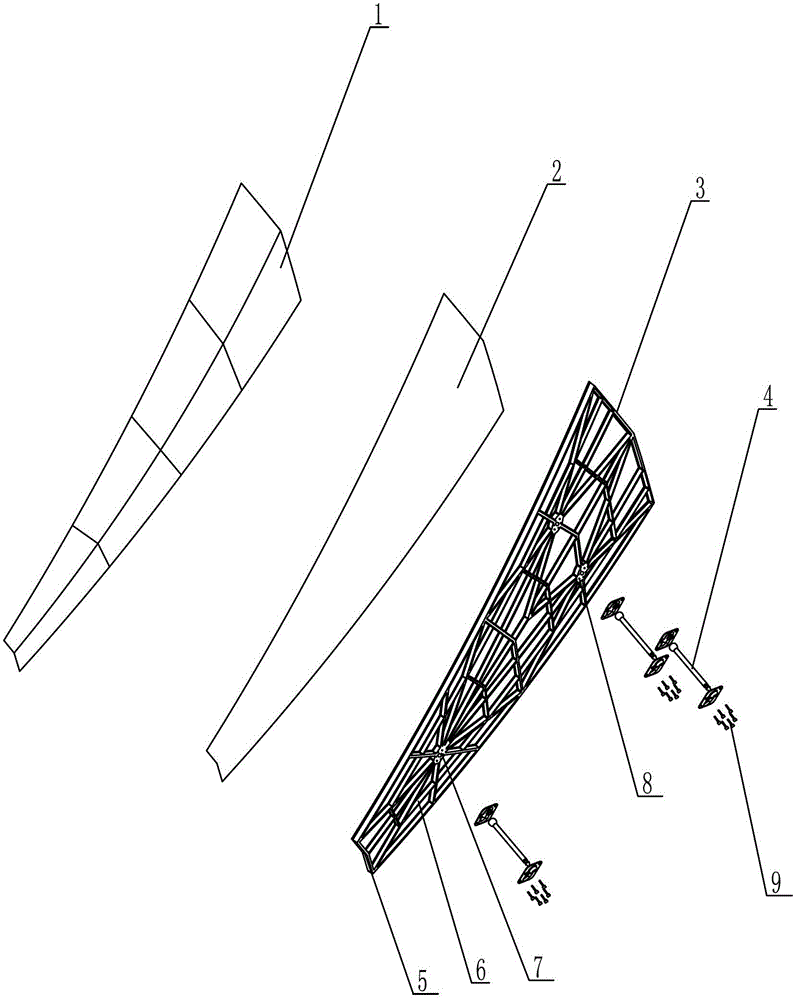

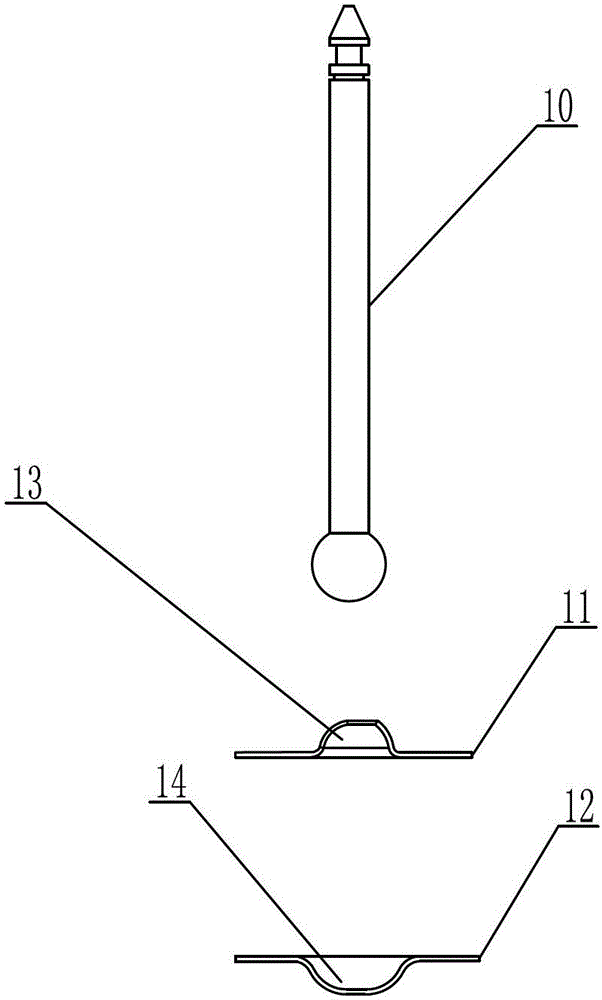

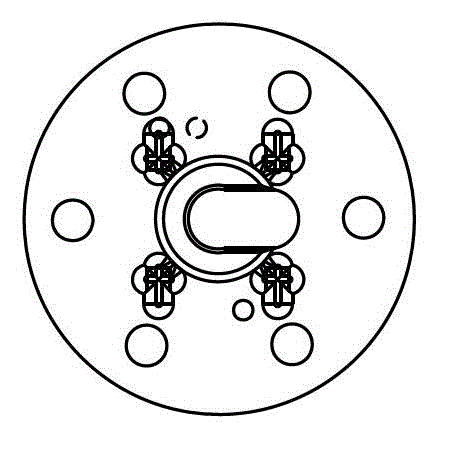

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 A solar fiberglass backplane concentrating lens assembly shown includes a lens group 1, a fiberglass backboard 3 and a support component 4; the lens group 1 is composed of a plurality of ultra-thin flat glass lenses; the front of the lens group 1 is fan-shaped , the side is arc-shaped; the FRP backboard 3 is made of SMC molded FRP; the backside of the FRP backboard 3 is provided with reinforcing ribs 6 and three support seats 7 that are connected with the support assembly 4, and each support Several nuts 8 are pre-embedded on the seat 7; the two ends of the glass fiber reinforced plastic back plate 3 are provided with limiting steps 5 for fixing the lens group 1; the support assembly 4 includes a support rod 10, an upper cover plate 11 and a lower cover plate 12 One end of the support rod 10 is provided with a sphere, and the other end is provided with a cone, and the rod connects the sphere and the c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap