Atomization device and ultrasonic humidifier

A technology of atomization device and transducer, which is applied to spray device, liquid spray device, air humidification system, etc., can solve the problems of complicated operation, high processing and manufacturing cost, complicated manufacturing process, etc., so as to reduce the manufacturing cost and simplify the structure. , the effect of reducing the difficulty of the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

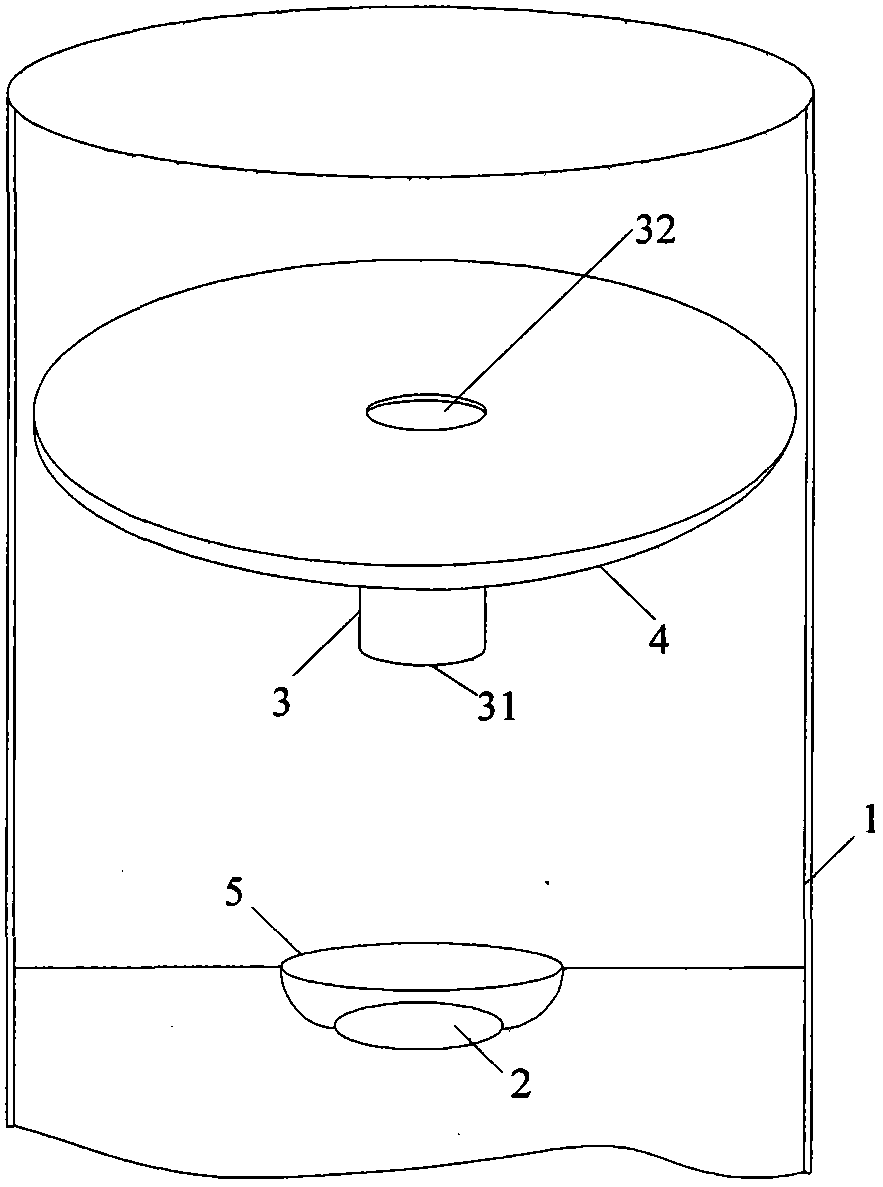

[0029] The present invention proposes an atomization device and an ultrasonic humidifier, in which an atomization enhancement part is set floating in the liquid above the transducer, so that the liquid above the transducer can produce a better atomization effect when it is at any liquid level . Since the present invention can work normally when the liquid on the transducer is at any liquid level that changes dynamically, it is no longer necessary to use the bottom structure of the water tank assembly to control the liquid level on the transducer to keep fixed, so that it can get rid of the ultrasonic wave The humidifier relies on the water tank components to achieve the purpose of simplifying the structure and improving the atomization effect.

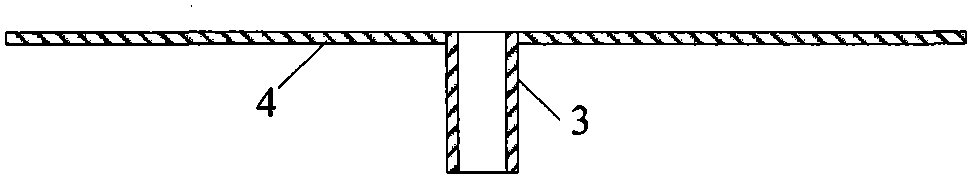

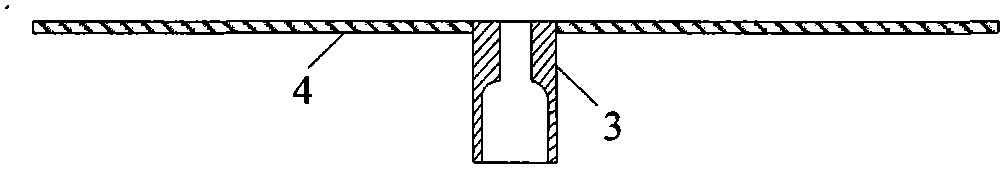

[0030] like figure 1 As shown, the atomization device proposed by the present invention includes: a water tank 1 for containing atomized liquid (such as water, medicament, fragrance, etc.), the bottom of the water tank 1 is fixed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com