Self driven rotating pulse detonation cleaning system

A technology for pulse detonation, cleaning systems, applied in vibration cleaning, cleaning heat transfer devices, cleaning methods and utensils, etc., can solve the problems of operation and maintenance complexity, undesired, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Exemplary embodiments incorporating one or more aspects of the present invention are described and illustrated in the drawings. These examples are not intended to limit the invention. For example, one or more aspects of the invention can be used in other embodiments and even in additional device types. Furthermore, certain terms are used herein for convenience only and should not be considered as limiting the invention. In addition, in the drawings, the same reference numerals are used to designate the same elements.

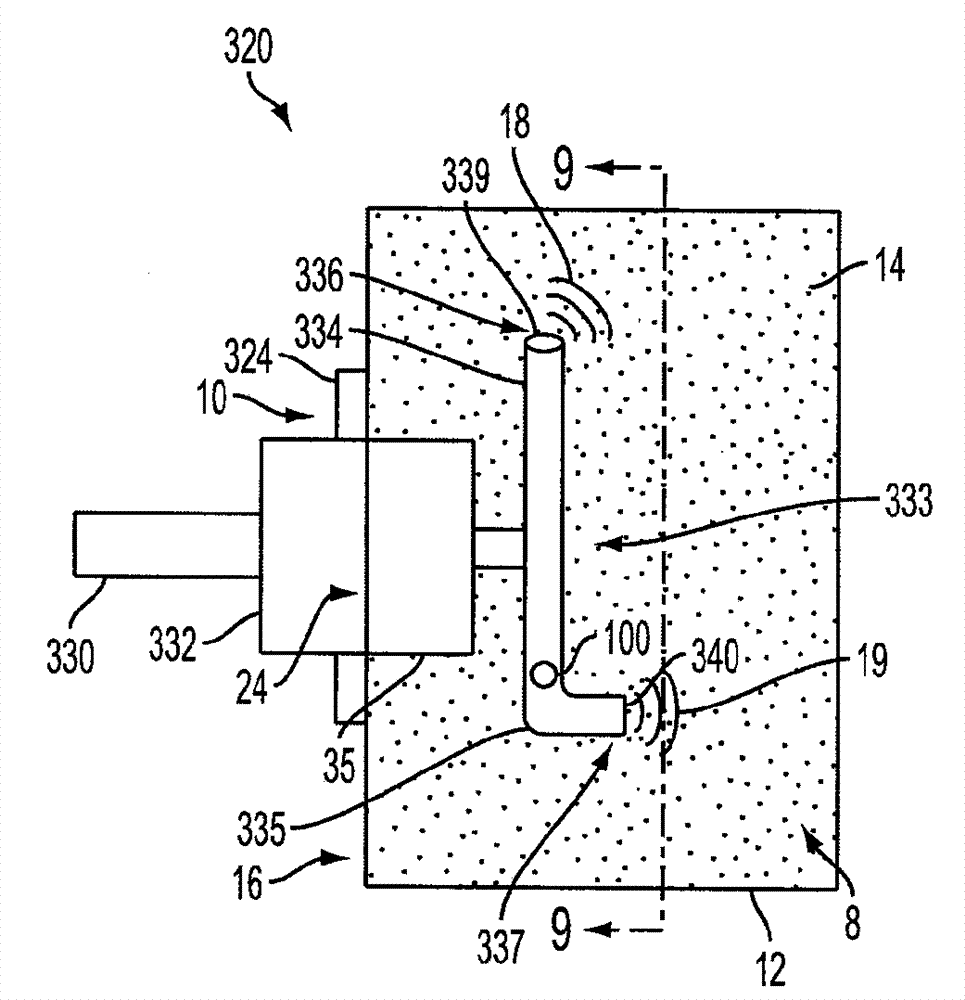

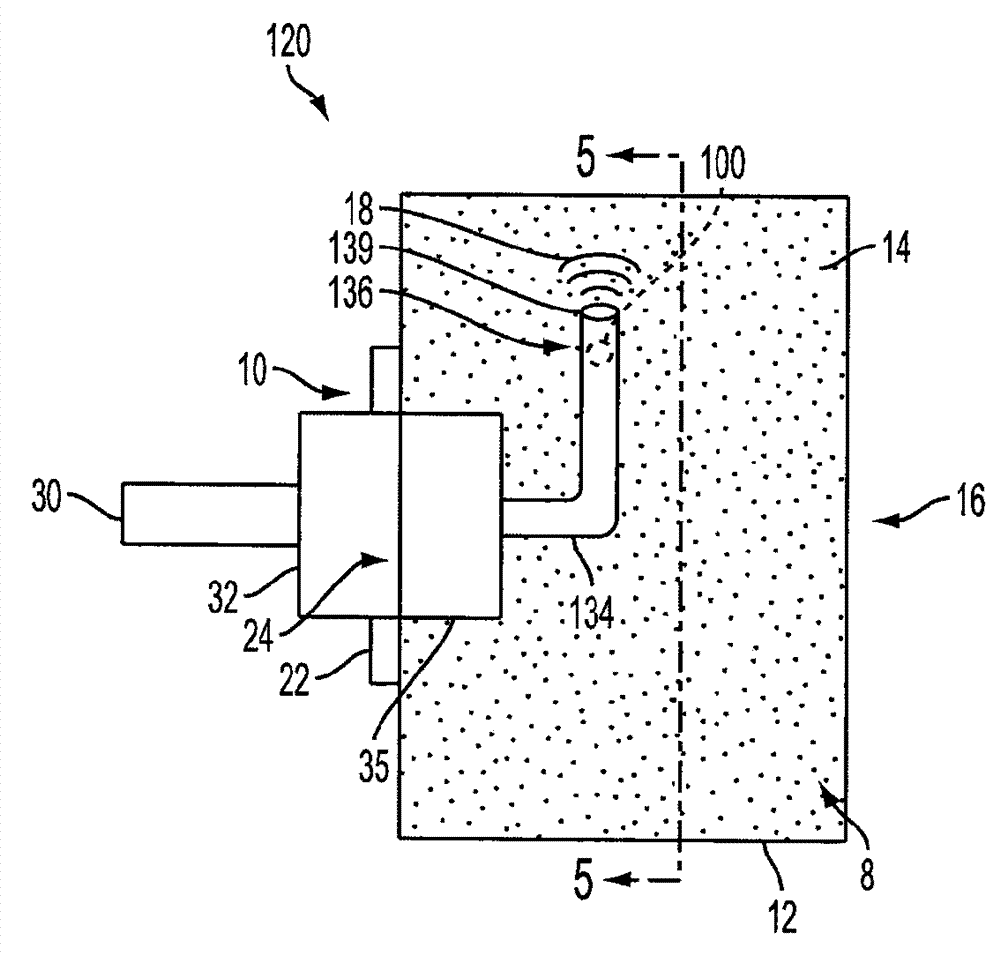

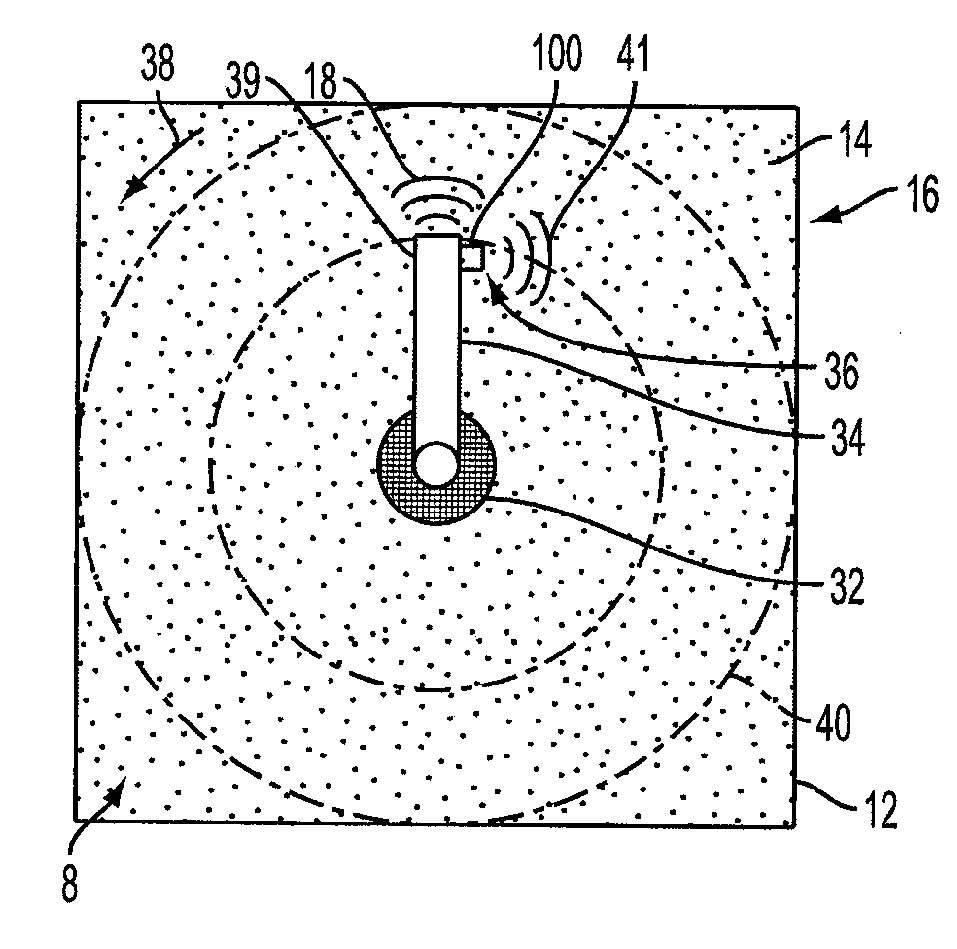

[0018] figure 1 A pulse detonation cleaning system 10 according to one aspect of the invention is shown. Pulse detonation cleaning system 10 may include one or more pulse detonation devices 20 associated with operating device 12 . In the illustrated example, the pulse detonation device 20 comprises a single pulse detonation device associated with the operating device 12 .

[0019] It should be appreciated that the operating device 12 is only shown ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com