Hot continuous rolling coiler parallel side guide plate control method

A control method and side guide technology are applied in the field of parallel side guide control of a hot continuous rolling coiler, which can solve the problems of slow closing speed, long closing time, and easy occurrence of steel stuck accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

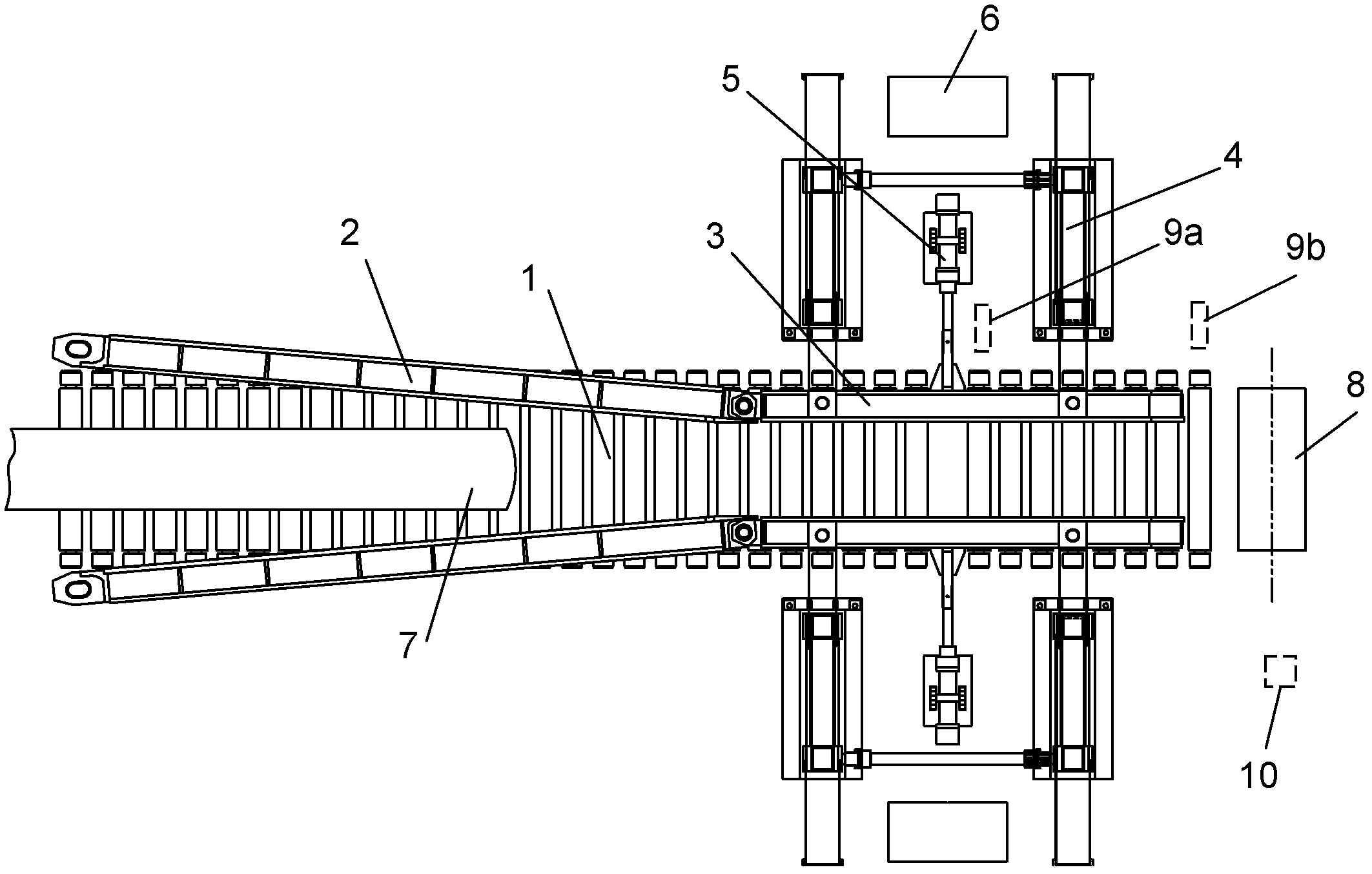

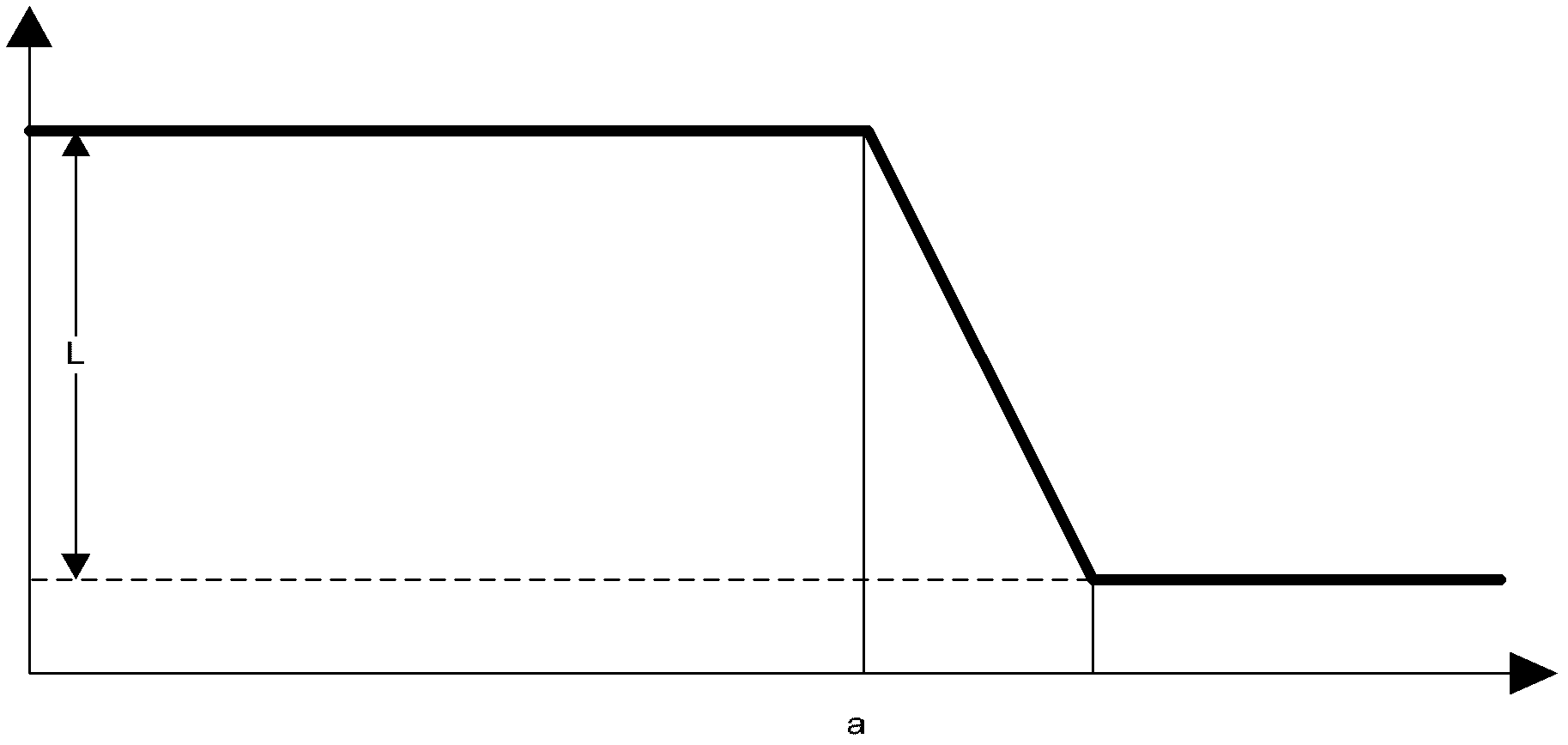

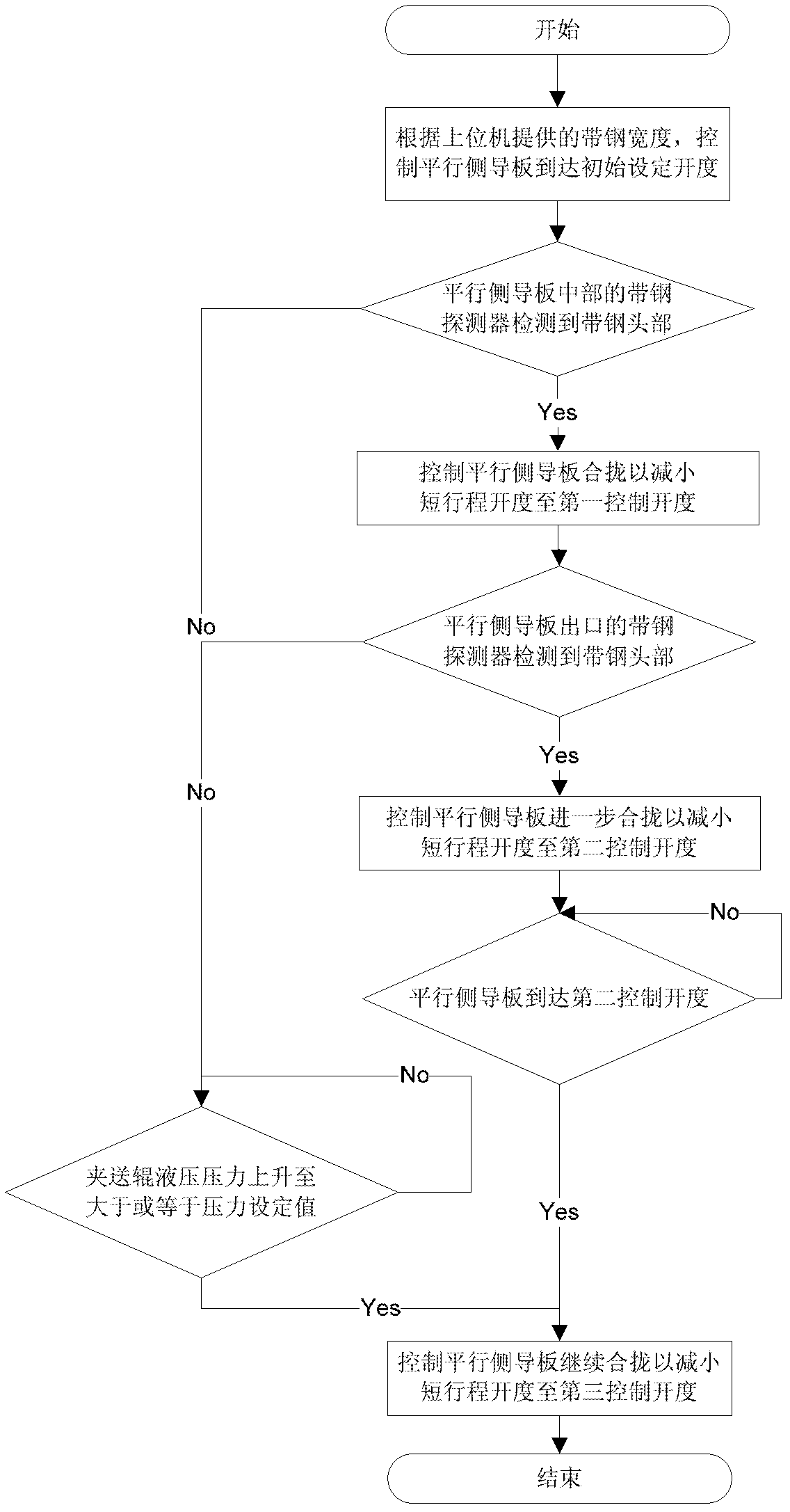

[0033] Please combine figure 1 , image 3 , Figure 4 As shown, the hot rolling coiler parallel side guide plate control method of the present invention mainly comprises:

[0034] The method for controlling the parallel side guide plate of the hot continuous rolling coiler includes the following specific steps:

[0035] Firstly, strip steel detectors 9a and 9b are respectively provided at the middle and exit of the parallel side guide plate 3 to detect the running position of the strip steel 7 . The strip steel detectors 9a, 9b can be hot metal detectors or laser detectors.

[0036] Then a pressure sensor 10 is set on the pinch roller hydraulic cylinder, and the hydraulic pressure of the pinch roller 8 is also used to detect the running position of the strip steel 7 .

[0037] When the coiling starts, according to the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com