A Method for Reducing Welding Residual Stress of Orthotropic Steel Bridge Deck

A residual stress and orthotropic technology, applied in the field of bridge manufacturing, can solve problems such as the inability to reduce the welding residual stress of orthotropic steel bridge decks, and achieve the effects of high energy consumption in smelting, strong pertinence, and increased fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

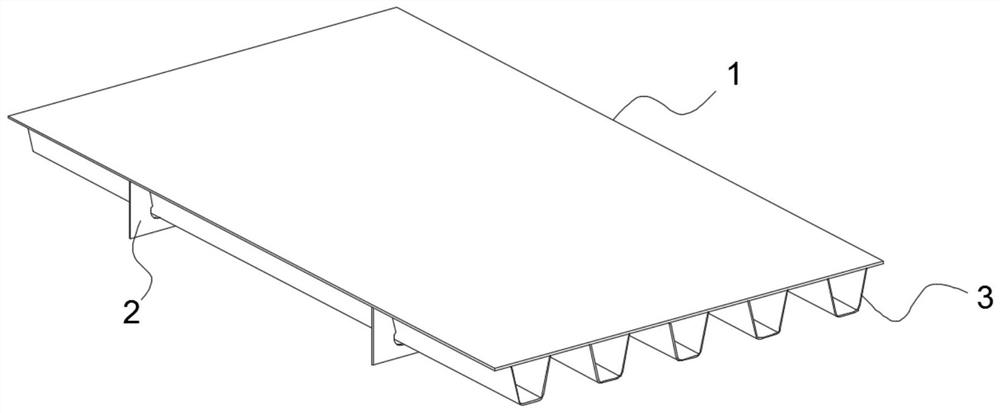

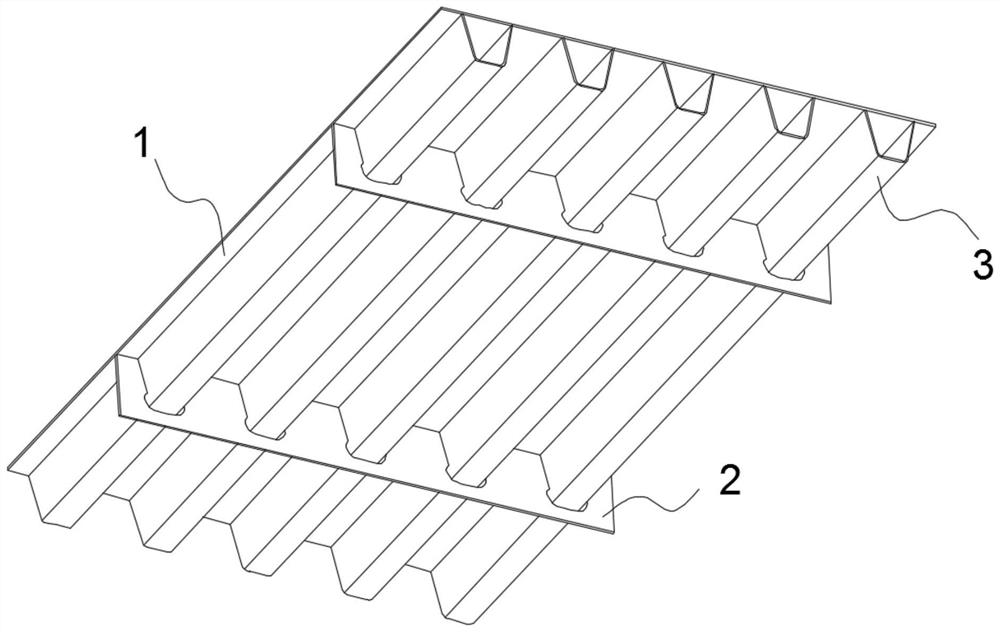

[0046] This embodiment takes a typical orthotropic steel deck as an example to illustrate the method for reducing the welding residual stress of an orthotropic steel deck in the present invention. There is a significant difference in the longitudinal stiffness and transverse stiffness of an orthotropic steel deck. Such as figure 1 and figure 2 As shown, the orthotropic steel deck includes a steel roof 1, and longitudinal ribs 2 welded to the lower surface of the steel roof 1. The number of longitudinal ribs 2 is two, and the longitudinal ribs 2 are arranged along the transverse direction of the steel roof 1; 2 and the steel roof 1 are provided with 5 transverse ribs 3, the transverse ribs 3 are arranged along the longitudinal direction of the steel roof 1, the longitudinal ribs 2 and the steel roof 1 are welded with the transverse ribs 3; the thickness of the steel roof 1 is 14-24mm , the thickness of the longitudinal ribs 2 is 8-12mm, the thickness of the transverse ribs 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com